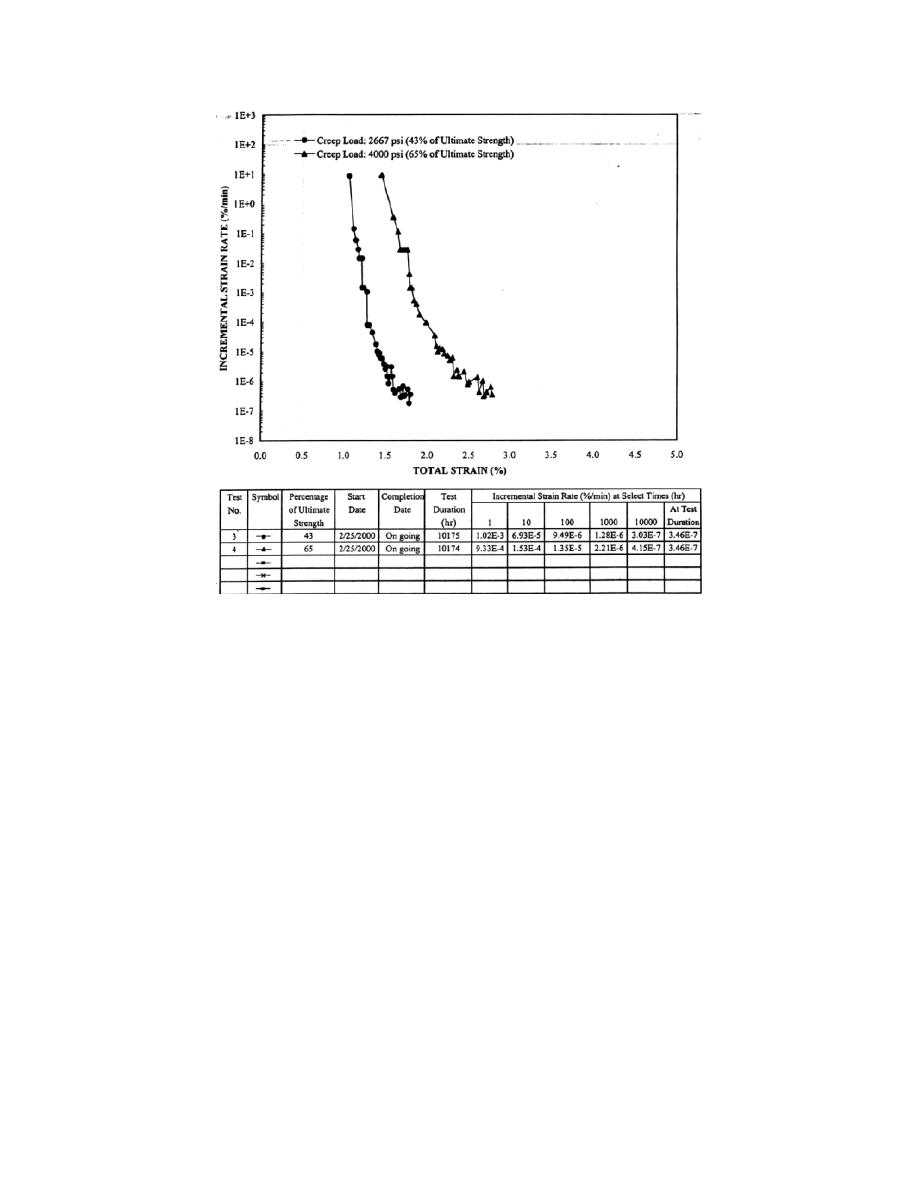

Figure 12. Creep rate decreases with time.

2.5% is predicted for creep limit of 4000 psi." The manufacturer suggests a design stress of only

3,200 psi, which is approximately 50% of the tensile strength (6,300 psi) of their material (Fig.

13).

Polymer Diagnostics Inc in their report "Model for the Prediction of Time and Temperature

Dependent Modulus of SU17A-1, 1998" to Crane Plastics Company, another manufacturer of

PVC sheet piles, predicts the shear stress relaxation modulus at various temperatures by a series

of curves as shown in Figure 14. This is another way of expressing the creep property of the PVC

as it varies with temperature. According to this manufacturer, the 30-year creep modulus for a

given PVC compound is roughly 45% of its initial modulus of elasticity. The creep modulus of

their standard sheet pile compound is 192,000 psi for 50 years and 211,000 psi for 30 years.

It is obvious that all three manufacturers recognize the creep problem in the vinyl, and they

recommend taking it up at the design stage by keeping the stress level below 4,000 psi and by

calculating deflection based on the 50-year creep modulus (211,000 psi).

Comparison of manufacturers' data

Manufacturers' data give crucial information about the performance of each of their sheet

piles. Their data were solicited by a questionnaire, a copy of which is given in Appendix A.

Appendices B1, B2, and B3 give responses received from three manufacturers. Gleanings from

these responses are presented in Table 2 for comparison.

15

Previous Page

Previous Page