limited tests, the flow coefficient for crushed

from 19 to 25 mm, 25 to 9.5 mm, and 9.5 mm to no.

gravel was 92.2 and for crushed stone was 115

4 are tested separately and the UCV averaged

(Janoo 1998).

from the individual fraction sizes. As shown in

Figure 11a, the modified NAA method developed

by Aldrich (1996) for the coarse fraction of the

Characterization summary

In summary, it was found that several methods

HMA mixture clearly indicates that the UCV in-

are available for characterizing the shape, angu-

creases with increasing percent of crushed coarse

larity, and surface texture of HMA aggregates. It is

particles. In addition, Aldrich (1996) showed a

good correlation between the results from the

difficult to separate the effect of individual fea-

modified NAA test for coarse aggregates and the

tures of the aggregate, with the exception of petro-

particle index value (Figure 11b). Overall, this is a

graphic methods. All of the tests tend to provide

fairly simple test to conduct, and correlation be-

the effect of the overall shape, angularity, and

tween rutting potential and aggregate character-

roughness. The NAA and modified NAA tests

ization can be easily developed.

seem the easiest to use and implement. The time

flow test used by the Quebec Ministry of Trans-

portation also appears to be easy to implement.

Time index

Similar in concept to the uncompacted void

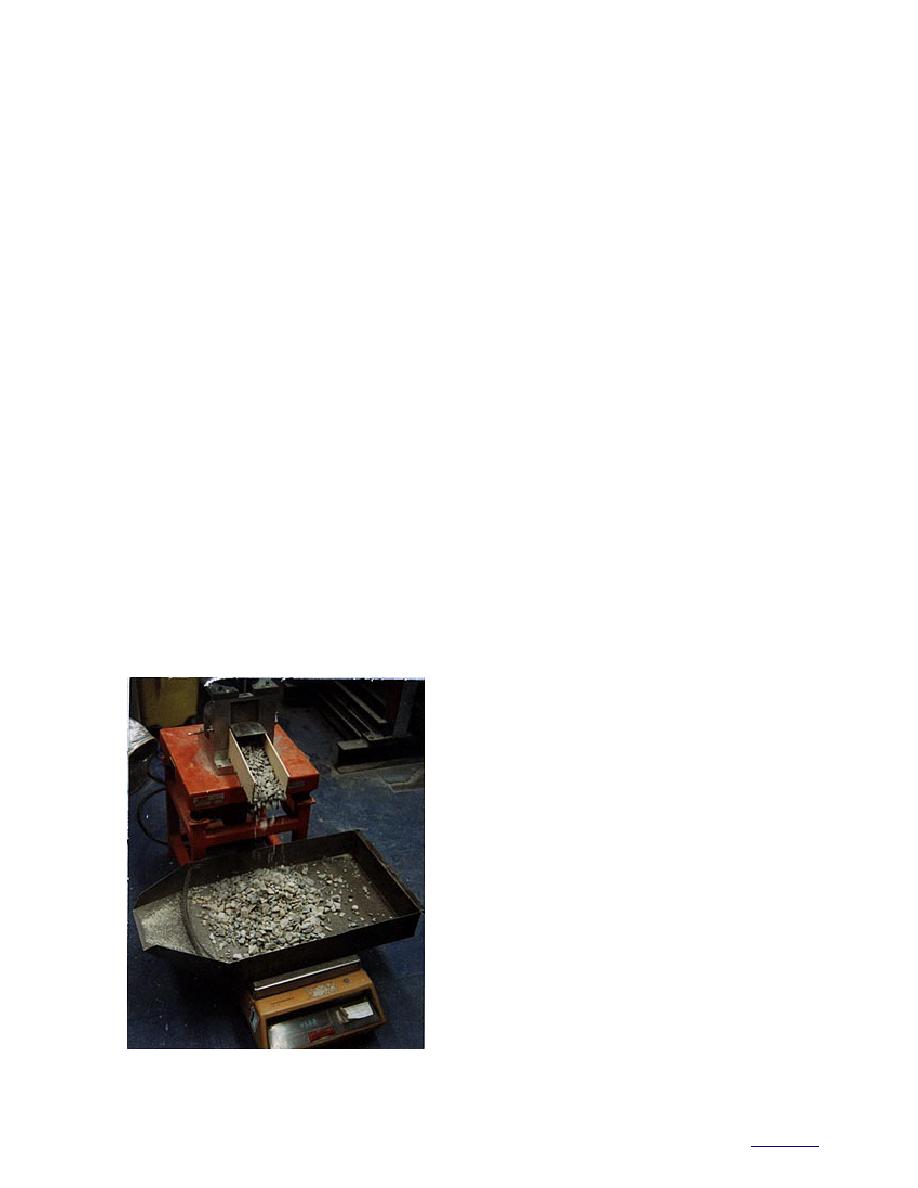

tests, a test method developed by the Quebec

PARAMETERS INFLUENCING

Ministry of Transportation characterizes the angu-

SKID RESISTANCE

larity and surface texture of aggregates using the

For HMA pavements, skid resistance depends

rate of flow of the aggregate through a known-

diameter opening (Fig. 12). Additional details on

on the friction developed between the pavement

this apparatus can be found in Janoo (1998).

surface and the tire. This friction is dependent on

The index, the flow coefficient (Ce), is a func-

the microscopic and macroscopic roughness of the

tion of the time it takes 7 kg of material to move

pavement surface, the polishwear characteristics

through a 60-mm-diameter opening for material

of the aggregates, and the ability of the surface to

passing the 20-mm sieve and retained on the

drain (Beaton 1976). Marek (1972) reported that

4-mm sieve. A different size is used for the fine

50% of the initial skid resistance is lost during the

aggregates. In addition, the flow coefficient

first two years of pavement service and that the

depends on the bulk specific gravity. Based on

single most important factor that affects the reduc-

tion of skid resistance is the polishing characteris-

tics of the aggregates in an HMA mix. Other fac-

tors that affect the skid resistance of the pavement

surface are wetness of the surface, seasonal varia-

tion, and temperature.

The skid resistance of a wide range of dry sur-

faces is high and fairly constant. When these sur-

faces get wet, however, the skid resistance drops

and is very dependent on the surface type. There

is seasonal variation: the skid resistance is higher

on wet roads during the winter than in the sum-

mer (Hosking and Woodford 1976) because in

winter the road surface is contaminated by sand-

ing and salting and the removal of fine material

increases the roughness of the microtexture. In the

summer, continuous abrasion of the macrotexture

produces fines that coat the microtexture and

reduce the skid resistance.

The friction of the surface is indexed from field

tests following various standardized tests (ASTM

E 274 [1994] and E 1551[1994]). The procedure is

based on measurements of the frictional force

developed between a standard tire at a standard

Figure 12. QMOT time index test apparatus.

inflation pressure and the wetted pavement sur-

9

to contents

Previous Page

Previous Page