face. Since the frictional force between the tire and

different minerals present in the aggregate (Trem-

the pavement surface is a function of the vehicle

blay et al. 1995).

speed, it is usually reported at a speed of 65 km/

The macroscopic roughness is provided by

hr. The frictional coefficient is multiplied by 100

spacing between the aggregate from 0.5 to 50 mm

and reported as the skid number (SN).

(horizontal) and 0.2 to 10 mm (vertical) (Donbav-

and 1989). This spacing provides channels for

rapid drainage of water from the surface and is

Roughness and texture

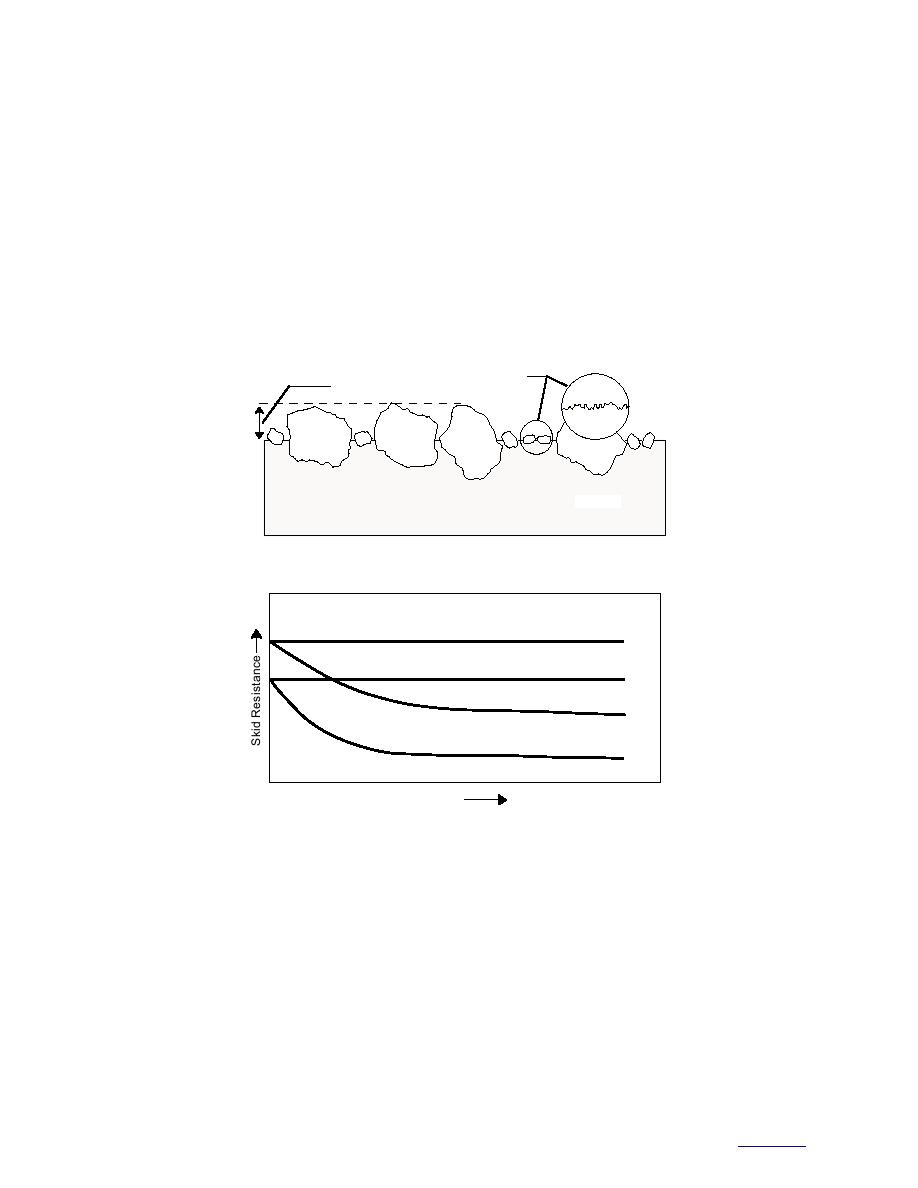

The microscopic and macroscopic roughness

important at vehicle speeds greater than 50 km/

are characterized by the texture of the aggregate

hr (Donbavand 1989). Therefore, at speeds higher

surface and by the overall roughness of the pave-

than 50 km/hr, the skid resistance depends pri-

ment surface due to protrusion of the aggregate

marily on the spacing provided by the coarse

surfaces, respectively. Macro- and microtextures are

aggregates (Beaton 1976).

illustrated in Figure 13. Macrotexture has the great-

The microtexture refers to the irregularities on

Microtexture

Macrotexture

BINDER

Figure 13. Road surfacing textural characteristics (Tremblay 1995).

GooodMacrrotextturre, Good Miicrrottextture

G od Macote x u e

M c o exure

PPoorMiccrotexturre,, Good Macrottextture

oor Mi rotext u e

cro exure

GooodMiccrotextturre,, Poor Macrottextture

G od Mi rotex u e

cro exure

PPoorMiccrotexturre,, Poor Macrottextture

oor Mi rotext u e Poor Macro exure

Speeded

Spe

Figure 14. Correlation between macrotexture, microtexture, skid

resistance, and speed (Tremblay 1995).

est influence on the change in friction with speed.

the surface of the coarse and fine aggregates. It is

Figure 14 illustrates the effect of the macro- and

also affected by the amount of fines in the HMA

mix (Tremblay et al. 1995). The effect of different

microtextures on skid resistance as a function of

types of pavement surfaces on the macro- and

speed. Clearly, to maintain a constant high skid

microtextures is illustrated in Figure 15. The

resistance value at various speed levels, the pave-

terms viscous and dynamic fluid pressure allevi-

ment surface has to have both good macro- and

ation in Figure 15 relate to the natural flow and

microtextures. The change in the texture depends

flow under the impact of a moving tire. The effect

on the aggregate resistance to fragmentation, wear,

of texture on skid resistance is shown in Figure

and polishing. Aggregate fragmentation and wear

16. Several observations can be made. First, the

depend on the toughness and hardness of the

microtexture can provide adequate skid resis-

aggregate minerals and the aggregate itself. Pol-

tance at lower speeds, such as in urban areas (line

ishing depends on the difference in hardness of the

10

to contents

Previous Page

Previous Page