Table 15. Mechanical characteristics of composite rebars.

1.85 g/cm3 (0.067 lb/in.3)

Density

Ultimate tensile strength

117.9 MPa (17,098 psi)

54.206 GPa (7.86 106 psi)

Tensile modulus

9.9 10-6 mm/mm C (5.5 10-6 in./in. F)

Coef. of thermal expansion

Matrix

Derakane 411-45 polyester resin

Fiber

E-glass

Spiral fiber pitch

190.5 mm (0.75 in.)

4.2 in.

21 in.

Strain Gauge

1.5 in.

15 in.

Weight

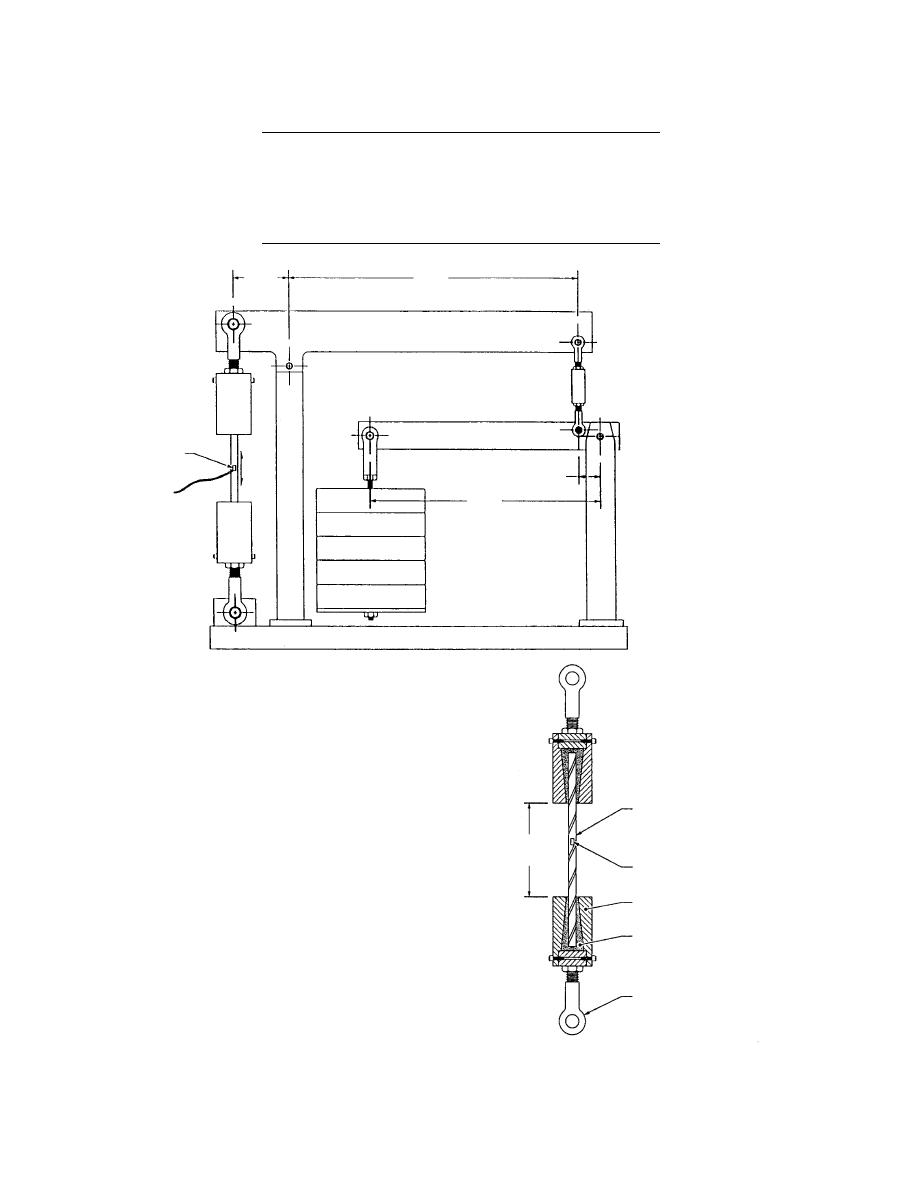

Figure 57. Deadweight

creep test fixture.

tics of these bars, as provided by the manufac-

turer, are given in Table 15.

To conduct the creep tests, the deadweight

creep test fixture shown in Figure 57 was designed

and fabricated. The gripping mechanism is shown

in Figure 58. The fixture provided a mechanical

advantage of approximately 50 to 1. Six of these

creep test fixtures were mounted on a common

Protruded Fiberglass Rebar

base frame (Fig. 59).

Initially, six fiberglass composite rebars made

6 in. Test

by a single vendor were selected for the tests. The

Length

Strain Gauge

rebars were obtained in 12.70, 15.88, and 19.05

mm (0.5, 0.625, and 0.75 in.) nominal diameters,

Gripper Housing

with a spirally wrapped glass fiber strand, wound

with an approximately 19.05 mm (0.75 in.) pitch.

Epoxy

The entire rod was redipped in resin and then

cured to obtain an irregular wavy but drip, sur-

face to promote adhesion to the concrete. For fix-

ing on the test jigs, the 19.05-mm- (0.75-in.-) diam.

Turnbuckle

rebar specimen proved to be the most difficult to

be gripped and was finally rejected from the test

batch. Only 12.70-mm- and 15.88-mm- (0.5-in.-

Figure 58. Details of the gripping mecha-

and 0.625-in.-) diam. bars were finally tested.

nism of the creep test fixture.

43

Previous Page

Previous Page