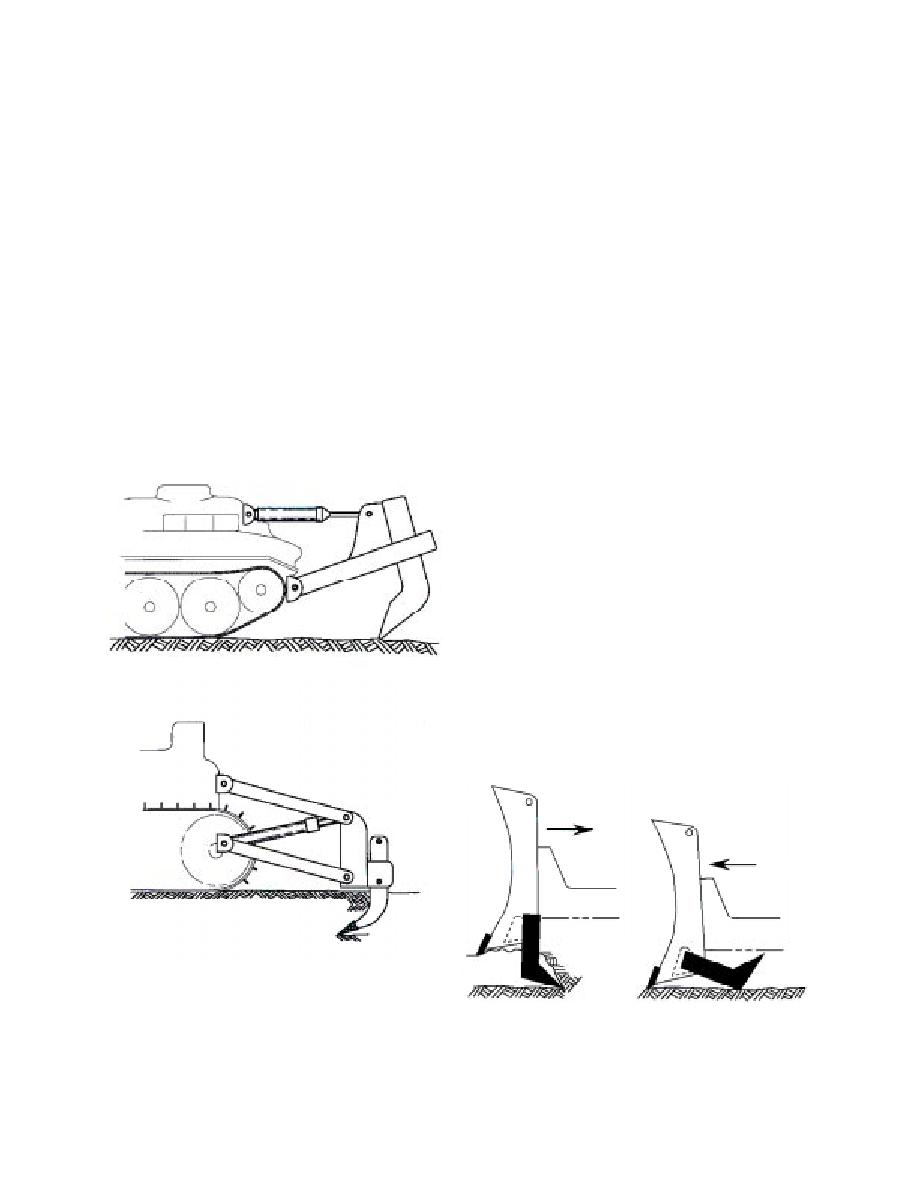

on the Russian T-34 tractor. Ripper tooth angles

TRACTOR-MOUNTED RIPPERS

change with depth with the radial system. The

parallelogram attachment (Fig. 1b) has the ad-

Rear-mounted rippers

vantage of maintaining the same ripper angle at

Crawler tractors have been fitted with a vari-

all depth settings. A single ripper is usually used

ety of ripping schemes, as mentioned in the fol-

to concentrate forces when ripping is difficult or

lowing discussion. Rear-mounted rippers are of-

when deep penetration is needed. Multiple rip-

ten fitted on modern crawler tractors and are

per arrangements are often used on large tractors

specifically designed by the manufacturer to

and when ripping is less difficult. Increased pro-

match machine characteristics. They are made for

ductivity and performance in hard ground and

a large range of tractor sizes with various ripper

rock is possible with new hybrid rippers that cre-

configurations and linkage designs for depth con-

ate high ripping forces at the ripper tooth using a

trol and adjustment. This type of ripper provides

hydraulically powered impact system.

the greatest penetration and highest productiv-

ity. Penetration depth using rippers on very large

machines can be as great as 4 to 5 ft (1.2 to 1.5 m)

Dozer back-rippers

Back-rippers are attached to the rear of a dozer

and range from 10 to 30 in. (0.25 to 0.75 m) on

machines of the D7 class and smaller.

blade in a manner that allows them to swing down

Rippers are hydraulically controlled through

into place for use when a tractor reverses. They

their linkage systems, with radial and parallelo-

rip and scarify a surface so that on a following

forward pass loosened material can be moved

gram attachments common. The radial system in

with the blade. These rippers do not interfere

Figure 1a is an idealized version of a ripper used

when dozing, since forward motion causes them

to swing to the rear from their upper connection

and drag along the ground as shown in Figure 2.

When not in use they can be moved up and se-

cured. These small blade-mounted rippers are in-

stalled on the Caterpillar DEUCE, and are also

fitted on the Army D7 bulldozer. Ripping with

this type of ripper is also discussed in FM 5-434

(U.S. Army 1992).

Removable ripper

attachment for dozers

a. Radial.

A less common commercial ripper attachment

is available for use on the moldboards of dozers

(moldboard refers to the curved metal plate that

makes up most of the blade on a dozer, snow, or

land plow; it is a continuation of the cutting edge

b. Parallelogram.

Figure 1. Idealized view of linkages commonly used for

attachment and adjustment of rear-mounted rippers.

Figure 2. Back-rippers attached to the rear of a dozer

Variants of these attachments have additional control

blade for ripping and scarifying.

for adjusting the angle of the ripper tooth.

2

Previous Page

Previous Page