occurred at the location the model predicted fail-

ure would occur. Failure was attributed to lower

snow strength near the surface and higher load-

ing conditions.

A final series of tests used a 1/10-scale model

of the tunnel. These tests, although limited in value

because of their proximity to the surface (0.6 m),

confirmed the data gathered in the previous, half-

scale tests. Catastrophic failure was initiated at twice

the anticipated loading of the full-scale tunnel.

THE SOUTH POLE TUNNELING SYSTEM

The CRREL South Pole Tunneling system

(SPoTs) is composed primarily of five major sub-

systems. These are the tunneler, the chip disposal

system, the surface drill rig, the generator set

(genset) module, and the workshop. The tunneler

and chip disposal subsystems were technically the

most challenging parts of the system and thus will

be discussed in greater detail. These subsystems,

as well as other components of SPoTs, are under

continuous development, as will be seen further

into this report. The descriptions below and fol-

lowing are thus a snapshot of the system at the

time of this report.

System overview

Before going into detail on the system compo-

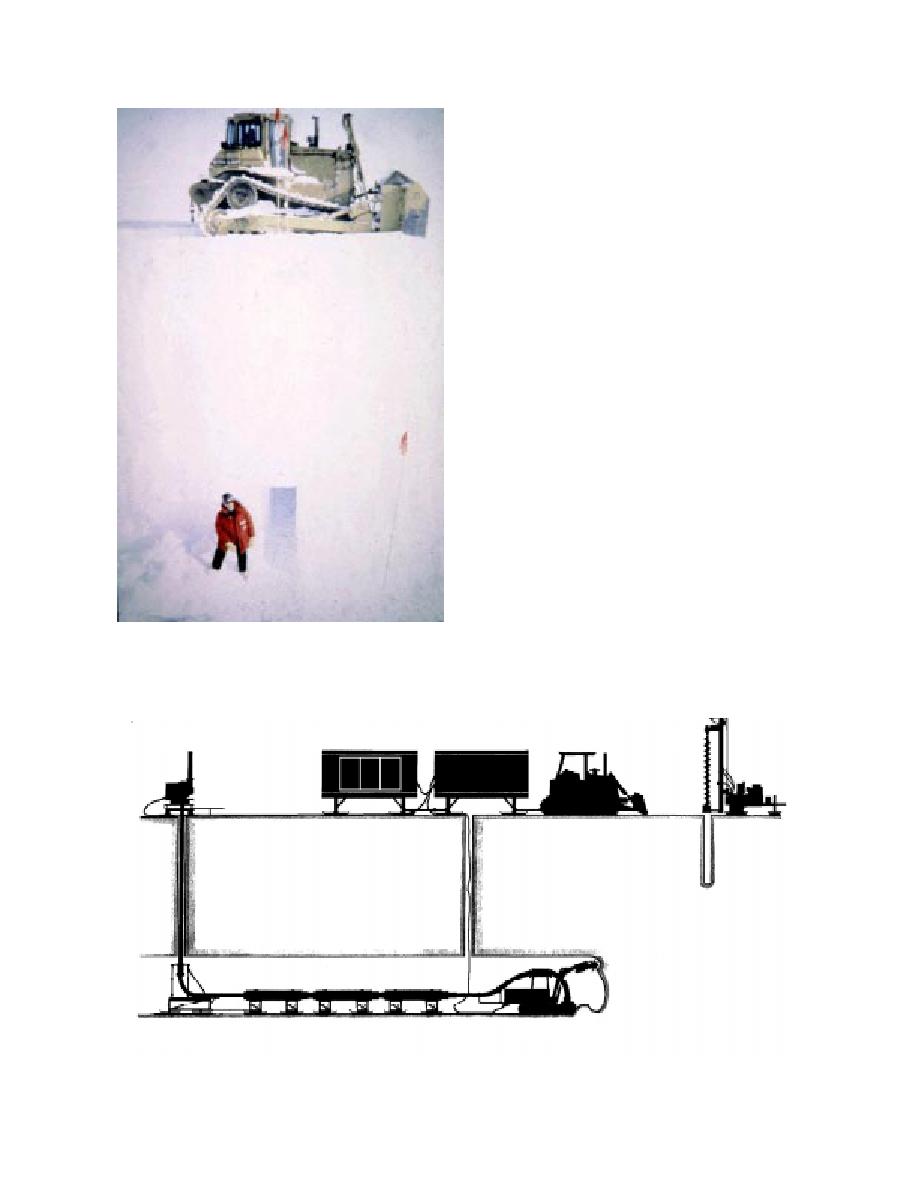

Figure 6. Scale model tunnel tests at South Pole.

nents, this report will present a brief system over-

view that will help orient the reader. Figure 7

shows how the system is integrated. As can be

Generator Module

Workshop Module

Blower

Drill Rig

Transition Sled

Tunneler

Telescoping Ducts

(conveyor collapsed)

Figure 7. The South Pole Tunneling System (SPoTs).

5

Previous Page

Previous Page