U.S. Standard Sieve Numbers

Hydrometer

6" 4"

2"

1"

10

40

200

3/8"

100

0

P-213 Sand-Clay Base Course

80

20

60

40

Gradation A

40

60

20

80

100

0

100

10

1

0.1

0.01

0.001

Grain Size (mm)

Gravel

Sand

Cobbles

Silt or Clay

Coarse

Fine

C'rse

Medium

Fine

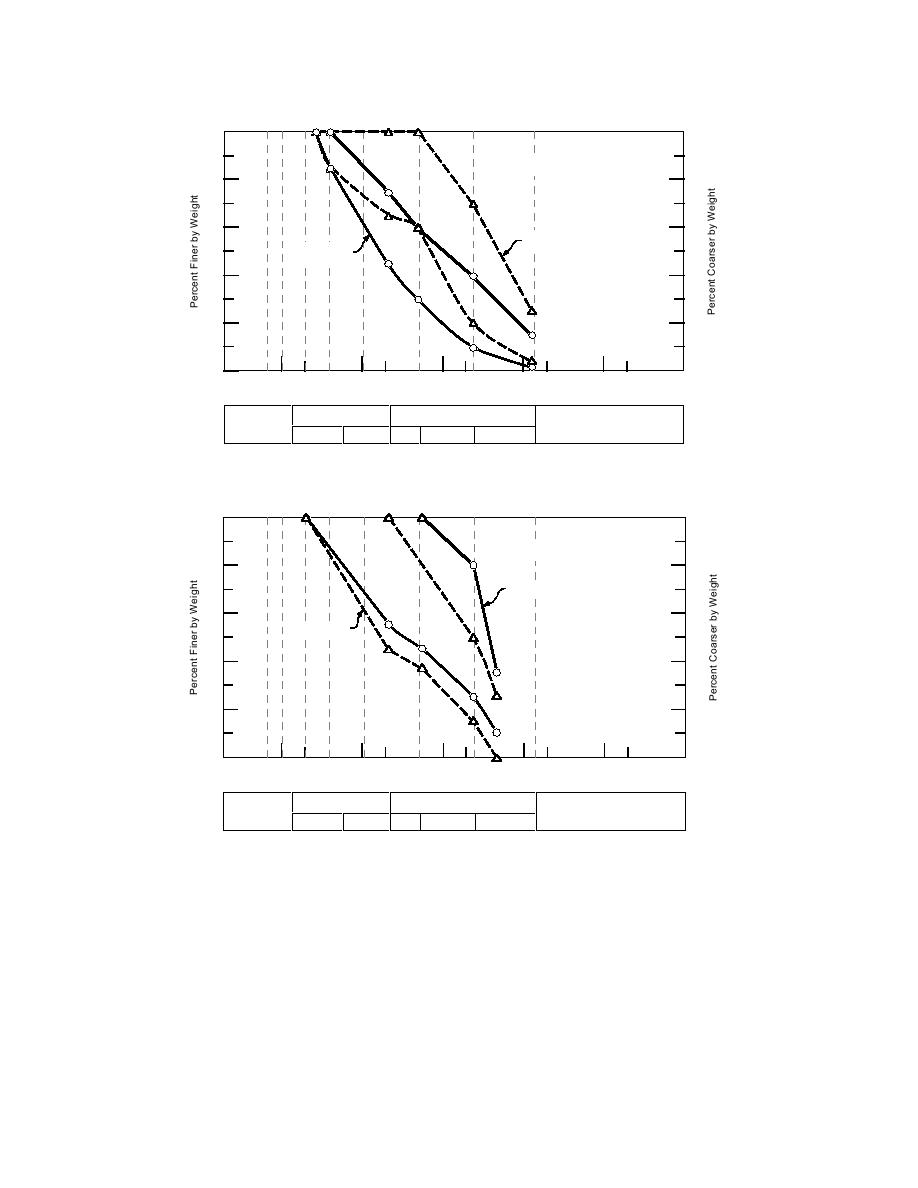

f. P-213 sand clay base course.

U.S. Standard Sieve Numbers

Hydrometer

6" 4"

2"

1"

10

40

200

3/8"

100

0

P-304 Cement Treated Base Course

80

20

60

40

Gradation A

40

60

20

80

100

0

100

10

1

0.1

0.01

0.001

Grain Size (mm)

Gravel

Sand

Cobbles

Silt or Clay

Coarse

Fine

C'rse

Medium

Fine

g. P-304 cement-treated base course.

Figure 1 (cont'd).

tendency to "air slack" or undergo chemical

and magnesium carbonates is 95%. The liquid lim-

it is less than or equal to 35% and the PI ≤ 6%. All

changes when exposed to the environment. If

oolitic (softer variety of limestone) lime rock is

fine materials used are obtained from the crushing

used, then the minimum amount of either calci-

operation. The allowable gradation is that 100%

um or magnesium carbonate present is 70%. The

passes the 90-mm (3.5-in.) sieve and 50 to 100%

amount of iron and aluminum oxide has to be less

passes the 19-mm (0.75-in.) sieve.

than 2%. The minimum combined amount of car-

Limestone is a sedimentary rock made from

bonates, oxides, and silica is 97%. This material

predominantly calcite (CaCO3). So, surface water

also has to be nonplastic. If other types of lime

entering into the base course can react with the

rock are used, the minimum amount of calcium

limestone to form a weak acid that then attacks it.

5

Previous Page

Previous Page