Predicted TPH Removal (%)

where RP = predicted future value of R

TL = influent liquid temperature (C)

45%

QL = influent liquid flow rate (liters/

70

50

minute).

55

According to eq 8, a one-degree increase in tem-

60

perature will result in a 2.61% ( 0.25%) increase

60

in TPH removal, and a unit increase in liquid

65

50

flow rate will decrease TPH removal by 0.22%

( 0.05%). The correlation coefficient for this equa-

70

tion, r2, equals 0.972. At the low flow rate (18.9 L/

75

40

min), eq 8 predicts that 100% TPH removal will

occur at 27.0C. However, as in the case for de-

80

creasing removal vs. flow rate, removal can rea-

30

sonably be expected to reach some asymptotic max-

85

imum as temperature increases. This predicted

maximum removal temperature is in good agree-

20

ment with vapor pressure data reported in the

10

12

14

16

18

20

22

Liquid Temperature (C)

literature for diesel range hydrocarbons (decane,

C10H22, through octacosane, C28H94). Vapor

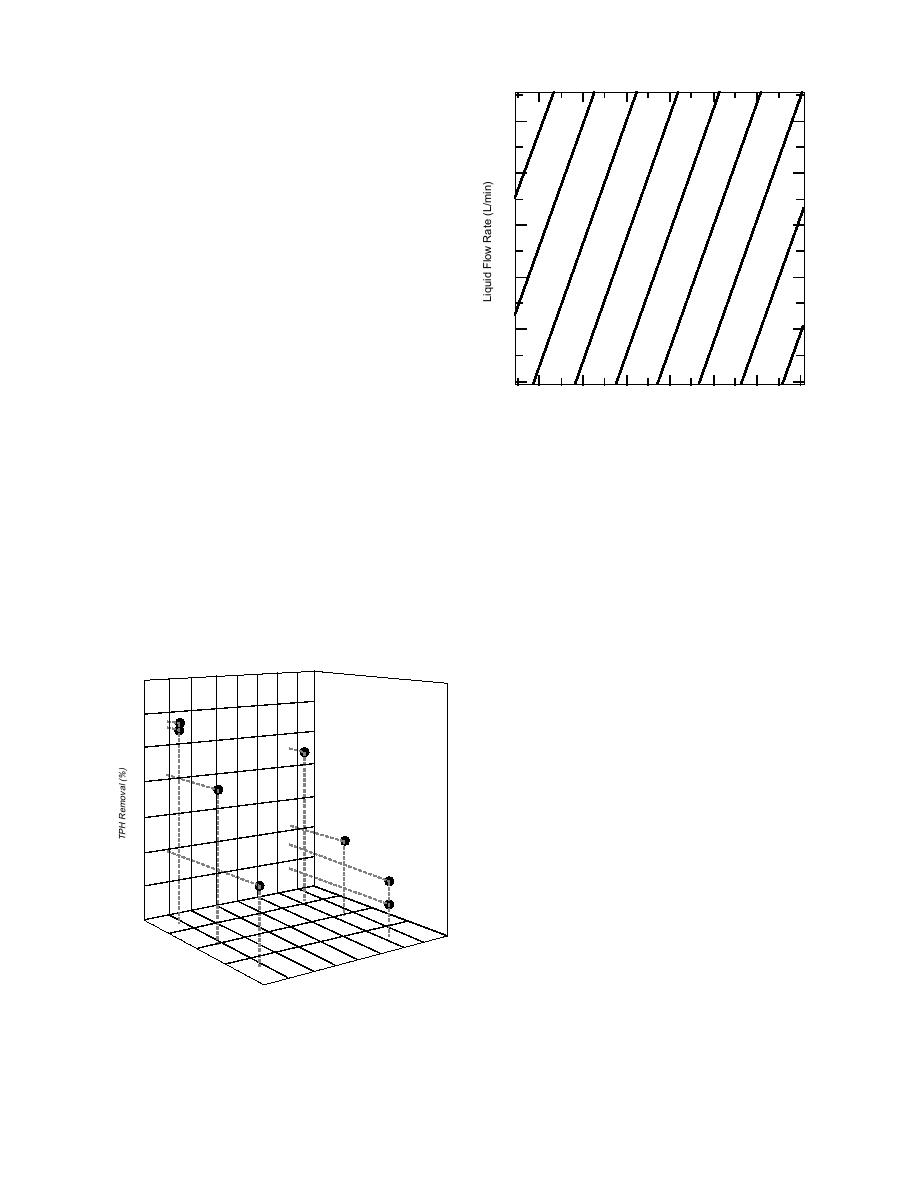

Figure 7. Predicted response surface for TPH removal

pressure of a hydrocarbon-saturated liquid was

vs. liquid temperature and flow rate.

estimated (Franks 1966) to be roughly atmo-

spheric at 25C for the C10 through C20 hydrocar-

saturated gas phase and the liquid phase contain-

bons, which make up roughly two-thirds of the

ing the highest possible concentration of soluble

diesel range. A discussion of phase equilibria in

C10 through C16 hydrocarbons is expected at at-

water-hydrocarbon systems contained in API

mospheric pressure and 25C. The model (eq 8)

(1976) refers to Franks (1966) and others in defin-

ing 25C as the "maximum temperature for the

predicts this will occur in the ShallowTray strip-

per at atmospheric pressure and 27C. Equation 8

water-rich phase" of waterhydrocarbon systems

is shown graphically as a predicted response sur-

containing diesel range paraffins (C10 through

face in Figure 7. When lines are extended from

the x and y axes at known values of liquid tem-

perature and flow rate, they will intersect nearest

to the diagonal line that predicts the percent of

100

TPH removal.

Influence of experimental factors

on ShallowTray performance

80

The statistical estimate of the main effects and

factor interactions during ShallowTray stripping

of TCE, PCE and TPH was determined by analy-

sis of variance (ANOVA) of removal data. A sum-

60

mary of experimental parameter contributions to

contaminant removal is shown in Table 6. A con-

tribution below 15% is generally accepted as sta-

40

tistically insignificant.

The ANOVA results show that liquid flow rate

25

did not affect VOC removal, but liquid tempera-

20

Liq

ture was the most significant factor influencing

uid

80

15

Te

60

mp

TCE removal and somewhat significant to PCE

)

10

/min

era

te (L

40

tur

a

ow R

e(

id Fl

removal. The interaction of the two factors was

C

20

Liqu

5

)

the dominant factor influencing PCE removal but

was only somewhat significant to TCE removal.

Figure 6. TPH stripping performance (percentage re-

The interaction and error terms also increase with

moved) at three liquid temperatures and two flow rates.

11

Previous Page

Previous Page