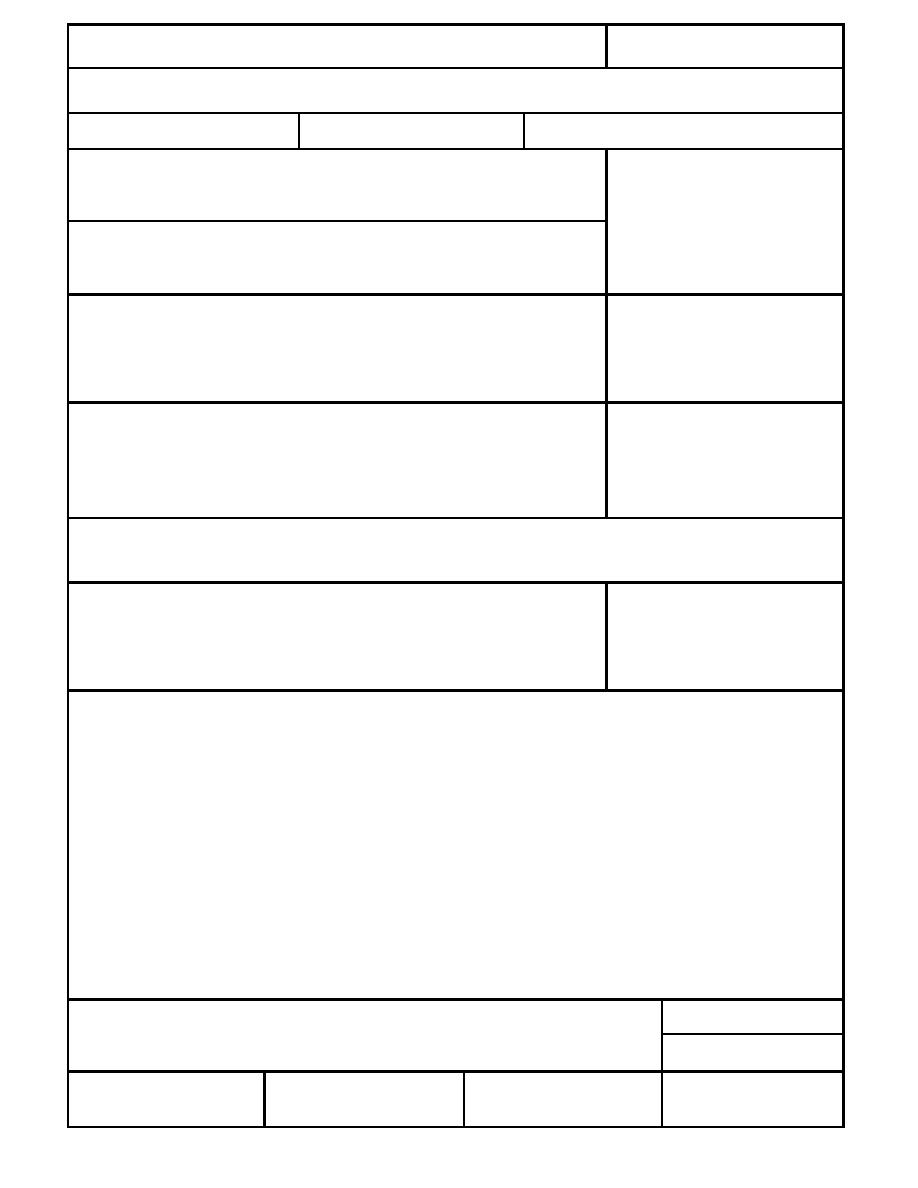

Form Approved

REPORT DOCUMENTATION PAGE

OMB No. 0704-0188

Public reporting burden for this collection of information is estimated to average 1 hour per response, including the time for reviewing instructions, searching existing data sources, gathering and

maintaining the data needed, and completing and reviewing the collection of information. Send comments regarding this burden estimate or any other aspect of this collection of information,

including suggestion for reducing this burden, to Washington Headquarters Services, Directorate for Information Operations and Reports, 1215 Jefferson Davis Highway, Suite 1204, Arlington,

VA 22202-4302, and to the Office of Management and Budget, Paperwork Reduction Project (0704-0188), Washington, DC 20503.

1. AGENCY USE ONLY (Leave blank)

2. REPORT DATE

3. REPORT TYPE AND DATES COVERED

December 1996

4. TITLE AND SUBTITLE

5. FUNDING NUMBERS

Ballistic Perforation of Graphite/Epoxy Composite

6. AUTHORS

Piyush K. Dutta, Dennis Farrell, Susan Taylor, Aziz Tadayon and David Hui

7. PERFORMING ORGANIZATION NAME(S) AND ADDRESS(ES)

8. PERFORMING ORGANIZATION

REPORT NUMBER

U.S. Army Cold Regions Research and Engineering Laboratory

72 Lyme Road

Special Report 96-29

Hanover, New Hampshire 03755-1290

9. SPONSORING/MONITORING AGENCY NAME(S) AND ADDRESS(ES)

10. SPONSORING/MONITORING

Office of the Chief of Engineers

U.S. Air Force Flight Dynamics Laboratory

AGENCY REPORT NUMBER

Washington, DC 20314-1000

Wright-Patterson Air Force Base

Ohio 45433-7542

U.S. Army Research Office

Research Triangle Park

North Carolina 27709

For conversion of SI units to non-SI units of measurement consult Standard Practice for Use of the

11. SUPPLEMENTARY NOTES

International System of Units (SI), ASTM Standard E380-93, published by the American Society for Testing and Materials, 1916

Race St., Philadelphia, Pa. 19103.

12a. DISTRIBUTION/AVAILABILITY STATEMENT

12b. DISTRIBUTION CODE

Approved for public release; distribution is unlimited.

Available from NTIS, Springfield, Virginia 22161.

13. ABSTRACT (Maximum 200 words)

This report documents the experimental details of impact studies performed on graphite/epoxy laminated plates

by spherical projectiles. The mechanism of failure and energy absorption were studied by macro- and microscopic

examination of the surfaces of the laminates. Fragments were examined under scanning electron microscope to

determine presence of any characteristic fracture surface pattern. The influence of laminate orientations was stud-

ied using unidirectional and quasi-isotropic laminates. The scanning electron microscopic examination of the frag-

ments from the impact shows that the fracture surfaces of the matrix have some characteristic hackle marks.

A discussion is provided to explain the characteristics and texture of these hackle marks and relate them to the

impact velocity, material brittleness, and energy absorption of the impact.

14. SUBJECT TERMS

15. NUMBER OF PAGES

10

Ballistic tests

Fracture

Impact

Composites

Graphite/epoxy

Micrographs

16. PRICE CODE

Dynamic fracture

High-velocity impacts

17. SECURITY CLASSIFICATION

18. SECURITY CLASSIFICATION

19. SECURITY CLASSIFICATION

20. LIMITATION OF ABSTRACT

OF REPORT

OF THIS PAGE

OF ABSTRACT

UNCLASSIFIED

UNCLASSIFIED

UNCLASSIFIED

UL

Standard Form 298 (Rev. 2-89)

NSN 7540-01-280-5500

Prescribed by ANSI Std. Z39-18

298-102

Previous Page

Previous Page