60

Rubberized Asphalt

Polyurethane

40

Silicone

Polysulfide

Preformed

20

0

0

10

20

30

40

50

60

Time (min)

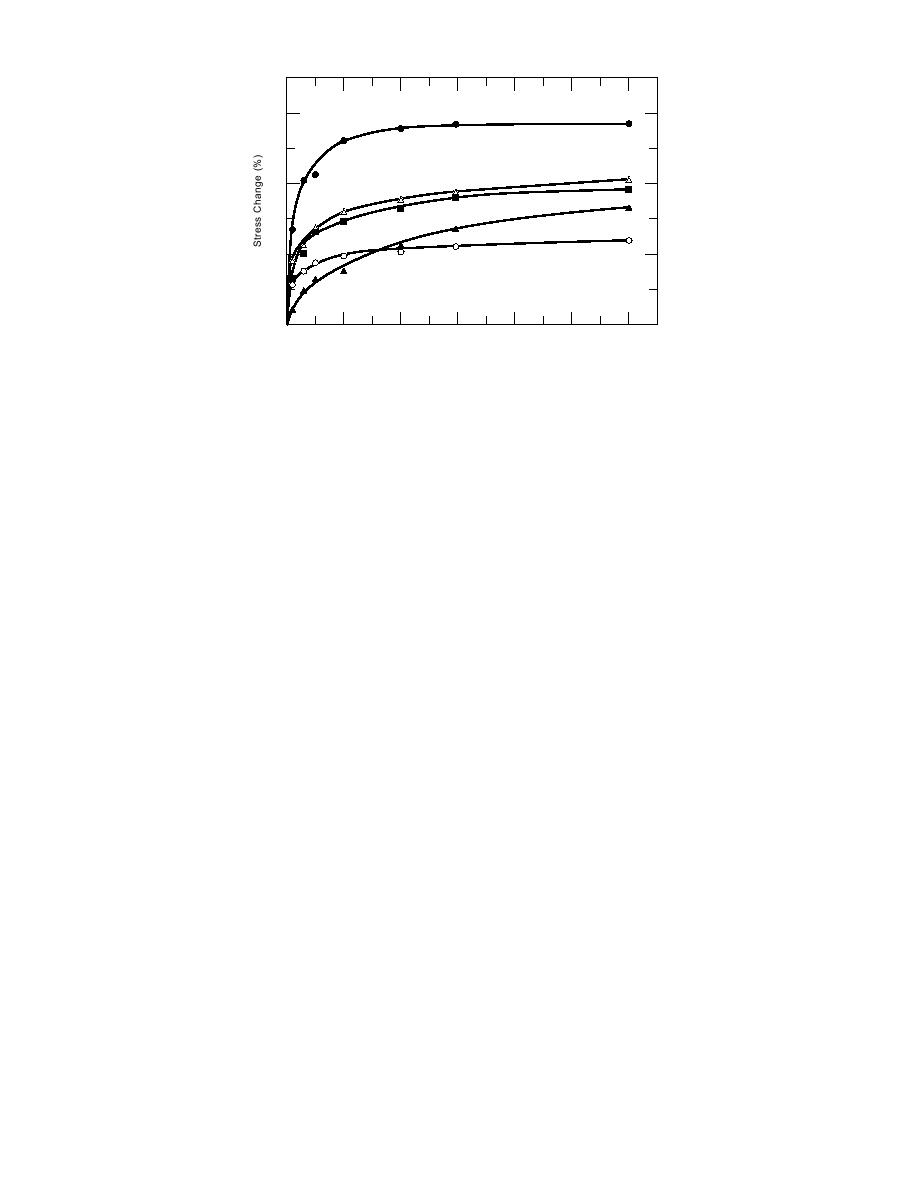

Figure 16. Results from step deformation tests of butt joint seal

specimens formed from various sealants. (From Collins et al. 1986.)

The load and deformation responses shown

viscoelastically to any thermally or load-induced

in Figure 14, as well as secant stiffness values of

movement of the joint without failure of the seal

the model seals for 50% extension reported by

or the adhesive bond, and that it cure to a suffi-

Collins et al. (1986), show that significant stiffen-

cient hardness and remain sufficiently hard so that

ing of the responses occurred at 7C for all of the

it will not be damaged by indentation of harder

materials except the silicone sealant. The stiffen-

objects. Because joint movements are often large,

ing of the rubberized asphalt seal due to the tem-

joint seals must be expected to withstand large de-

perature reduction was extreme.

formations. Winter conditions are recognized as

Results from step deformation tests of poly-

the most critical for a seal because of the possibil-

sulfide butt joint seal specimens performed by

ity that failure stresses will be reached in the seal

Cook (1965) are shown in Figure 15. The load vs.

or at the adhesive interface as the joint opens and

time curve in Figure 15 reflects the stressrelaxa-

the material stiffens in response to the tempera-

tion material response and the viscous nature of

ture reduction. For all conditions the ideal behav-

the polysulfide sealant. Results from similar ex-

ior of a pavement joint seal is that of an elastomer.

periments reported by Collins et al. (1986) are

As a result sealants have been formulated with a

shown in Figure 16. These tests were conducted

rubber or elastomer as a base material in order to

at 22C (72F) using the materials of Figure 14

have relatively low resistance to load at low tem-

and the model seal geometry described above for

peratures.

the joint extension tests of Collins et al. (1986).

Pavement joint sealants that include a rubber

The measurements were made after extending

or elastomer as a base material are, in essence, elas-

the model seals 50% at a deformation rate of 25

tomeric compounds, and should be considered as

cm/min. The percent change in the nominal stress

such for research and engineering applications. Al-

vs. time is shown in Figure 16. It is interesting to

though plastic behavior is observed in the response

note that while all of the responses shown in this

of some sealant compounds containing elastomers,

figure reveal viscous behavior, as suggested by

in general these sealants are formulated and pro-

Collins et al. some of the behavior is viscoelastic

moted to behave with rubber-like characteristics.

and some viscoplastic. Without unloading curves

To describe the mechanical properties of these seal-

this distinction cannot be made, however.

ants it is helpful to consider sealant behavior in

the context of the behavior of rubbers and elas-

tomers since the material response features of prac-

SUMMARY AND

tical interest for sealing joints are clearly revealed,

RECOMMENDATIONS

and since the elastomeric qualities that a seal dis-

plays when subjected to field loadings and condi-

The primary mechanical requirements of a pave-

tions can be used to judge the effectiveness of the

ment joint seal are that it respond elastically or

sealant. Implicit in any description of an elasto-

17

Previous Page

Previous Page