mounted parallelogram ripper on this tractor.

Horizontal force should also be similar when con-

sidering either a front- or rear-mounted tool, both

having similar configurations.

EXCAVATING HARD

AND FROZEN GROUND

A variety of hard ground conditions cause prob-

lems for conventional, unassisted dozers. These

commonly include frozen ground, dense over-

consolidated sediments, weak rock, coral, and

desert caliche. Seasonally frozen ground causes

significant problems because it is very common

and because freezing greatly increases the strength

of the ground surface, often preventing penetra-

tion with conventional tools. Seasonal frost is

widespread in the Northern Hemisphere, and can

be several feet thick. The southern limit of sub-

stantial frost penetration, where frost depth is

about 12 in. (30.5 cm) once in every 10 years, is

shown in Figure 4 (Bates and Bilello 1966); how-

ever, south of this limit seasonal frost can be thick

enough to frequently hinder excavation.

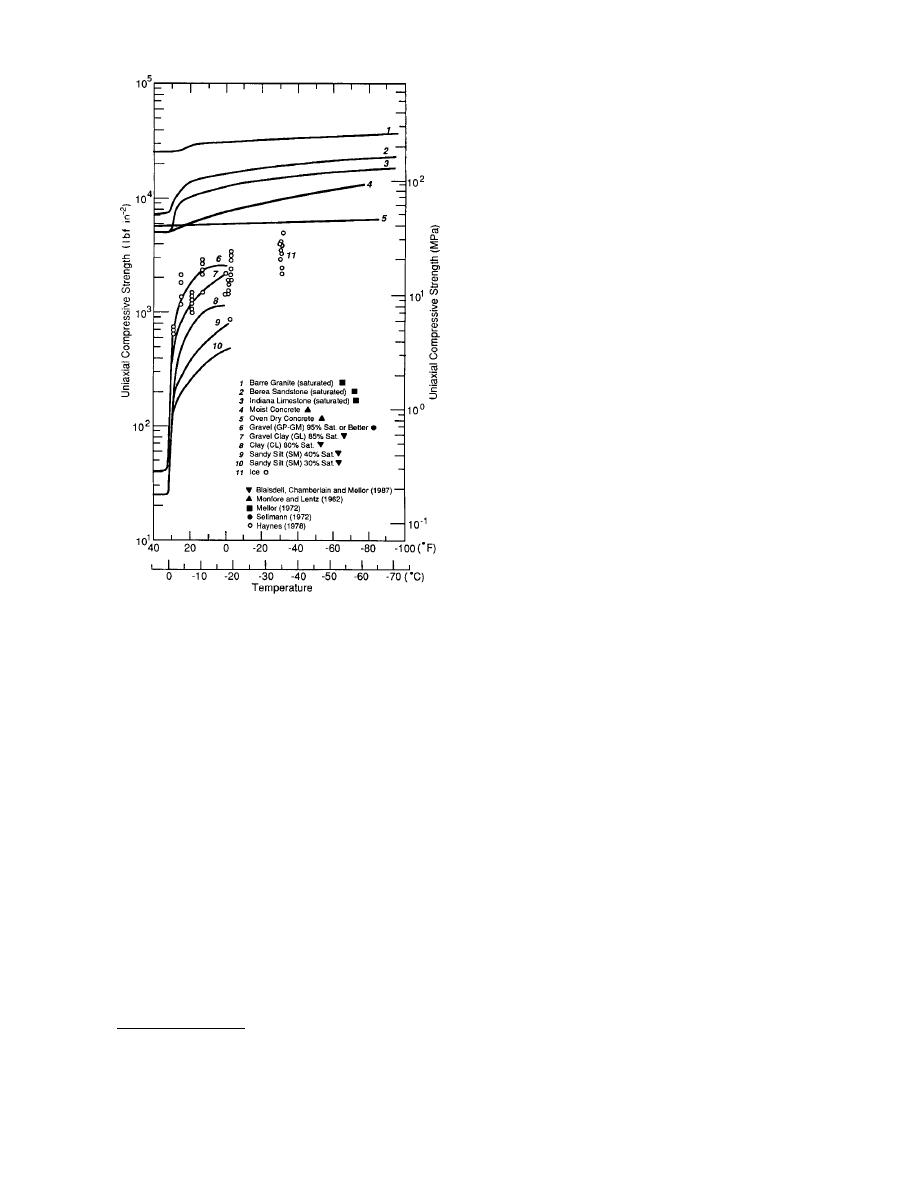

Soil and rock significantly increase in strength

with freezing (Fig. 5), with more than an order of

magnitude increase common for most soils

(Sellmann 1989). The strength of frozen soils con-

tinues to increase with cooling at temperatures

Figure 5. Effect of freezing and subsequent cooling on

normally encountered during winter. Frozen soils'

the unconfined compressive strength of concrete and

strengths can approach those of unfrozen chemi-

earth materials: soil, rock, and ice (from Sellmann

1989).

cally bonded materials, such as weak rock and

concrete. Therefore, excavation problems are

caused by even thin layers of frozen ground.

about 170 to 870 lb (77 to 395 kg). The smallest

Soil strength depends on several factors, in-

model has 11 in. (28 cm) of penetration and, for

cluding moisture content, grain size, and ground

our observations, was attached to the blade of a

temperature. For purposes of excavation, frozen

John Deere 550 dozer.

soils can be grouped into two general categories

Quantitative performance information for

based on their grain size: 1) fine-grained soils that

blade-mounted rippers is not readily available,

include various mixtures of silt, clay, organic ma-

compared to the large background of experience

terial, and ice, and 2) coarse-grained soils consist-

and information on the more common rear-

ing primarily of sand and gravel, with aggregates

mounted rippers. However, if it is assumed that

ranging from small pebbles to large cobbles. Of

dozer blade penetration force and rear-mounted

these the frozen fine-grained soils usually are most

ripper penetration force are similar for most

easily ripped and cut, and tend to be more ductile

crawler tractors, it may then be possible to make

compared to the more brittle and abrasive coarse-

some performance predictions for the less com-

grained material. The high strength and often large

mon blade-mounted attachment. It is interesting

particle size and abrasive nature of the coarse-

to note that data for the D7H indicate that down

grained material make excavation difficult to im-

force on the cutting edge of the dozer blade is

possible for small machines. Machines that can

approximately 21,000 lbf* (93 kN), which is very

generate high tool forces, and have large teeth

close to the penetration force developed for a rear-

compared to aggregate size, have the best chance

of working the coarse material.

* Personal communication with Caterpillar, Inc., 1994.

5

Previous Page

Previous Page