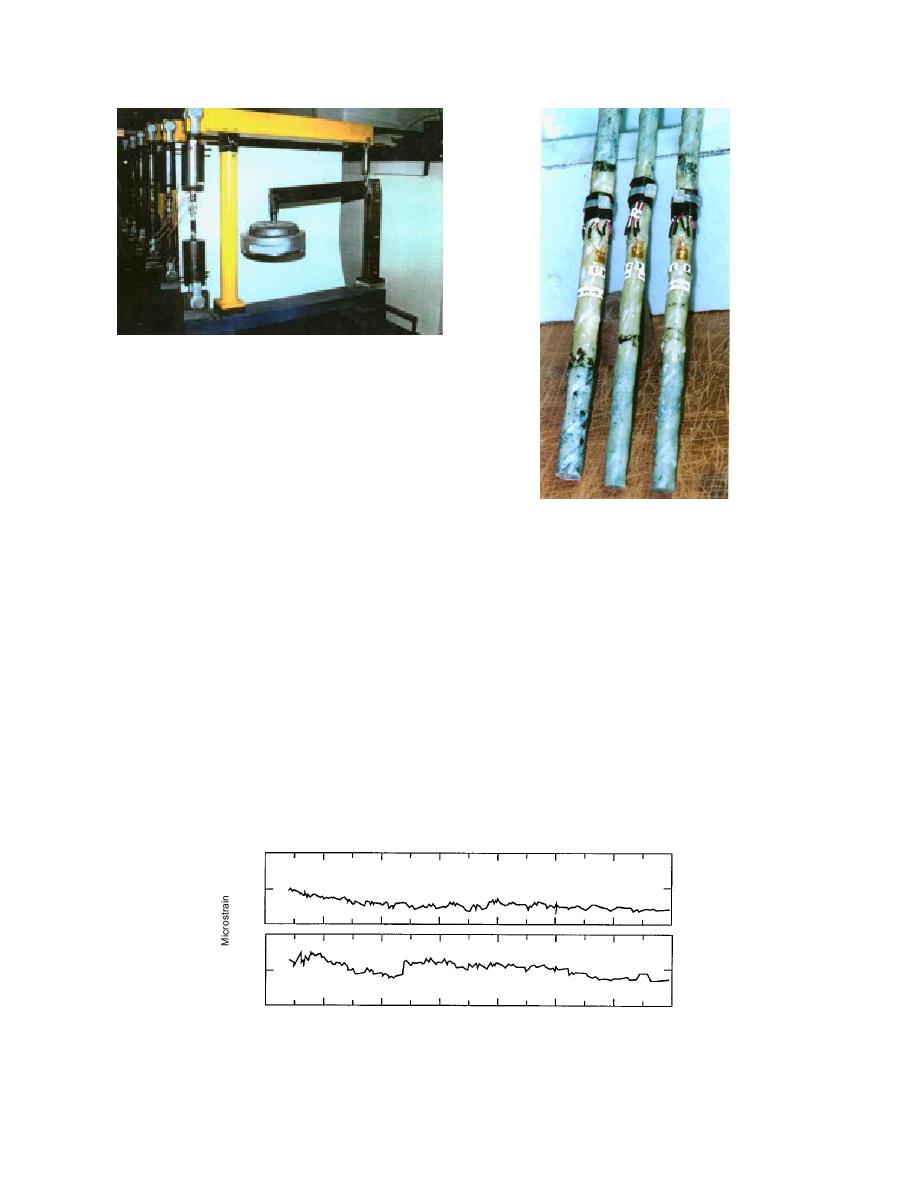

Figure 59. Creep test platform with six creep test

fixtures.

Each composite rebar was instrumented with

electrical foil strain gages to measure both the lon-

gitudinal and diametrical strains (Fig. 60). Even

though only longitudinal strains were of interest

in this creep study. The gages were centrally

located along the length of each specimen and dia-

Figure 60. Strain gage instru-

metrically opposite to each other. Each longitudi-

mentation on the test specimens.

nal gage was axially aligned with the fiber direc-

Test specimens shown removed

tion and positioned so as not to interfere with the

from the test fixture after the

spiral wrapping of the rebar. The gages had an

test was over.

effective length of 1.58 mm (0.062 in.), 350-ohm

resistance, and were temperature compensated for

The deadweights were adjusted to tension each

steel. The gages were bonded to the rebar surface

of these rebars to about 50% of its ultimate

according to the manufacturer's recommended

strength, as specified by the rebar manufacturer.

procedure. To avoid modifying the rebar speci-

In order to monitor temperatures, a thermo-

men resin, as per the gage manufacturer's instruc-

couple was attached to each rebar. Once the ten-

tions, the gages were cured overnight at room tem-

sion for the rebar was fixed, the apparatus was

perature. No elevated temperature curing was

not disturbed. For the room-temperature tests,

attempted. For measuring strain, each gage was

temperature and strain readings were taken once

put in a full-bridge configuration and initially bal-

a day for 1800 hours (75 days). The strain data

anced in a switching and balancing unit. All sub-

are shown in Figures 61a and b for the 12.70-mm

sequent readings were referenced to this initial

(0.5-in.) and 15.88-mm (0.625-in.) bars, respec

balance.

1.20 103

(a) 0.5 (a)rebar

in

1.15

1.10

1.30

(a) 0.625(in)rebar

b

1.25

1.20

31 Jul 91

20 Aug

9 Sep

29

19 Ot

8 Nov

28

18 Dec

Period of Test

Figure 61. Records of room-temperature creep strain for (a) 12.70-mm (0.5-in.)

diam. rebar, and (b) 15.88-mm (0.625-in.-) diam. rebar.

44

Previous Page

Previous Page