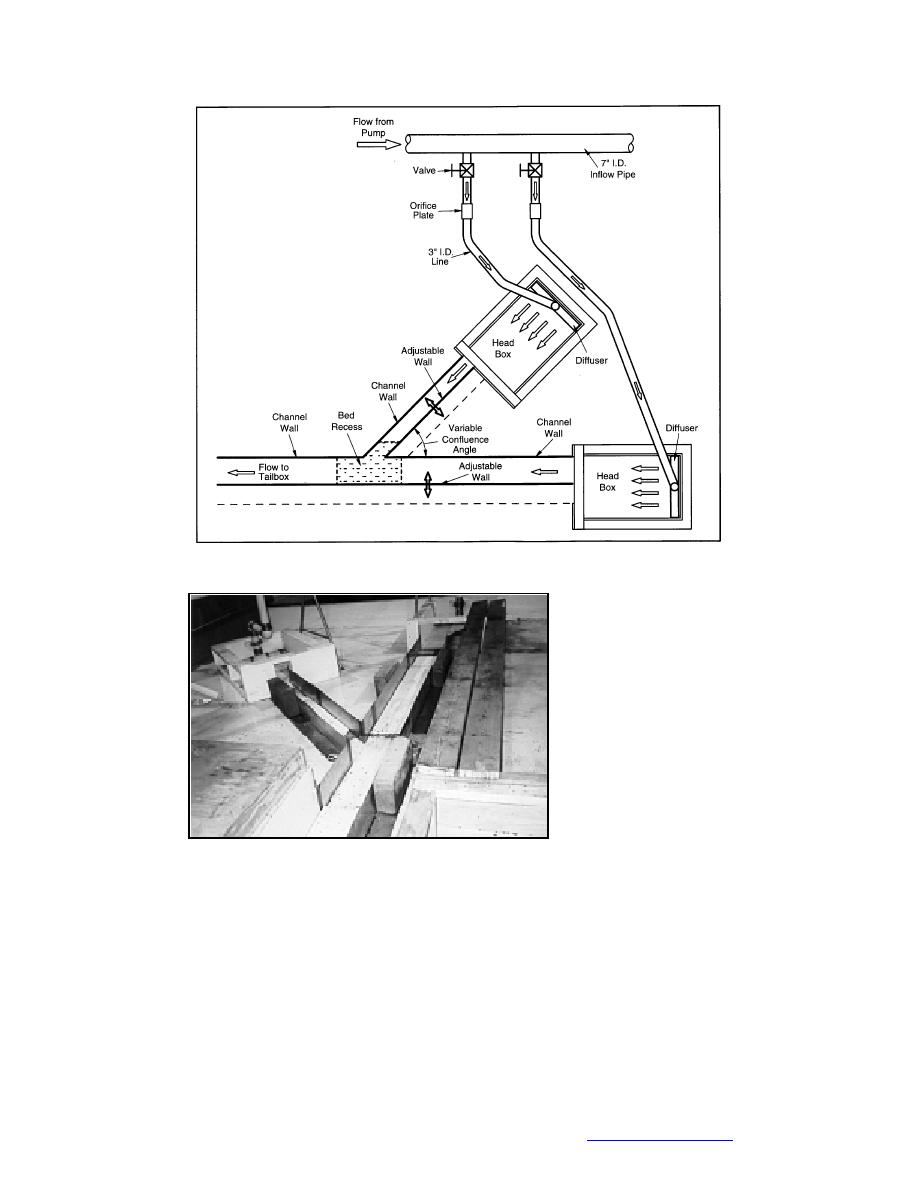

Figure 10. Layout of the jam process model.

channel downstream of

the confluence also was

sufficiently long that it

could re-establish uni-

form flow downstream

of the confluence. A tail-

gate positioned at the

model exit section con-

trolled the depth in the

channel.

The model channels

were constructed of sides

formed of folded sheet

Figure 11. View of the jam process model configured for a metal placed on a ply-

45 confluence.

wood channel bed or

base. The channel sides

were clipped together and anchored to the wood base by means of weights. This

construction technique provided a flexible design that facilitated easy and quick

re-arrangement of channel width and orientation. Most of the tests were conducted

with a flatbed confluence. For selected confluence cases, the tests were repeated

with simulated confluence bathymetry.

At the confluence, a piece of the wood bed was removable to create a recess in

which the bathymetric features of an alluvial confluence could be reproduced.

The features included those shown in Figures 10 and 11. Sand placed in the recess

was shaped to simulate the confluence bathymetry shown in Figure 4b. The sand

23

Back to contents page

Previous Page

Previous Page