500

400

Pozzutec 20

@ 60 mL/kg

Corr.

300

Line

Reference

200

Pozzutec 20

@ 100 mL/kg

100

0

10

20

30

40

50

60

70

80

Weeks

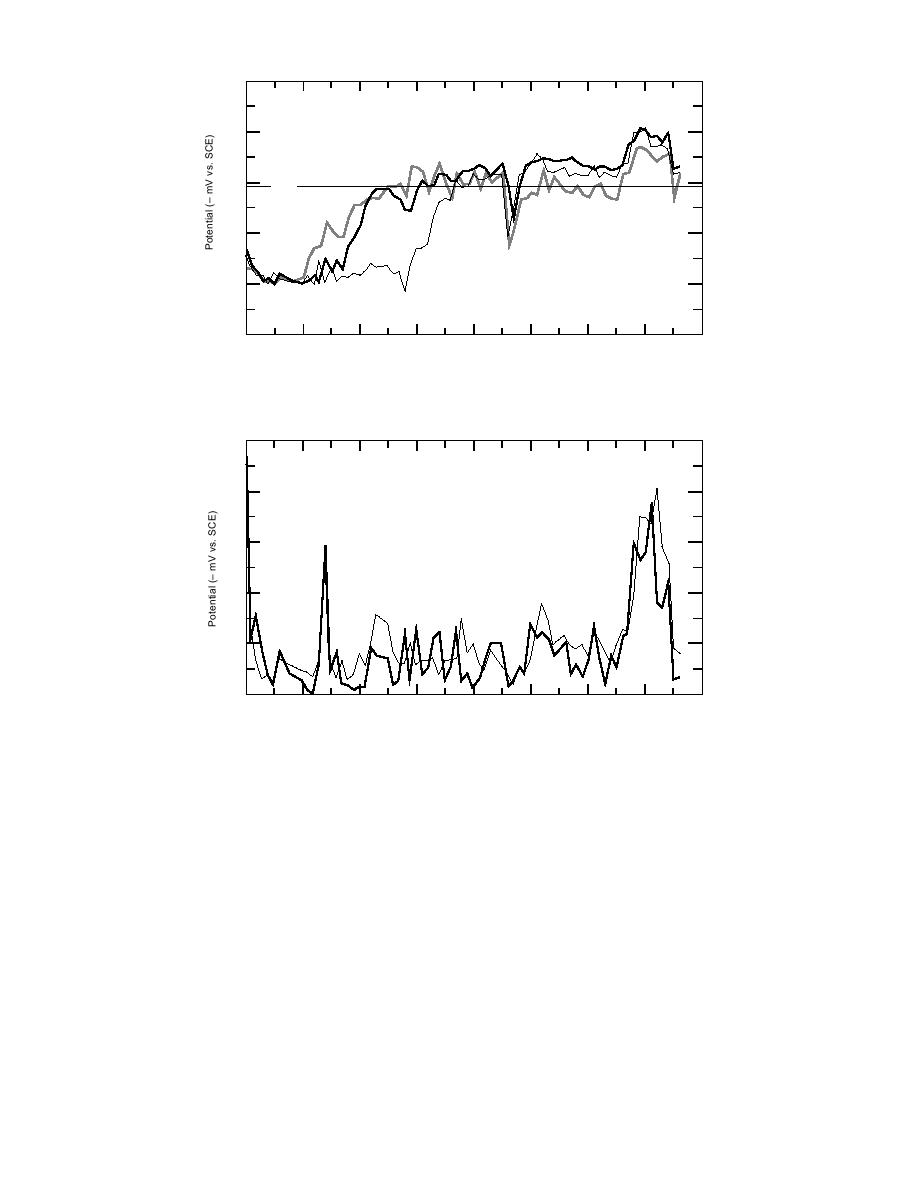

Figure 3. Lollipop specimens submerged half-height in 3% sodium chloride solu-

tion.

200

160

120

Reference

80

Pozzutec 20

@ 60 mL/kg

40

0

10

20

30

40

50

60

70

80

Weeks

Figure 4. Lollipop specimens submerged half-height in deionized water.

cured at 5C (23F) at the same rate as that in

Task 2: Corrosion potential

control concrete cured at 5C (40F). As can be

The lollipop test results show that mortars

seen, the 7-, 14-, and 28-day strengths of the high

treated with 60 mL/kg (90 fl oz/cwt) of Pozzutec

dosage concrete cured at 5C (23F) were signifi-

20 are practically identical to admixture-free mor-

cantly below that of the ACI standard for 5C

tar. Figures 3 and 4 are graphs of the average

(40F) concrete. Strength gain at 10 and 20C

potentials from three specimens over a 1 1/2-year

(14 and 4F) was even lower (see Fig. 2). This

period. There is no exact potential identifying the

does not necessarily mean that the Pozzutec con-

initiation of corrosion. ASTM C 876 identifies po-

crete has been damaged by freezing, as this con-

tentials more positive than 200 mV vs. copper

crete displayed a remarkable recovery in strength

sulfate reference electrodes as passive or noncor-

by 56 days when brought back to room tempera-

rosive behavior. Potentials between 200 and

ture. It does suggest, however, that a new admix-

350 mV are an indication that corrosion has initi-

ture would have to be developed to fully satisfy

ated, and potentials more negative than 350 mV

the low-temperature goal of this project.

indicate a high probability of corrosion. Since our

8

Previous Page

Previous Page