25

a.

b.

Soprema

WR Grace

20

CRREL

15

CRREL

10

Supplier

5

Supplier

0

25

c.

d.

Polyguard

Protecto Wrap

20

CRREL

15

CRREL

10

Supplier

Supplier

5

0

25

e.

f.

NEI

Royston

20

15

CRREL

10

CRREL

5

Supplier

0

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

Displacement (in.)

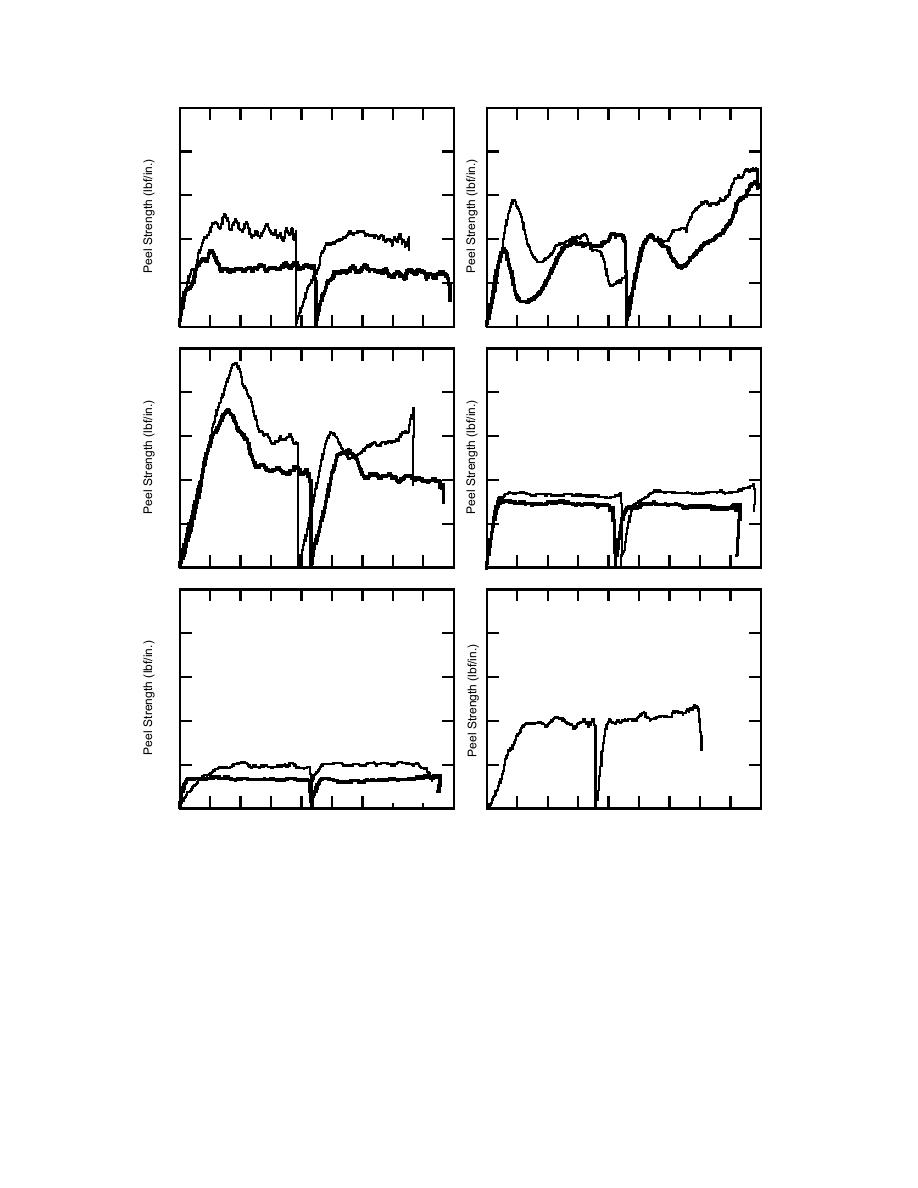

Figure 4. Adhesion test results. Each curve is the average of up to 15 test strips. Surprisingly, the CRREL

samples consistently developed high overall, but low individual, adhesion values (Fig. 4 vs. App. B).

Here, the Protecto Wrap and W.R. Grace mem-

provide a consistent adhesion in the field from job

branes become the membranes with the least po-

to job and contractor to contractor.

tential problems. They exhibit moderate, but very

uniform, adhesion values with little indication of

TENSILE STRENGTH AND ELONGATION

weak spots (Fig. 4a and 4d). Interestingly, the

Protecto Wrap membrane seemed the least influ-

Waterproofing membranes must be able to span

enced by the source of the samples for testing. This

active cracks in a deck, especially at low tempera-

uniformity suggests that this membrane would

tures, when cracks widen most. To do this, a mem-

7

Previous Page

Previous Page