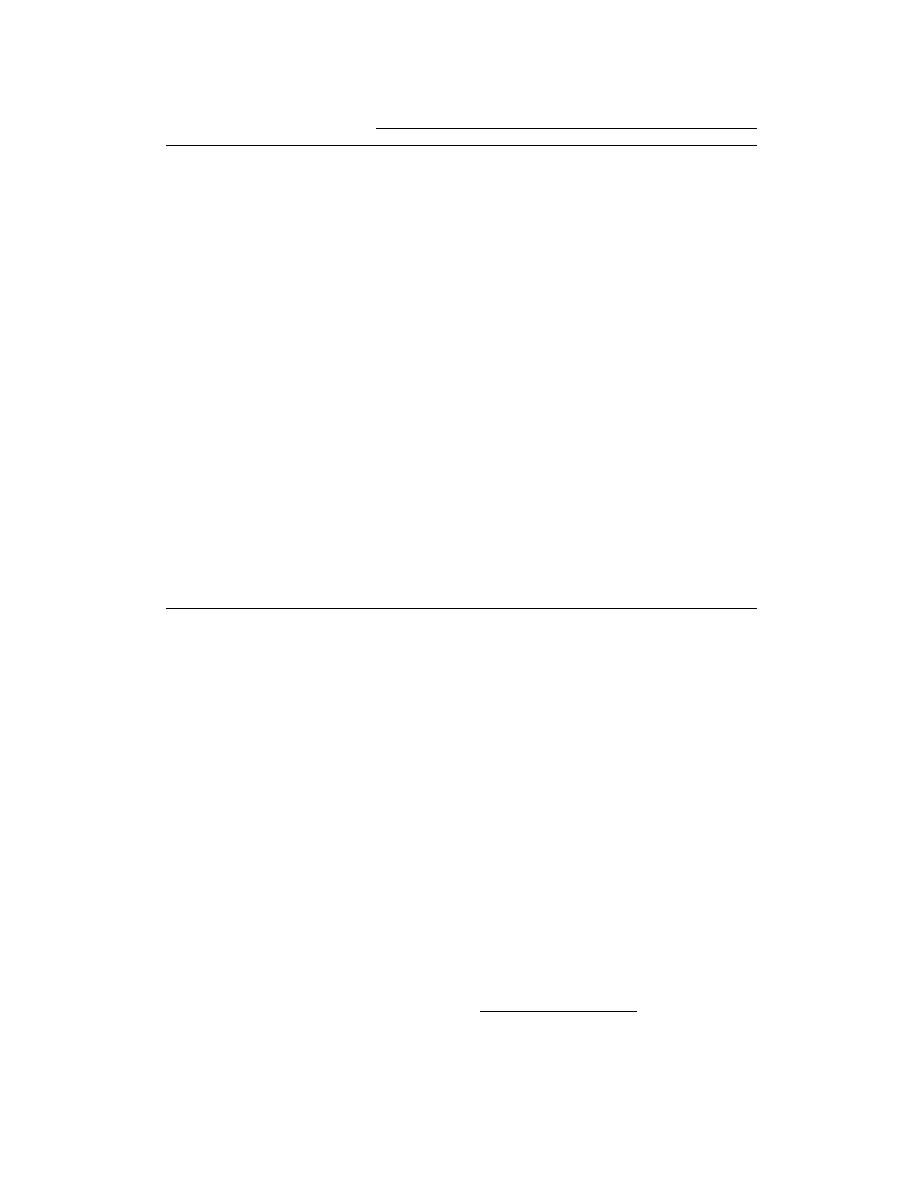

Table 5. Percentage weight gain of FRP exposed to chemical treatment.

