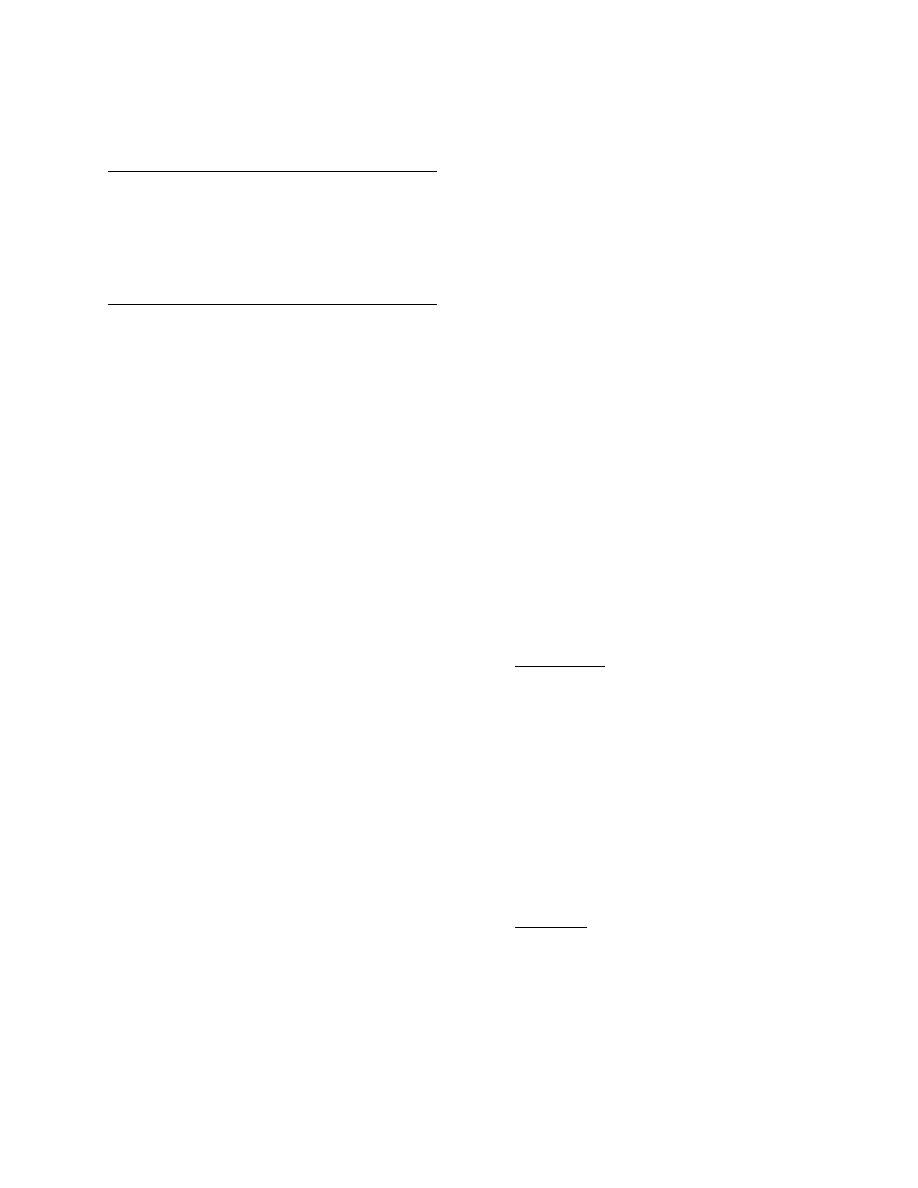

Table 6. Contribution of experimental factors to

accepted as statistically insignificant. Liquid flow

ShallowTray stripping efficiency of TCE, PCE and

rate was somewhat significant to TPH removal

TPH (% contribution as determined by analysis of

but the main controlling factor was liquid tem-

variance [ANOVA]).

perature, which contributed to 74.3% of the TPH

stripping differences observed at the six factor/

Parameter

TCE (%)

PCE (%)

TPH (%)

level combinations. The interaction of the two

Flow rate

2.8

0.0

14.9

experimental factors was insignificant and the er-

Liquid temperature

64.3

15.7

74.3

ror or unexplained variability was low (8.4%).

Interaction

The low error term indicates that all variables

(Flow temp.)

15.6

60.1

2.4

significant to TPH stripping were controlled dur-

Total error

17.3

24.2

8.4

ing the experiment.

Sampling error

3.24

4.24

10.4

Analytical error

6.56

8.86

6.3

Unexplained error*

7.5

11.1

0

Treatment process

power requirements

* Total error (sampling + analytical error) = unexplained

Total treatment costs involve many variables,

error

and the specific capital, operating and mainte-

nance costs of the batch process presented here

the compound's volatility (PCE is slightly more

would be difficult to use for predicting large scale

volatile than TCE).

or continuous flow treatment systems. However,

The VOC error terms are both >15%, indicat-

it is instructive to examine the power consumed

ing that experimental error or unexplained vari-

per volume of water treated as stripping and wa-

ability was unacceptably high. Approximately

ter heating components. Power consumption rates

45% of this unexplained variability was due to

can be compared between widely different strip-

analytical and sampling error. The mean relative

per types and treatment methods to give a rough

standard deviation (RSD) of combined analytical

economic comparison for initial design choices.

and sampling variability is 9.8% (TCE) and 13.1%

Air stripper power consumption data were

(PCE) (see Table 6). The majority of the unex-

plotted, yielding an inverse relationship between

plained variability, 55%, is due to factors that

power consumed (kW/3785 L treated) and flow

were not fully controlled during the experiments,

rate (Fig. 8). The equation describing this rela-

in particular the VOC influent concentrations. Be-

tionship is the predictor equation for stripping

cause the highly effective VOC stripping produced

(only) power requirements:

consistent effluent concentrations over a narrow

[

]

-1

kW

= 0.02 (QL ) + 0.0157

range, the wide range of influent concentrations

(9)

3785 L treated

(which were not a function of the experimental

factors but of treatment process handling) cre-

where QL = liquid flow rate (L/min).

ated a large variability in VOC removals which

was independent of the controlled variables. This

Water was heated for treatment during six tri-

"process handling" variability is particularly no-

als, each time raising a different volume from a

ticeable in the duplicate trial data. Influent VOC

different initial temperature to either 15.56C or

concentrations of the two pairs of duplicate trials

22.2C. The kilowatts (kW) required to heat the

differed from 1.136.8% RSD. Effluent concentra-

liquid (using the equipment previously described)

tion variability was even greater (20.184.1% RSD)

were recorded. When these data were plotted as

due to the extremely low concentrations that ex-

kW/C increase vs. liters of water heated, the

aggerate even the smallest of differences. The net

linear relationship was described by a first-order

result of this uncontrolled error was to make it

regression:

impossible to correlate the VOC data into a VOC

removal prediction model.

[

]

kW

= 0.0034 (VL ) - 4.035

The statistical estimate of the main effects and

(10)

C increase

factor interactions during ShallowTray stripping

of TPH was also determined by analysis of vari-

where VL = liquid volume (L)

ance (ANOVA) of removal data (R). A summary

of experimental parameter contributions to TPH

From eq 10 it can be seen that when VL = 3785 L

(1000 gal.), 8.83 kW/∆C are required. This vari-

removal is shown in the right-hand column of

Table 6. A contribution below 15% is generally

able can be added to the equation for stripping

12

Previous Page

Previous Page