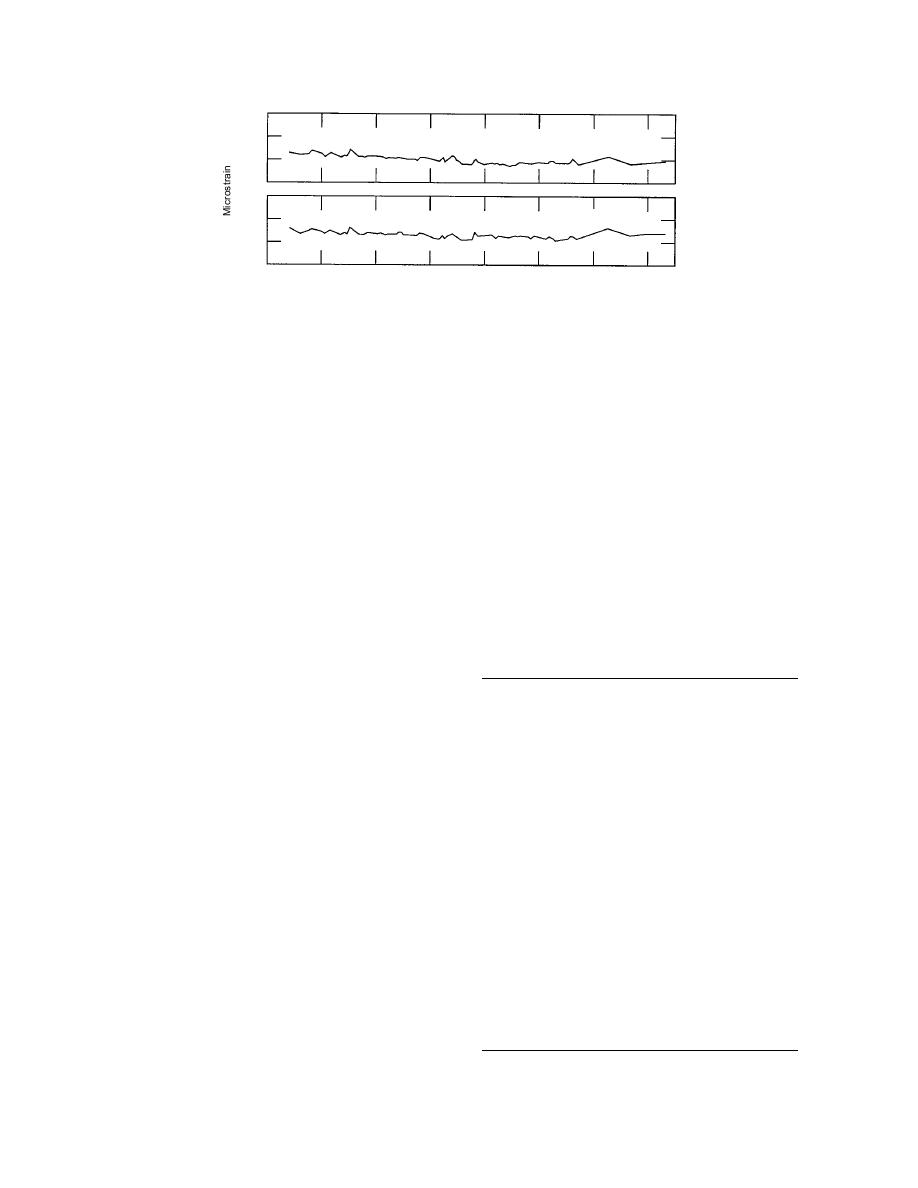

1250

1200

(a)

1150

1100

1350

1300

(b)

1250

1200

26 May

15 Jun

5 Jul

25 Jul

14 Aug

3 Sep

23 Sep

Period of Test

12.70-mm- (0.5-in.-) diam. rebar., and (b) 15.88-mm- (0.625-in.-) diam. rebar.

tively. If any creep occurred, the strain readings

a thermocouple sensor, and a third thermocouple

would continue to increase. However, the results

measured the air temperature of the chamber near

showed that over this period, the strain did not

the specimens. The specimens were again sub-

tend to increase. The temperature variation of the

jected to a long test period, from 25 April to 30

room in which the test fixture was placed caused

September, a total of 3,792 hours (158 days). The

the daily variation of the strain, as seen by the

strain readings taken approximately once a week

zigzag lines of the record, but the general trend

were remarkably steady over this period. The

did not reveal the development of any creep

numerical data recorded for this test are shown

under the test conditions.

in Table 16. Figure 63 gives the plotted data.

Since no creep could be detected at room tem-

perature, we expected no creep to occur at low

temperature (23C, 10F). However, creep might

have resulted if the low temperature induced any

Table 16. FRP rebar creep test data at 49C (120F).

microcracking or degradation of the interface bond

by the induced thermal stresses from the thermal

Chamber temp.

Microstrain*

Microstrain*

(F)

expansion coefficient mismatch between fibers

Date

in rebar no. 5

in rebar no. 6

and matrix. A relatively longer period of test was

04/25/94

120

1209

1281

necessary to develop these effects. Accordingly,

05/02/94

120

1209

1273

the deadweight test fixture was placed in a refrig-

05/09/94

119

1220

1279

erated coldroom, where the temperature was

05/16/94

119

1221

1274

constantly maintained at approximately 10C

05/23/94

120

1216

1273

06/01/94

120

1218

1276

(23F). This test was continued for 3,552 hours

06/07/94

120

1220

1270

(148 days). The strain records of the 12.70-mm (0.5-

06/15/94

119

1222

1276

in.) and 15.88-mm (0.625-in.) rebars are shown in

06/22/94

121

1211

1268

Figures 62a and b, respectively. Again, no discern-

07/01/94

119

1215

1269

07/05/94

121

1220

1272

ible trend of increasing strain was observed.

07/06/94

122

1220

1272

For the high-temperature (120F, 49C) creep

07/07/94

121

1215

1272

test, a special environment chamber of 1.22 1.22

07/15/94

121

1218

1275

2.44 m (4 4 8 ft) was built with a thermo-

07/21/94

118

1213

1273

statically controlled hot-air blowing system that

08/01/94

119

1217

1268

08/08/94

118

1216

1272

would control the temperature of the chamber to

08/15/94

121

1221

1276

between 50C (122F) and 47.2C (117F). At the

08/22/94

121

1223

1277

end of the coldroom test, the strain gages on the

09/01/94

122

1219

1276

15.88-mm (0.625-in.) rebars were damaged and

09/07/94

122

1221

1276

the bars themselves were unsuitable for further

09/15/94

120

1221

1271

09/20/94

121

1221

1271

testing. Accordingly only two 12.70-mm- (0.5-in.-)

09/30/94

118

1216

1262

diam. rebars were tested in the high-temperature

* Microstrain = strain 106

chamber. Each specimen was instrumented with

45

Previous Page

Previous Page