electrical power of ice does not exceed 4 mV/C (Bry-

controlled within 0.2C. All ice samples were ma-

ant and Fletcher 1965), this effect is always small.

chined with a cutter to an outer diameter of 10 cm and

Takahashi (1969a) measured the electrical potential

then subsequently polished with sandpaper. The ice

difference between a vibrating metal plate and the sur-

and 107 Ω-1m1 at T = 10C. The measurements of

face of pure single crystals of ice, both before and after

σs were made both with the apparatus at rest and dur-

the ice was rubbed with another single crystal or with

ing experiments. No difference was found among σs

a plane. He found changes in the potential difference

ranging up to 0.20.3 V after the rubbing. Unfortunately,

values measured before, during and after the friction

he did not realize that he simply produced an icemetal

experiments. This showed that possible local melting

contact potential or, in other words, he measured a dif-

and refreezing of the ice surface does not significantly

ference in electron work functions between the metal

change the ice conductivity. When the cylinder rotated,

a frictional force changed the belt tension (T2 T1).

plate and the ice. The observed relaxation time was

very long (hours at 10C) and had nothing in common

with the dielectric relaxation time in ice, which is 5

T - T

105 seconds at that temperature. The effect that Taka-

1

=

arcth 2 1

(1)

α

T1 + T2

hashi found is likely ascribable to a difference in the

structure and thickness of the surface charge double

where α is an angle shown in Figure 1.

layer on fresh and aged ice surfaces. The layer slowly

changed by adsorption of impurities from the air and

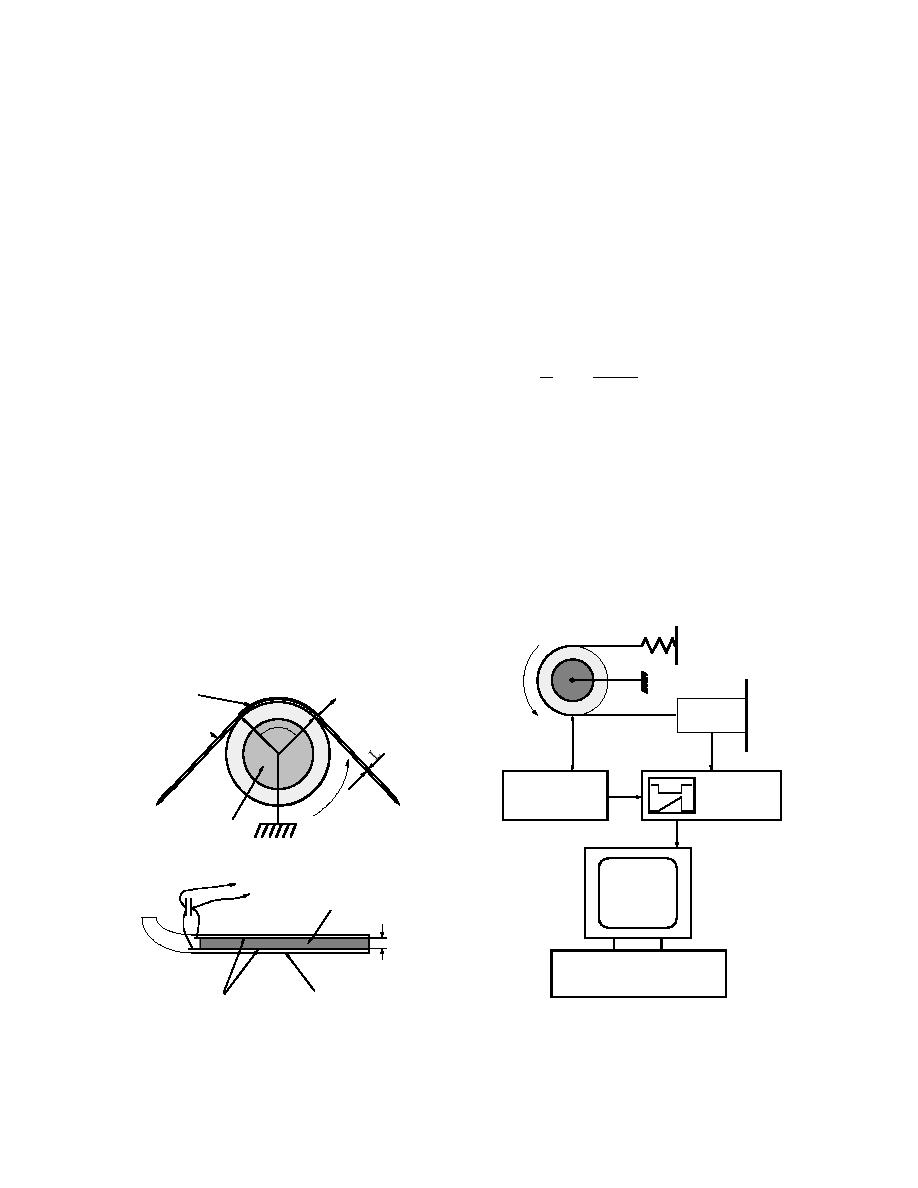

A schematic of the experimental setup is shown in

diffusion of the impurities in ice. We will discuss such

Figure 2. Reverse rotation of the cylinder allowed us to

measure T2 instead of T1. Polyethylene, aluminum and

an electric double layer in the next section.

stainless steel belts of 2.5-cm width were used as the

sliders, and measurements were made at temperatures

Frictional electrification

from 5 to 35C and at sliding velocities from 0.5 to 8

This writer (Petrenko and Colbeck 1995) studied

frictional electrification on cylindrical samples of

m/s.

polycrystalline ice grown from very pure, deionized

To determine whether friction causes melting, a

and degassed water. A polycrystalline ice layer, of

thin thermocouple (0.1 mm) was attached to the outer

about 2 cm thickness and a typical grain size of 512

mm, was frozen onto the outside of a stainless steel

spring

cylinder (Fig. 1). The cylinder was mounted on a lathe

T2

located inside a coldroom where temperature could be

to an electrometer

metal foil

T1

Ice

Load cell

dielectric film

α

Electrometer

Digital storage

ice

T1

Keithley 616

T2

stainless steel

cylinder

Electric ground

to the data logger

C(2F)

13-mm-thick dielectric plate

d

Computer

1-mm plastic plate

metal plates

Figure 2. Experimental setup (after Petrenko

Figure 1. Ice friction and ice electrification meas-

and Colbeck 1994).

urements in the laboratory (top) and on snow in

the field (bottom) (after Petrenko and Colbeck

1994).

3

Previous Page

Previous Page