our knowledge of the mechanisms of freezing

were planned to define the parameters that deter-

and the moisture regime of typical masonry built

mine whether a newly placed masonry system

in cold weather. The field application demon-

will be harmed by cold weather. The active ingre-

strated the use of antifreeze admixtures in winter

dient in the mechanism of frost damage is water.

masonry construction.

Therefore, the experimental work followed the

moisture content of mortar and masonry units

from the mixing operation to the masonry assem-

LABORATORY EXPERIMENTS

bly stage through the curing period. The experi-

ments also evaluated the practicality of using

Absorption

antifreeze admixtures, originally designed for

Objective

cold-weather concrete, in masonry mortars. The

Dry mortar is immune to frost damage; water-

final objective was to transfer findings through re-

saturated mortar is susceptible to frost damage.

ports, conference papers, and updates to masonry

At the time of placing, mortar is water saturated,

construction manuals.

and therefore frost susceptible. To define the tran-

sition between susceptibility and immunity, three

Approach

fundamental parameters needed to be defined: a)

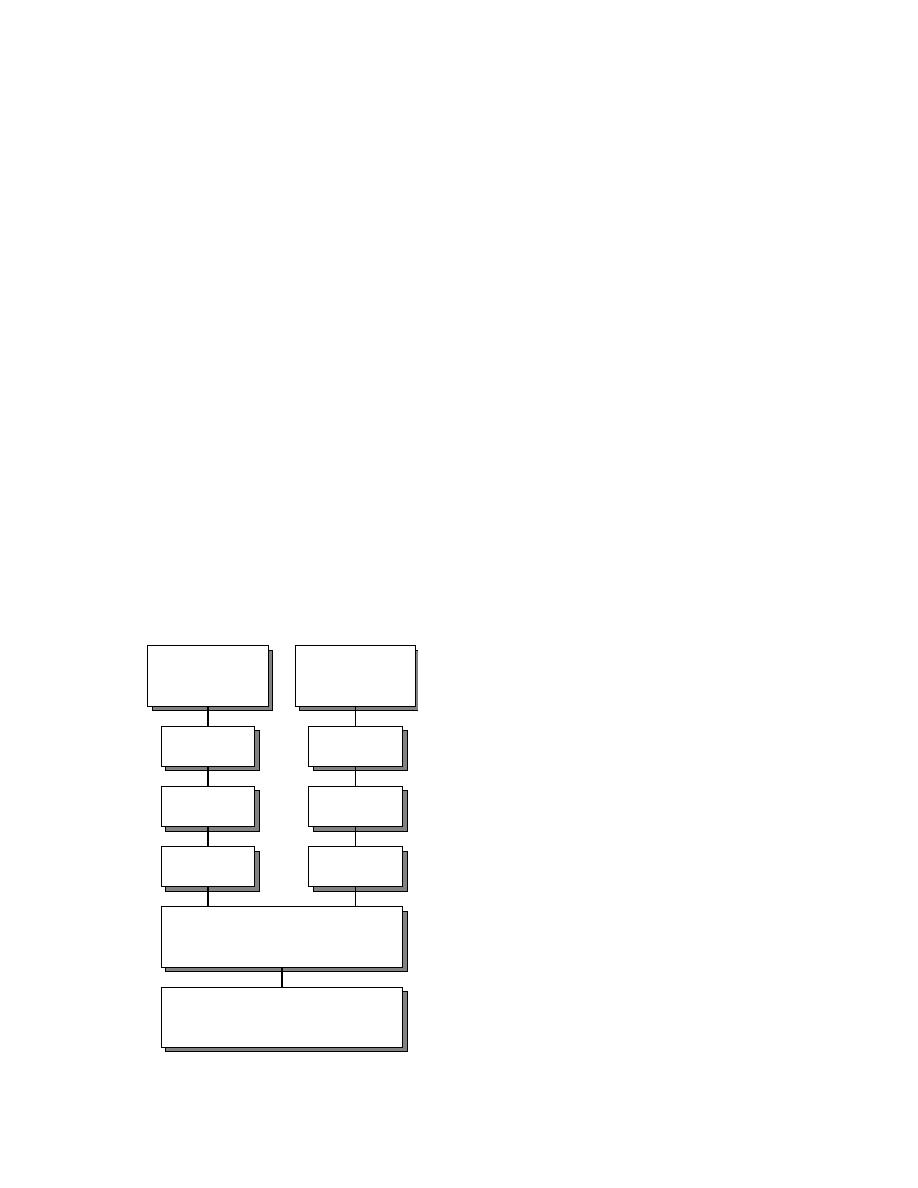

The experimental work in this project consist-

the maximum water content that mortar can have

ed of two major stages: a series of laboratory

without frost damage, b) the time needed for

experiments, and a field application. As shown in

mortar to dry to any given moisture content, and

Figure 1, the laboratory experiments were divided

c) the major factors that determine the rate of

into two sections. Section 1 evaluated the effect of

mortar moisture loss. One of these factors is the

low temperatures on conventional masonry, and

absorption of mortar moisture by the masonry

section 2 evaluated the usefulness of antifreeze

units. The objective of this section of the report is

admixtures. The laboratory experiments were a

to develop correlations of mortar moisture con-

series of tests, each designed to produce informa-

tent versus time for mortar placed between typi-

tion useful to better define the minimum thermal

cal masonry units.

protection requirements for cold weather

masonry construction. The test results enhanced

Mortar types and mixture proportions

ASTM C 270 lists four types of mortar (M, S, N,

and O) specified under each of two types of ce-

Section 1

Section 2

ment blending methods: on-the-job blending of

Conventional

Antifreeze

portland cement and lime (PCL), and factory pre-

Masonry

Admixtures

blended masonry cement (MC). Two mortar mix

design methods are in common use: the propor-

tion method and the property method. The

Compressive

Absorption

Strength

proportion method specifies certain volumes of

portland cement, hydrated lime, and sand to be

mixed with water to achieve a certain degree of

Freezing

Bond

workability. Alternatively, prebagged masonry

Strength

Strength

cement (MC) can be used together with sand and

water to achieve the same effect. The property

method allows for the use of alternative volume

Durability

Durability

combinations, provided laboratory test mortar

achieves the prescribed values for strength, water

retention, and air content. The proportion meth-

Field

od was used for the mortar mix designs of this

Demonstration

project.

Hydration and strength development rates are

reduced as ambient temperatures drop. Gener-

ally, no specific rules are given for selecting a

Technology

Transfer

mortar type for use at low temperatures. How-

ever, it is acknowledged that higher portland

cement contents promote higher strengths at low

Figure 1. Research plan.

temperatures compared with similar mortars

2

Previous Page

Previous Page