g/L. Currently, the EPA has not set an MCL for

tions of samples exposed to PVC, PTFE, or FEP

casings. However, after 40 days' exposure, con-

silver in drinking water. However, a previous MCL

centrations of samples exposed to FEP casings

value given in the EPA's Interim Primary Drink-

were significantly higher than the controls. Gen-

ing Water Standards (Federal Register 1975) was

50 g/L, and the values observed in this study

erally, concentrations of Ni in samples exposed to

the two fiberglass materials were significantly

are well below this value. Again, there are no data

greater than the other three materials. Mean nor-

available for these four analytes that would allow

malized concentrations for samples exposed to

comparisons to be made with SS casings.

these two materials ranged from approximately 2

to 3.5 times the control values (Table 4). However,

SORPTION STUDY

these elevated Ni levels may be the result of an

experimental artifact rather than constituents

Initial concentrations were 51 g/L for As, Cr,

leaching from the casing material. Nickel electro-

and Pb and 20 g/L for Cd.

plate was used to bind the diamonds to the steel

band that was used to cut these two materials.

Anions

The other materials were cut with a steel slotting

saw, which did not have diamonds bonded to it.

Arsenic

Even for the samples with the highest concen-

There was no significant loss of As in any of

trations of Ni, leached concentrations were less

the samples exposed to the casing materials

than 3 g/L, well below the MCL of 100 g/L set

(Table 5, Table A1). Since arsenic exists as nega-

by the EPA for drinking water (US EPA 1994).

