h2 30.4 2

same configuration as the original. This allows

=

110 35.6

much greater flexibility in operations due to the

greater available pressure range for dredging.

∴ h2 = 80.2 kPa @ 1280 rpm (11.6 psi).

The next factor to be examined is the power

requirement. For this, the classic fluid power

equation is used:

Adjusting for speed using the head/speed rela-

tionship,

P = (0.9751)pQ

(A10)

h2 n2

2

=

where P = required power (kW)

(A9)

h1 n1

p = system pressure (MPa)

Q = fluid flow rate (L/s).

where n1 is the original impeller rotational rate,

The impeller drive motor requires about 0.065

and n2 is the rate of interest,

liters per revolution. Table A1 illustrates the vari-

=

1800 2

h2

ous power requirements for different system con-

80.2 1280

figurations.

∴ h2 = 159 kPa (16.4-m head)

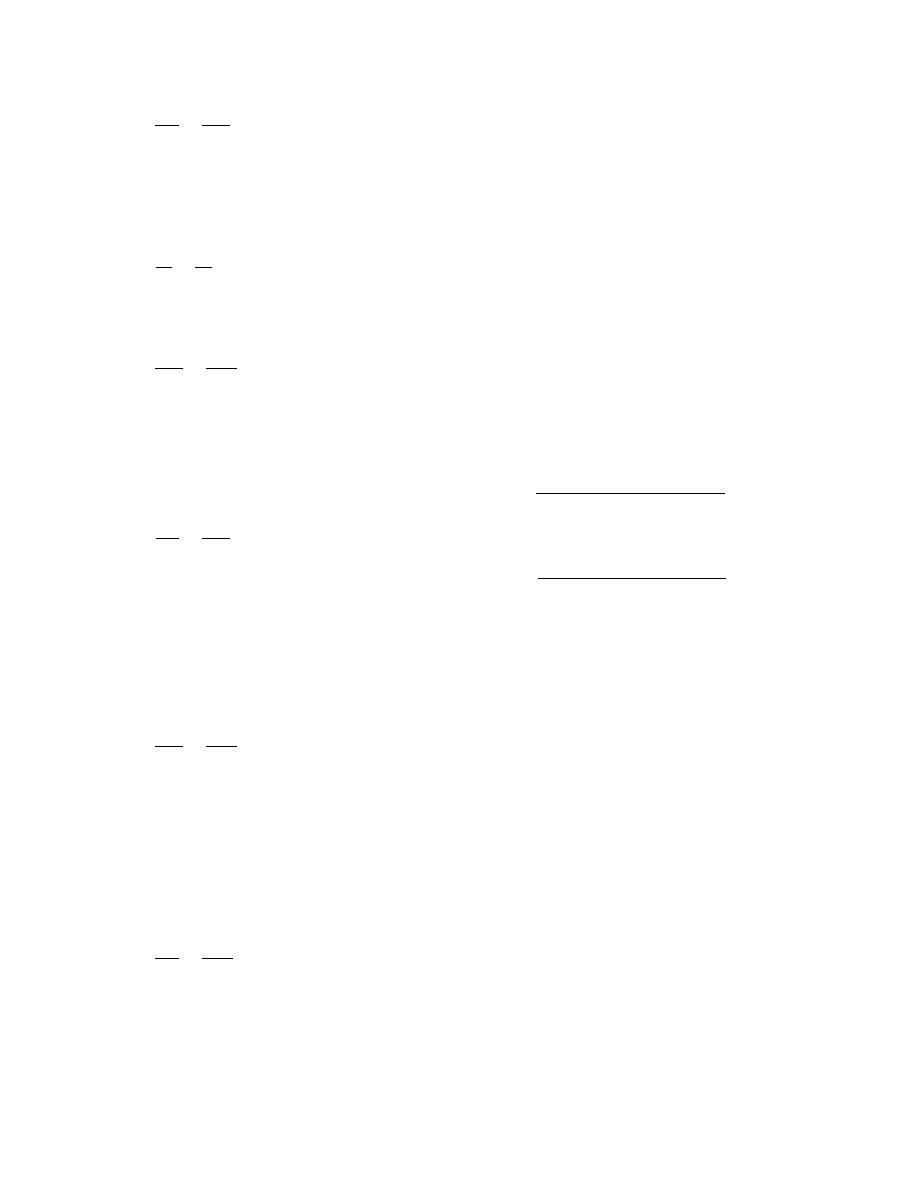

Table A1. Slurry pump power

@ 1800 rpm (23.3 psi @ 53.8 ft).

requirements.

Impeller

The next series of calculations are for a 330-

speed

Pressure

Flow

Power

mm (13-in.) trim. The equations used are the

(rmp)

(MPa)

(L/s)

(kW)

same, giving us

1280

24.1

1.4

32.9

h2 33.0 2

1280

31.0

1.4

42.3

=

(Ref. A8)

110 35.6

1500

24.1

1.6

38.6

1800

24.1

1.9

46.3

1800

31.0

1.9

59.5

h2 = 94.5 kPa @ 1280 rpm (13.8 psi)

(Ref. A9)

A total of 74.5 kW of power is available at the

∴ h2 = 187 kPa (19.2-m head)

electric motor driving the hydraulic pumps. Two

@ 1800 rpm (27.3 psi/62.9 ft).

other systems are driven off the auxiliary hydrau-

lic pump. The auger motor requires about 8.9 kW

Finally, for the 35.6-cm trim, we need adjust for

at full power, 80% efficiency, and the traverse

impeller speed only:

drive requires about 0.4 kW at the same condi-

tions. Using these numbers, a total of 65.2 kW is

=

1800 2

h2

available to drive the slurry pump. Using an effi-

(Ref. A9)

94.5 1280

ciency factor of around 80%, the greatest power

utilization comes at an impeller speed of just be-

h2 = 218 kPa (22.3-m head)

low 1500 rpm with line pressure at 31 MPa (4500

@ 1800 rpm (31.6 psi/73 ft).

psi). These are the conditions for which the 35.6-

cm impeller works best.

Referring to Figure A1, we should be capable of

Finally, the net positive suction head available

around 45 m (150 ft) of head. Lack of line resis-

(NPSHA) needs to be examined to ensure cavita-

tance is the probable cause of this differential. Re-

tion does not occur. The equation normally used

ferring back to Figure A2, the outlet head is calcu-

is

lated for an impeller speed of 1500 rpm:

NPSHA = ha + hs hfs hvp

(A11)

h2 1500 2

=

where ha = atmospheric head

(Ref. A9)

110 1280

hs = static suction head

h2 = 151 kPa (15.6-m head)

hvp = vapor pressure head.

@ 1500 rpm (22 psi /51 ft).

Atmospheric pressure is taken as 10.3 m. For stat-

ic suction head, the intake for the pump is 0.48 m

If the 35.6-cm impeller option is chosen, the outlet

below water level. Friction head loss is calculated

pressure should be about 151 kPa (22 psi) for the

23

Previous Page

Previous Page