ing rates of 3.8 and 2.1 mm/hr. The pattern is consis-

high concentration in the first segment can be explained

tent with the mechanism of the freeze concentration

by the fact that the freezing rate was probably faster

process discussed earlier.

near the aluminum end cap, which has a greater heat

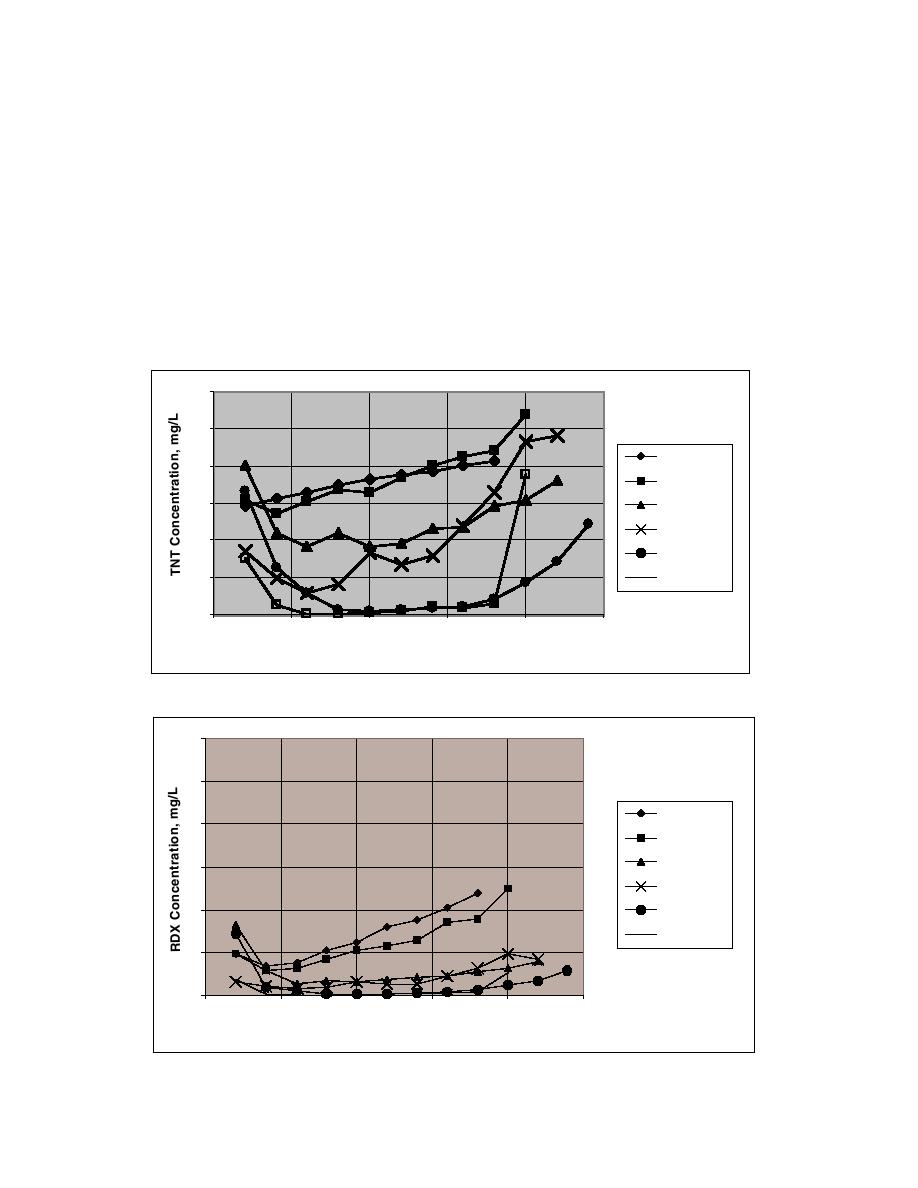

The plots in Figure 4 show that the TNT concentra-

transfer capacity than ice. From 2 cm to 16 cm, TNT

tion in the ice cylinders varied according to freezing

inclusion was relatively constant, although the concen-

distance. For example, at the 6.7 mm/hr freezing rate,

tration of TNT in the residuals was increasing. Beyond

the average TNT concentration in the first 2 cm of ice

16 cm, the TNT concentration in the residual ahead of

was 20.22 mg/L. In the second 2 cm of ice (freezing

the freezing front was too great to continue the rejec-

distance = 4 cm), the TNT concentration dropped to

tion rate, and so more TNT was included in the ice

11.01 mg/L. From this point to a freezing distance of

cylinder. The higher concentration in the end segment

16 cm, the TNT concentration varied only slightly from

was probably caused by the inclusion of rejected con-

9.20 mg/L to 11.86 mg/L. At 18 cm, the TNT concen-

taminants attached to the end of the segment.

tration jumped up to 14.76 mg/L and continued to climb

The effect of freeze concentration on RDX is shown

to 15.52 mg/L at 20 cm, and 18.03 mg/L at 22 cm. The

in Figure 5. The freeze concentration effect is similar

30

25

11.7 mm/hr

11.7 mm/h

20

9.4 mm/hr

9.4 mm/hr

6.7 mm/hr

6.7 mm/hr

15

5.4 mm/hr

5 .4 mm/hr

3 8 mm/hr

10

2.1 mm/hr

3.8 mm/hr

2.1 mm/hr

5

0

0

5

10

15

20

25

Freezing Distance

Figure 4. TNT concentration in ice cylinder at each freezing rate.

30

25

11.7.mm/hr

11 7 mm/hr

20

9.4.mm/hr

9 4 mm/hr

6.7.mm/hr

6 7 mm/hr

15

5.4.mm/hr

5 4 mm/hr

3.8.mm/hr

3 8 mm/hr

10

2.1.mm/hr

2 1 mm/hr

5

0

0

5

10

15

20

25

Freezing Distance, cm

Figure 5. RDX concentration in ice cylinder at each freezing rate.

5

Previous Page

Previous Page