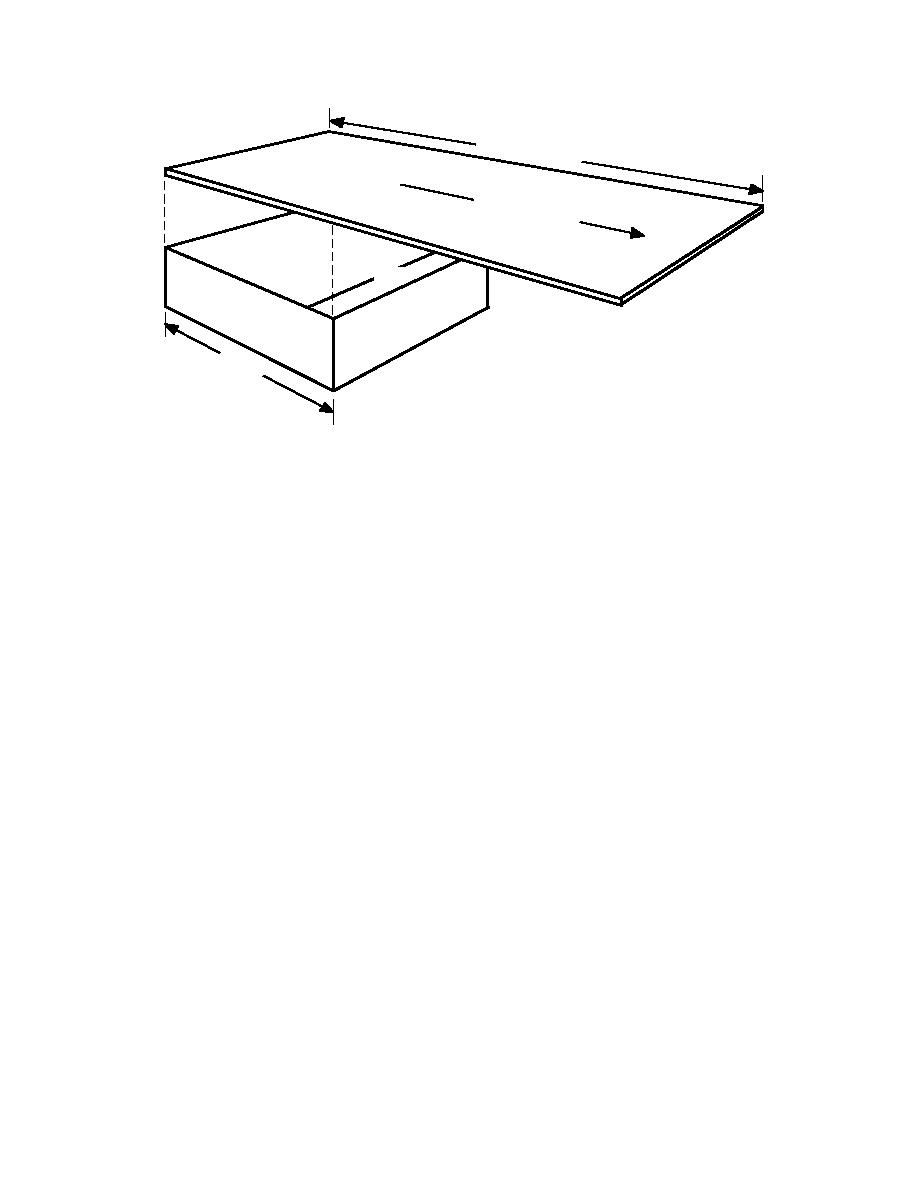

2X Len

gth + 1

in.

Layin

gD

irectio

n

Bond Area

Tape

Le

ng

th

Figure 1. Fabrication of test specimens.

Cut beams into 6- 6.38-in. (15.2- 16.2-cm)

Blister mechanics

slices.

In a related study, Korhonen (1986) pointed out

Sand slices (slabs) with 24-grit silicon-carbide

that roof membrane blisters develop from voids

sandpaper until surface is flat and all saw marks

built into a roof during construction. There is no

are removed.

reason to suspect that bridge blisters are any dif-

Oven dry the mortar slabs at 220F (104C) for

ferent. They probably are caused by the expansion

24 hours.

of air pockets inadvertently trapped between the

Clean sanded surface with dry, stiff fiber bristle

membrane and the concrete deck during construc-

brush.

tion. Roughness of the concrete deck, unevenly

Place 0.75-in. wide strip of tape across one end

applied or inadequately cured primer, debris, and

of slab.

moisture are among a number of reasons that can

Apply primer to the test surface.

impair the adhesion of a membrane to a deck and

Allow primer to cure to a tack-free finish.

lead to blister-causing voids. On the other hand, a

Apply membrane according to manufacturers'

perfectly adhered membrane (if it exists) cannot

instructions.

blister.

Condition specimens at approximately 70F

Fortunately, a membrane does not have to be

(21C) and 50% RH (relative humidity) for a

perfectly adhered to a deck. Mathematically, it can

minimum of 14 days.

be shown that some voids are acceptable. When

Cut membrane into five 1-in.- (2.5-cm) wide

blisters form, they appear as slightly bloated

strips through to the mortar with a sharp razor

humps--in the membrane or the overlying pave-

knife.

ment--several inches to a foot or two in diameter.

Start cuts 0.50-in. (1.3 cm) from edge of slab.

They often occur soon after the membrane is laid

or immediately after hot-mix pavement is placed

Figure 2 shows the test setup. Five strips of

on top of the membrane. As eq 1 shows, growth

membrane were peeled off each slab back at an

happens only when the air inside a void is heated

angle of 180 at a grip separation rate of 4 in. (10.2

sufficiently to push the overburden upward and

cm)/min. Force and grip displacement were re-

peel it off the deck:

corded for each strip. Slippage in the grips and

membrane stretching are discounted, grip dis-

F = (PA WA)/L

(1)

placement is exactly twice membrane displace-

ment. Before discussing the significance of the ad-

hesion test data, we will first consider the

where F = membrane-to-deck peel strength

mechanics of blistering.

P = internal pressure

3

Previous Page

Previous Page