Contact time (days)

Chemical

1

7

14

21

28

56

112

Acetic acid (glacial)

0.3

0.2

0.3

0.6

0.7

0.9

1.5

Acetone

0.2

2.5

5.0

5.5

5.6

5.6

5.6

Benzaldehyde

0.5

0.5

0.8

0.7

0.7

0.8

1.3

Benzene

0.0

0.1

0.2

0.2

0.3

0.4

0.8

Benzyl alcohol

0.4

0.3

0.5

0.3

0.4

0.4

0.5

Bromochloromethane

21.2

L

N-butylamine

0.2

0.3

1.3

L

Carbon tetrachloride

0.1

0.1

0.1

0.2

0.1

0.1

0.2

Chlorobenzene

0.7

0.8

1.5

2.1

2.8

4.5

7.8

Chloroform

6.5

L

Cyclohexanone

0.2

0.2

1.1

0.3

0.6

0.5

0.1

1,2-dichlorobenzene

0.6

0.7

0.7

0.8

0.8

1.0

1.1

1,2-dichloroethane

1.0

14.0

14.6

L

trans-1,2-dichloroethylene

7.6

11.2

L

Diethylamine

0.0

0.1

0.4

0.4

0.8

1.9

3.5

Dimethylformamide

0.3

1.1

2.3

4.4

6.2

8.7

8.3

Gasoline (93 octane, unleaded)

0.1

0.1

0.2

0.2

0.1

0.1

0.1

Hexane (85% N-hexane)

0.0

0.0

0.0

0.0

0.0

0.0

0.0

Hydrochloric acid (25% w/v)

0.1

0.1

0.2

0.4

0.7

1.8

5.0

Kerosene (K-1)

0.1

0.2

0.2

0.2

0.2

0.2

0.2

Methyl alcohol

0.2

0.6

0.9

0.9

1.1

1.5

1.9

Methyl ethyl ketone

0.1

1.5

3.6

4.6

4.9

4.8

4.8

Methylene chloride

L

Nitrobenzene

0.7

0.9

0.8

0.7

0.7

0.8

1.0

Sodium hydroxide (25% w/v)

0.0

0.1

0.1

0.2

0.2

0.4

1.5

Tetrachloroethylene

0.1

0.2

0.3

0.2

0.3

0.4

0.5

Tetrahydrofuran

0.3

2.5

6.9

9.9

L

Toluene

0.1

0.2

0.2

0.3

0.3

0.5

0.9

Trichloroethylene

0.8

7.9

16.7

16.3

L

o-xylene

0.0

0.1

0.1

0.0

0.1

0.2

0.2

glass fiber sheets separated

L

PVC appeared to be much more readily de-

dichloroethane, trans-1,2-dichloroethylene, meth-

graded than the previous materials. By the end of

ylene chloride, tetrahydrofuran, and trichloro-

the study, ten chemicals dissolved or so softened

ethylene) delaminated it, i.e., the fiberglass sheets

PVC that the test piece could not be weighed be-

separated. This occurred within the first 24 hours

cause it disintegrated (Table 6). Four chemicals

for methylene chloride and within the first one to

had this effect within the first day. Ten other

four weeks for the other solvents. The samples

chemicals appeared to soften PVC and four of

that were delaminated more slowly had weight

those chemicals caused weight gains that ex-

gains of ~1 to 16% and showed signs of swelling

ceeded 100%. Squeezing the swollen specimens

(i.e., liquid could be squeezed out of the material)

forced out some of the liquid. Only nine of the

prior to the sheets separating. Eleven other chem-

thirty chemicals used in this study had little or no

icals (including the glacial acetic acid and the so-

effect on PVC. These chemicals were the neat

dium hydroxide solution) caused weight gains of

acid, the acid and hydroxide solutions, the two

1 to 10% (Table 5). None of these chemicals caused

alcohols, three hydrocarbons (gasoline, hexane,

any noticeable swelling or softening. Again, some

and kerosene) and carbon tetrachloride. In gen-

of the specimens showed frayed edges, although

eral, PVC is especially susceptible to degradation

this may have resulted from cutting or handling

by polar, non-hydrogen-bonded solvents.*

and not chemical exposure. As with FRE, the hy-

drochloric acid solution caused a slight loss in

weight (5%). FRP appeared to be unaffected by

hydrocarbons and the nonpolar chlorinated sol-

* Personal communication, Daniel C. Leggett, Research

Chemist, CRREL, 1994.

vents.

6

Previous Page

Previous Page