Table 3. Coarse aggregate gradation. The

13.2- and 9.5-mm headings indicate the

nominal size of the gradation.

Table 4. Fine aggregate.

Percent passing

CRREL

CRREL

Percent passing

Denver Part I & II

Part II

Denver

CRREL

Sieve size

Mix 10 (13.2 mm) (9.5 mm)

Sieve size

Mix 10 Part I & II

9.5 mm

--

--

--

9.5 mm

100

100

38.1 mm

100

100

100

4.75 mm

100

100

26.5 mm

100

100

100

2.36 mm

91

89

19.0 mm

75

100

100

1.18 mm

66

66.3

600 m

13.2 mm

38

69.8

100

38

41.5

300 m

9.5 mm

4

37.3

93.6

16

8.6

150 m

4.75 mm

1

3.2

17

5

6.5

75 m

2.26 mm

0.6

--

--

2.4

3.3

75 m

0.2

--

--

Specific gravity

2.638

2.67

Specific gravity

2.724

2.89

2.89

Absorption

1.1%

1.1%

Absorption

0.76%

0.52%

0.52%

specimens were periodically removed from the

Measurements

oven, sealed in plastic bags until the moisture

The relation between dielectric constant and

evenly distributed itself in the specimens, meas-

water content was developed by taking a TDR

ured with the TDR system, and weighed. (See

reading each time a specimen was dried a small

Results for a description of how drying times

amount. The initial TDR readings were taken

were determined and of how an even moisture

when the specimens were removed from the cur-

ing water and their surfaces were towel-dried to

distribution was determined.) The weights were

saturated surface-dry (ssd) conditions. At that

converted into moisture contents after the speci-

mens reached a constant weight in the 105C

point the specimens were also weighed. The

oven.

specimens, along with the embedded TDR

probes and coaxial cables, were then placed into a

60C drying oven, being careful not to kink the

RESULTS

cables. The specimens were dried at 60C, for all

but the final drying, to prevent any possibility of

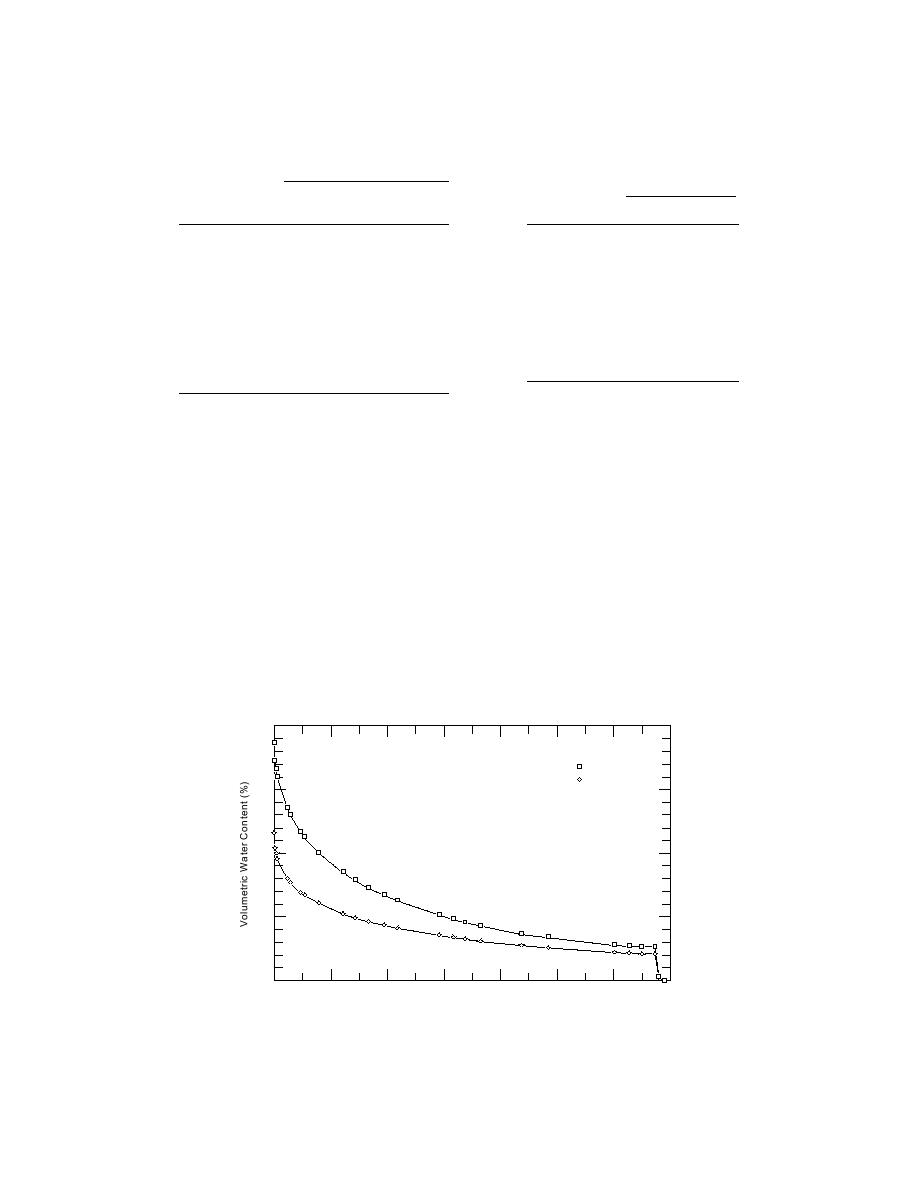

Figure 2 presents the drying curves for dum-

melting the coaxial cable. The final drying was

my specimens of concrete and mortar. As previ-

conducted at 105C. During the 60C drying, the

ously mentioned, the specimens instrumented

20

Mortar

Concrete

15

10

5

0

0

100

200

300

400

500

600

700

Drying Time (hr)

Figure 2. Drying curves for 76- 152-mm mortar and concrete cylin-

ders at 60C. The oven-dry condition (final data point) was achieved by

drying the cylinders at 105C.

4

Previous Page

Previous Page