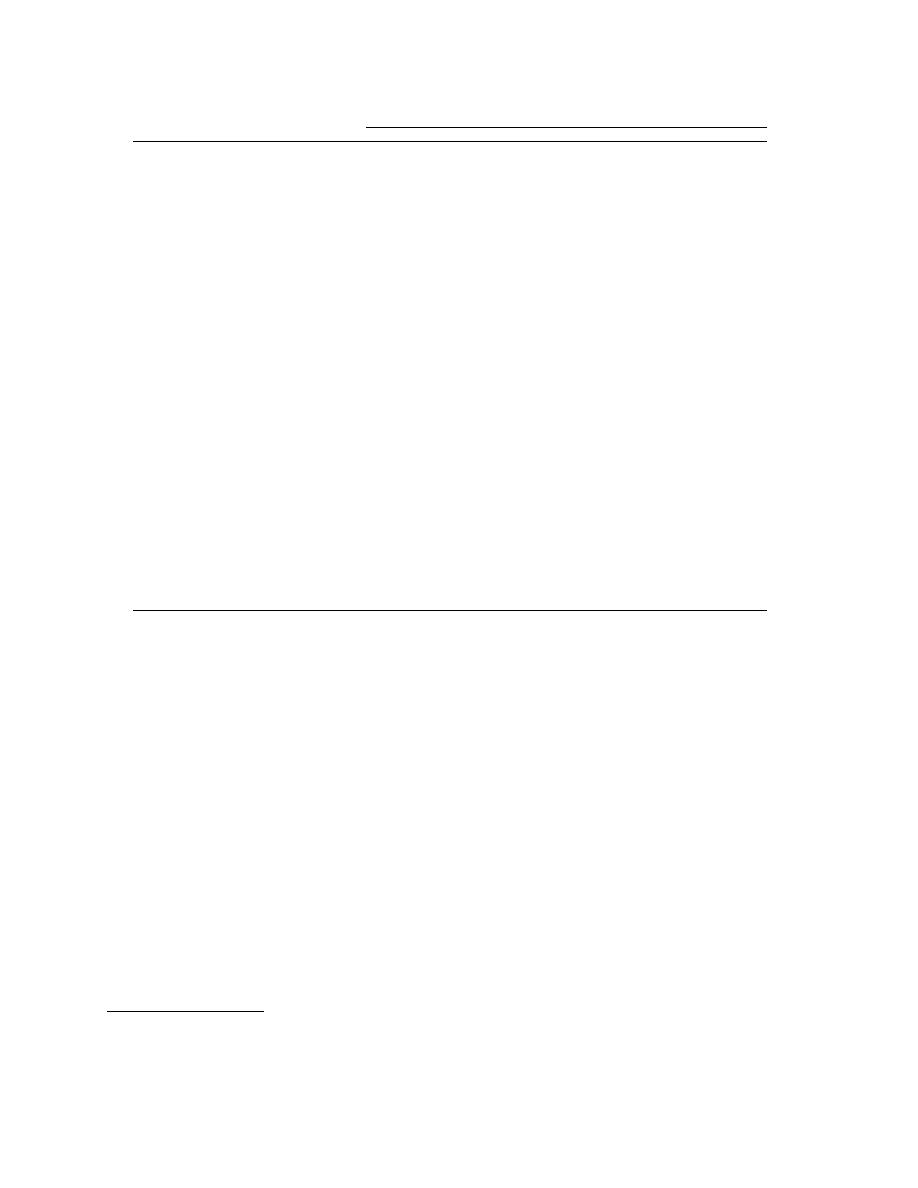

Table 6. Percentage weight gain of PVC exposed to chemical treatment.

Contact time (days)

Chemical

1

7

14

21

28

56

112

Acetic acid (glacial)

0.1

0.1

0.2

0.2

0.3

0.2

0.4

142.6s

Acetone

145.5

146.7

151.4

156.4

157.3

157.8

100.9s

Benzaldehyde

D

29.7s

Benzene

7.2

45.4

49.5

49.2

48.8

48.7

Benzyl alcohol

0.0

0.0

0.1

0.1

0.1

0.1

0.1

Bromochloromethane

D

63.8s

N-butylamine

111.0

110.7

D

Carbon tetrachloride

0.0

0.1

0.0

0.1

0.1

0.1

0.1

57.2s

Chlorobenzene

151.1

153.0

156.6

157.3

158.8

159.8

144.2s

Chloroform

216.1

218.2

221.9

220.3

222.8

223.9

Cyclohexanone

D

16.8s

1,2-dichlorobenzene

73.5

134.3

206.6

208.6

214.5

217.7

206.6s

1,2-dichloroethane

352.4

D

49.6s

trans-1,2-dichloroethylene

57.7

57.5

56.2

56.2

56.0

56.3

31.8s

Diethylamine

2.5

8.7

13.8

17.2

20.4

23.9

Dimethylformamide

D

Gasoline (93 octane, unleaded)

0.0

0.0

0.2

0.0

0.0

0.0

0.1

Hexane (85% N-hexane)

0.0

0.0

0.0

0.1

0.1

0.1

0.1

Hydrochloric acid (25% w/v)

0.2

0.2

0.1

0.1

0.0

0.1

0.3

Kerosene (K-1)

0.1

0.1

0.0

0.0

0.0

0.0

0.0

Methyl alcohol

0.4

0.1

0.2

0.2

0.2

0.3

0.4

298.9s

Methyl ethyl ketone

D

454.9s

Methylene chloride

D

138.1s

Nitrobenzene

D

Sodium hydroxide (25% w/v)

0.0

0.0

0.1

0.2

0.1

0.1

0.1

Tetrachloroethylene

0.1

0.4

0.6

0.7

0.8

1.2

1.7

Tetrahydrofuran

D

38.4s

Toluene

10.5

51.6

50.9

50.7

50.6

51.4

34.9s

Trichloroethylene

71.3

72.8

70.1

71.0

70.5

70.9

11.7s

o-xylene

3.8

17.1

23.0

28.2

44.4

65.7

D dissolved or disintegrated upon handling

s first observation of swelling and/or softening

ratings given by Cole-Parmer and Nalge compa-

ABS was by far the most readily degraded

nies, we developed the following classification

polymer. After only one day, nineteen of the

scheme for our data:

thirty chemicals tested either dissolved ABS or

A. Excellent. Any chemical that had little or no

softened it to the point where it fell apart (Table

effect on the material, i.e., where the change in

7). Four other chemicals caused either softening

weight was 1% or less.

or swelling of the test coupon on the first day. By

the end of the study, only the acid and alkali solu-

B. Good. Any chemical that had only a minor

tions had little effect (~1% weight gain). While

effect, i.e., there was no observable effect except

for a slight change in weight (from 1 to 5%).

ABS is susceptible to organic solvents in general,

C. Moderate effect. Those chemicals that caused

it is especially susceptible to polar solvents.*

more than a 5% change in weight with no other

Clearly, ABS is a poor choice where exposure to

observable changes.

neat organic solvents may be involved.

D. Unacceptable. Any chemical that caused the

Table 8 compares the chemical resistance rat-

material to swell, soften, dissolve, delaminate, or

ings from the Cole-Parmer catalog and the Nalge

that caused particles to fall off.

catalog with our (CRREL) findings. In order to

While we realize that our rating system was

compare our results with the chemical resistance

totally arbitrary, we generally had good agree-

ment between our results and those given in the

Cole-Parmer catalog. This was especially true for

* Personal communication, Daniel C. Leggett, Research

PTFE and ABS. For these materials there were

Chemist, CRREL, 1994.

7

Previous Page

Previous Page