tively charged arsenates or arsenites under the

No comparison can be made with the SS cas-

oxidizing to slightly reducing conditions found

ings, because Hewitt's (1989) study, which was

in natural waters (Fowler et al. 1979), these re-

conducted under similar conditions, did not test

sults agree with several previous studies (Masse

for Ni. Under anoxic conditions, however, Hewitt

et al. 1981, Parker et al. 1990, Hewitt 1992) that

(1992) found that SS 304 and 316 casings leached

have shown that anions do not strongly associate

consistently higher concentrations of Ni than any

with polymeric surfaces. In comparison, data from

of the casings we tested in this study. Means for

samples exposed to SS 316 were the highest and

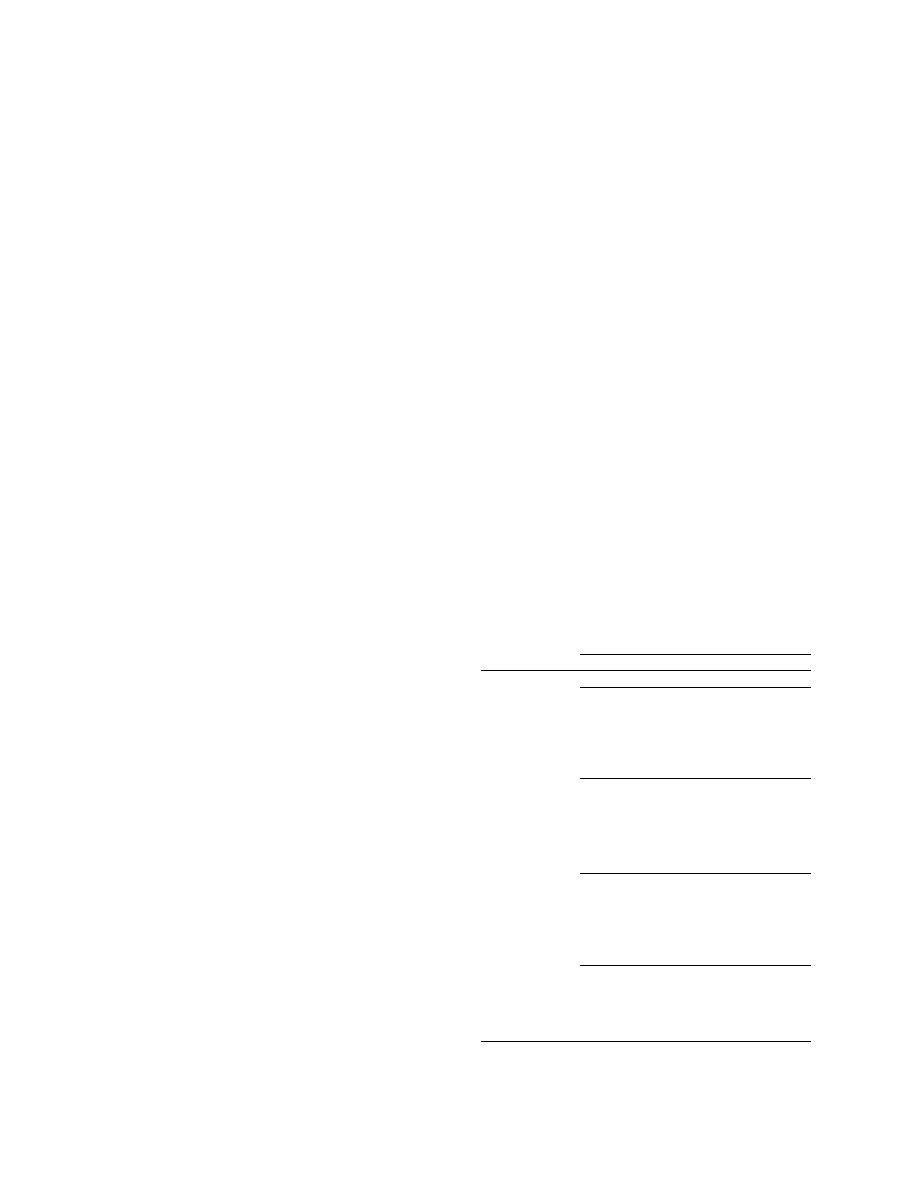

Table 5. Mean normalized concentrations of As,

were 4 to 5 times higher than the concentrations

Cd, Cr, and Pb sorbed by well casings.

of samples exposed to the fiberglass casings.

Contact time, hours

Zinc

Treatment

1

8

24

72

After one day of exposure, all the samples ex-

ARSENIC

posed to the well casings had significantly higher

PVC

1.02

1.01

1.01

1.00

PTFE

0.99

1.01

1.00

0.99

concentrations of Zn than the control samples

FEP

0.99

1.00

1.01

1.00

(Table 3g, Table 4). Concentrations in samples ex-

FRE

0.99

0.99

0.99

0.99

posed to the FRP casings were significantly high-

FRP

1.01

1.00

1.00

1.00

er than those in samples exposed to the other cas-

CADMIUM

ings; mean normalized concentrations were

PVC

0.93

0.87

0.83

0.79

approximately 7 to 12 times control values.

PTFE

0.97

0.95

0.93

0.99

FEP

0.98

0.96

0.95

0.98

Leached concentrations cannot be compared with

FRE

0.95

0.91

0.89

0.94

any MCL standard for Zn because the US EPA

FRP

0.96

0.96

0.90

0.94

has not set one. Also, no comparisons can be made

with the SS casings because there are no data avail-

PVC

1.01

1.01

1.00

0.99

able.

PTFE

1.00

1.00

1.00

0.99

FEP

1.00

1.00

1.01

1.00

FRE

0.95

0.98

0.99

0.98

Arsenic, beryllium,

FRP

1.01

1.03

1.00

1.00

selenium, and silver

LEAD

Concentrations of As, Be, and Se were all be-

PVC

0.90

0.70

0.61

0.56

low the MDL. The majority of the values for Ag

PTFE

0.98

0.95

0.94

0.93

were also below the MDL, and do not show any

FEP

0.97

0.95

0.93

0.93

apparent pattern or trend (Table 3h). In all cases,

FRE

0.89

0.65

0.55

0.45

FRP

0.91

0.71

0.59

0.52

leached concentrations of Ag were less than 0.80

9

Previous Page

Previous Page