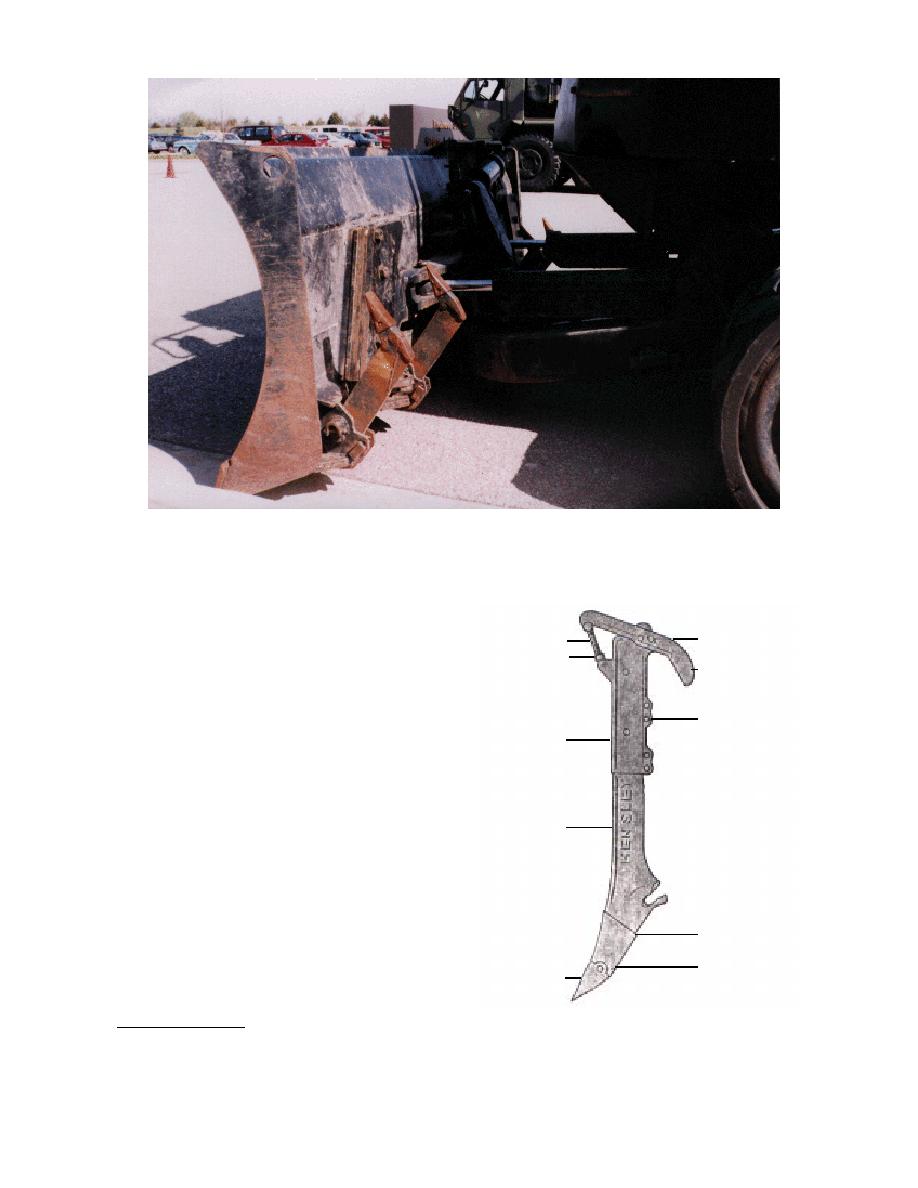

Figure 2 (cont'd).

and is used to direct the material being displaced).

The attachment was introduced around 1947* and

6" Pin with Cotter

Adjusting Bolt

is still available in several sizes for use on a large

Adjusting Nut

range of bulldozers, depending on blade size, trac-

Yoke

tor power, and weight. The length of these rip-

pers also increases with tractor size and weight,

4" Pin with Cotter

with a maximum penetration depth of 2 ft (61 cm)

Sleeve

for the largest model. Attachment is not difficult.

The top of the ripper is secured with an adjust-

able yoke that clamps at the top of the dozer

blade, and the bottom is engaged by placing the

lower part of the blade into a notch in the ripper

Shank

shank. This notch is constructed to distribute

forces to the lower part of the blade and cutting

edge. Figure 3 shows all the components of the

ripper, including the replaceable ripper tooth or

wear point. Rippers for smaller tractors can be

easily installed by two people since they can be

Wear Collar

put on one component at a time. On the smallest

model, the largest and heaviest component is the

Pin

ripper shank, which weighs 112 lb (51 kg). The

Wear Point

total weight of the Hensley rippers varies from

Figure 3. Ripper attachment for use on moldboards of

dozers (used with permission of the GH Hensley Co.).

* Personal communication with GH Hensley Co.

3

Previous Page

Previous Page