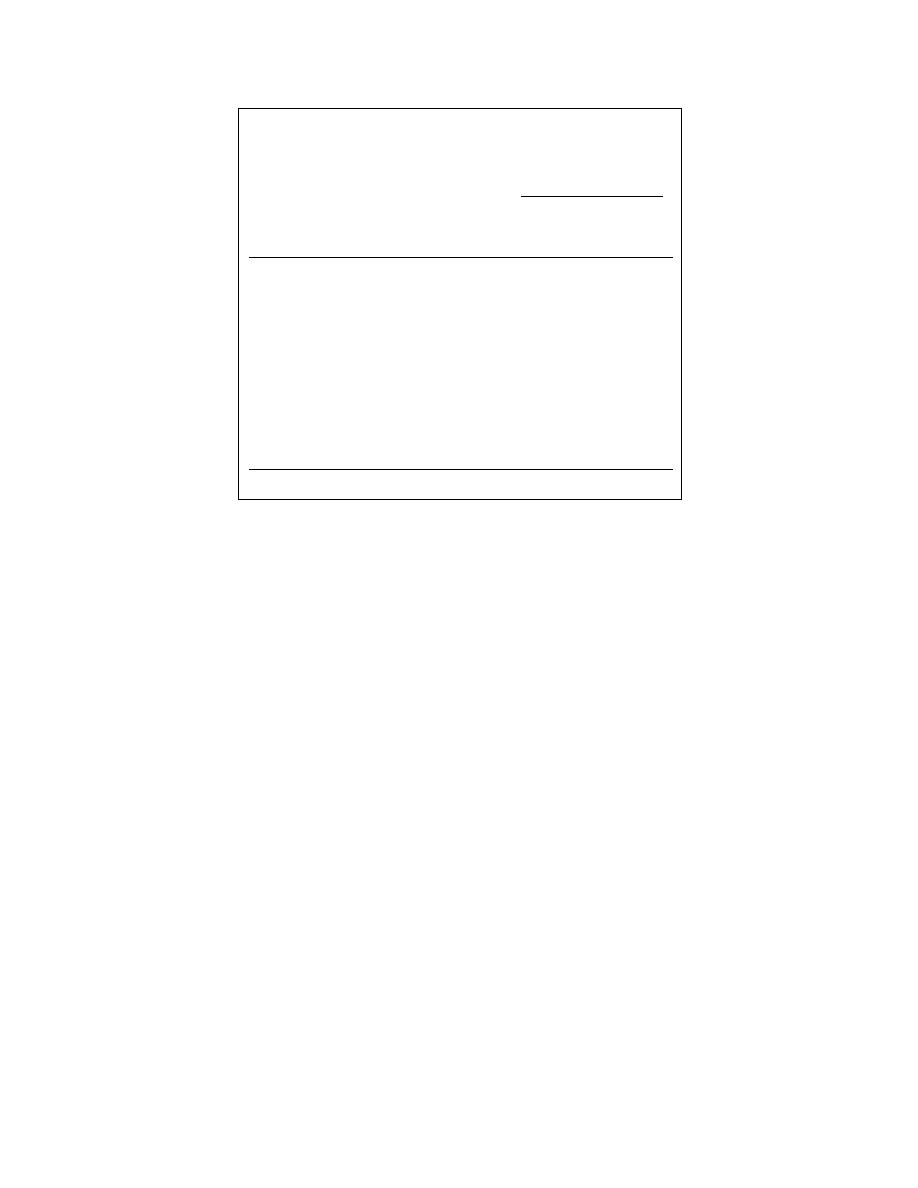

Table 8. Percent recoveries and relative standard deviations esti-

mated by the off-site laboratories and on-site by the technology

developer for the performance evaluation materials.

Hanby

CRREL

Ref. Lab

HM 2000

Sample

% Recov.

% Recov.

Visual

% Recov

no./ID

(% RSD)

(% RSD)

% Recov.

(% RSD)

GRO

SG-1, 2, 3, 4

99

112

160

310

(200 mg TPH/kg)

(8.6)

(4.4)

(38)

WG-1, 2, 3, 4

100

102

430

480

(1.0 mg TPH/L)

(7.0)

(10.2)

DRO

SDM-1, 2, 3, 4

NA

134

300

270

(401 mg TPH/kg)

(7.0)

(56)

SDM-25, 26, 27, 28

NA

177

270

290

(2480 mg TPH/kg)

(22.7)*

(35)

* Only two of the four replicates were analyzed.

(Tables 9 and 10) and were on average 35% for the HM

day was continued. Visual and HM 2010 measurements

were made on 34 of the 36 samples distributed.

2000 method. The precision of the visual method was

On the second day of the field exercise, the HM

not assessed because estimates arise from a discontinu-

2000 experienced another software failure after the 16

ous scale and are subjective.

water samples contaminated with DRO/bunker C had

The sampling team distributed 90 samples for on-

been analyzed. This could not be corrected during the

site analysis during the 2.5-day exercise. On the first

technology demonstration. At about the same time the

day, 20 soil and 16 water samples contaminated with

HM 2000 failed, the HM 2010 also failed because of a

GRO compounds were distributed. On the second day,

low battery charge. The combination of these two prob-

36 soil samples and 16 water samples were distributed.

lems forced the technology developer to treat 38

Of the soils distributed on day two, 27 were contami-

samples (36 soil samples and 2 water matrix spikes) by

nated by DRO/bunker C and 9 were contaminated by

taking them through the solvent extraction step, then

RRO compounds. All 16 water samples were contami-

shipping them off-site prior to adding the catalyst and

nated with DRO/bunker C. On the morning of the last

completing the analysis.

day, two water samples with DRO contamination were

The large amount of time spent to address these

distributed. The technology developer agreed to ana-

problems limited the time available to prepare a data

lyze the large number of samples on the second day of

report. As a result, no TPH values were reported dur-

the field exercise.

ing the technology demonstration; however, a prelimi-

The technology developer analyzed all of the 20 soil

nary data report was made available on the following

samples distributed on the first day; however, while

Monday (the technology demonstration finished on a

analyzing the 16 water samples, the HM 2000 instru-

Friday). This initial data report showed that of the 90

ment developed a software problem that required off-

samples distributed, 52 samples (58%) were analyzed

site assistance. When it became clear that the HM 2000

on-site by the visual comparison and the HM 2010

would be unable to continue, the technology developer

methods, and 47 samples (53%) had been analyzed by

chose to hold some of the sample extracts overnight,

the HM 2000. Preliminary TPH values were reported

prior to adding the catalyst and forming the Friedel-

at this time for the visual and HM 2000 methods of

Crafts reaction products. Because of this interruption,

analysis; however, none were reported for the HM 2010.

five water samples were not analyzed by the HM 2000

system. On the morning of the second day, the HM 2000

During this field exercise, the HM 2010 was only

system was brought back on-line and the analysis of

capable of producing voltage responses because of an

the water samples that had been distributed on the first

integrated circuit failure, and calibration models for the

13

Previous Page

Previous Page