cylinders in three equal lifts and was consolidat-

Freezing strength

ed using a vibration table. This method of cylin-

Objective

der consolidation overcame many of the difficul-

Mortar is most susceptible to frost damage at

ties of dealing with the different moisture levels

early age because: a) its pore structure is under-

between the mortar batches. Once consolidated,

developed, and b) its moisture content is high.

the filled cylinder molds were capped with plas-

Based on these two conditions, two experiments

tic lids and placed into a 20C (4F) room over-

were devised to establish thresholds of when

night. The next morning the cylinders were

mortar can withstand one cycle of freezing and

moved into a 20C (68F) room. After 28 days, not

thawing. The objective was to determine these

including the time in the cold room, the mortar

thresholds in terms of moisture content or in

cylinders were stripped from the plastic molds

terms of maturity.

and tested for compressive strength. Control cyl-

inders from each batch that were not subjected to

Critical moisture

freezing temperatures were tested at an equiva-

As stated above, the moisture content of mor-

lent age.

tar is a critical factor during early-age freezing.

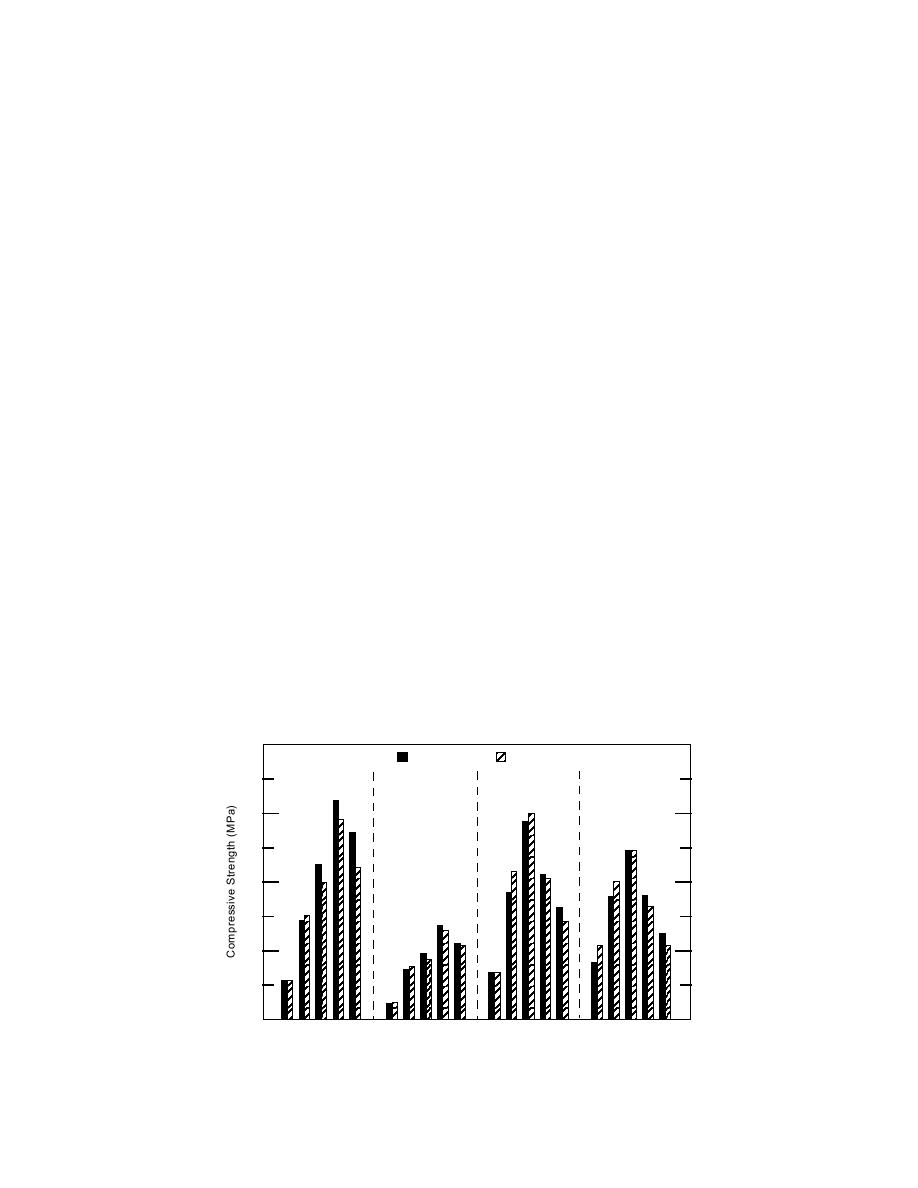

Figure 11 presents the compressive strength

Mortar is typically mixed to a moisture content of

test results from the four mortars made with five

between 13 to 16%, but due to evaporation, ab-

different moisture contents. As can be seen, all

sorption into masonry units, and cement hydra-

mortars were unaffected by being frozen at mois-

tion, its moisture content declines. Current guid-

ture contents of 6 and 8%, and each had a 28-day

ance is based on the premise that mortars that are

strength that was equal to or greater than that of

frozen while they contain more than 6% moisture

the control mortar. In fact, the mortars performed

will be frost damaged and subsequently never

better, compared with the control, when frozen at

develop full strength. Conversely, it is believed

8% moisture contents than when frozen at 6%.

that mortars with moisture contents below 6% are

The effects of frost damage started to become evi-

frost resistant. This section evaluated the effect of

dent at a moisture content of 10%. At that level,

freezing on fresh mortar in an attempt to identify

the portland cementlime mortars suffered a 9 to

the maximum moisture content that mortar may

12% loss of strength, but the masonry cement

have and still be immune to one event of freezing.

mortars were largely unaffected. (Microscopic ex-

The four mortar types described earlier were

amination showed the masonry cement mortars

made into several batches, each containing a dif-

contained entrained air bubbles. The portland

ferent moisture content. Once mixed, the mortars

cementlime mortars did not contain entrained

were cast into 50- 100-mm (2- 4-in.) plastic cyl-

air.) At moisture contents of 12% and above, all

indrical molds. The mortar was placed into the

mortars showed some, though not significant,

40

No Freeze

Freeze

Portland

Portland

Masonry

Masonry

Cement/LimeM

Cement/LimeN

CementM

CementN

30

20

10

0

6 8 10 12 14

6 8 10 12 14

6 8 10 12 14

6 8 10 12 14

% Moisture

Figure 11. Critical moisture.

12

Previous Page

Previous Page