U.S. Standard Sieve Numbers

Hydrometer

6" 4"

2"

1"

10

40

200

3/8"

100

0

P-306 Econocrete Subbase Course

25 mm Max.

80

20

51 mm Max.

60

40

40

60

38 mm Max.

20

80

100

0

100

10

1

0.1

0.01

0.001

Grain Size (mm)

Gravel

Sand

Cobbles

Silt or Clay

Coarse

Fine

C'rse

Medium

Fine

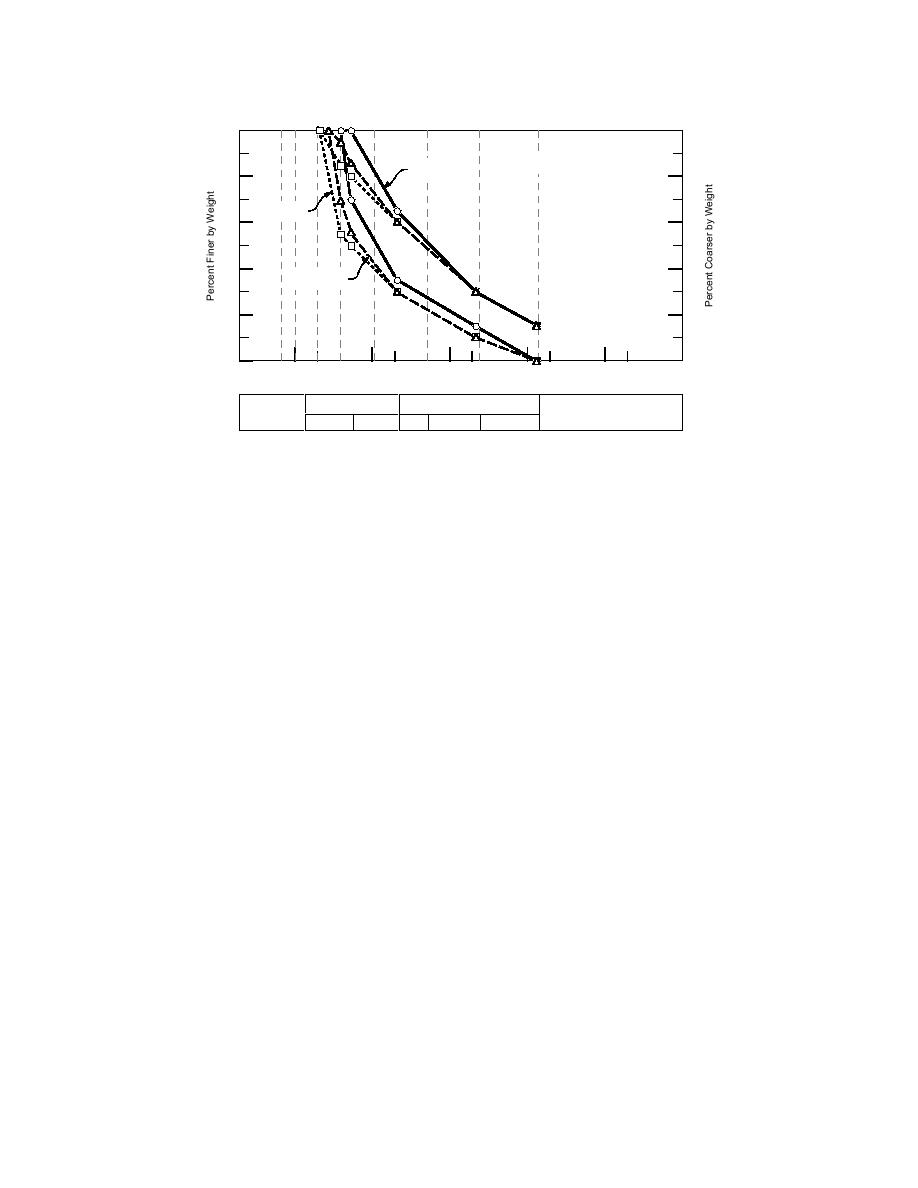

h. P-306 Econocrete subbase course.

Figure 1 (cont'd). Grain size distribution limits.

cement specified can be ASTM (1992a) C150 Types

I, II, III, IV, or V. The soil must have no more than

minute pores and the amount of fines in the base

45% retained on the no. 4 sieve. Any gravel in the

course may not be significant enough to cause

soil must be smaller than 1 in. (2.5 cm). Test speci-

water to be drawn to the freezing front.

mens should be subjected to the ASTM (1992c,

1996) D559 and D560 durability tests for wetdry

P-212 shell base course

and freezethaw strength losses. At the end of 12

P-212 shell base course is made from reason-

wetdry or freezethaw cycles, the weight loss has

ably clean oyster or clam shells. Chemically, these

to be no more than 14% for granular materials,

shells form from calcium carbonate (CaCO3) pre-

10% for granular soils with some plasticity, and 7%

cipitate. Shell base courses were used under sev-

for clay soils. The compressive strength of the sta-

eral military airfields in the Gulf coast area in the

bilized material has to increase with age and

mid- to late-1950s. The strength of this material is

cement content.

probably lower than that of caliche or lime rock.

The specified gradation limits are shown in Fig-

P-304 cement-treated base course

ure 1e.

P-304 cement-treated base course is a mixture of

cement (portland cement or bitumen), water, and

P-213 sandclay base course

mineral aggregates. The aggregates can be crushed

P-213 sandclay base course is a mixture of

or uncrushed and meet the gradation limits in Fig-

clay and mineral aggregate. The mix can be a

ure 1g. The portland cement specified can be

sandclay, sandclaygravel, disintegrated gran-

ASTM (1992 a, b) C150 Types I, II, III, IV, or V or

ite or topsoil; however, the coarse portion of this

ASTM C595 Types IS, IS-A, IP, IP-A, P, or PA.

mix has to be gravel or stone. Two gradations are

Aggregates containing any amount of sulfates that

specified (Fig. 1f) based on the PI. Gradation A

has a PI ≤ 4% and gradation B a PI ≤ 6%. The liq-

would cause expansion of the cement-treated base

course by reacting with the alkalis in the cement

uid limit for both gradations is less than or equal

should not be used, or sulfate-resistant cements

to 25%. The PI limits in this specification appear

should be specified. If bitumen is used, either cut-

to be low for the allowable amount of fines (clay)

back (RC-70 and RC-250) or emulsified (RS-1, SS-1

passing the no. 200 sieve.

or CRS-1) asphalts are specified. The liquid limit

and PI of the blended material passing the no. 40

P-301 soilcement base course

sieve has to be less than or equal to 25% and less

P-301 soilcement base course is made from a

than 6% respectively. The 7-day compressive

mixture of soil, portland cement, and water. The

6

Previous Page

Previous Page