Frost-Shielding Methodology and Demonstration for

Shallow Burial of Water and Sewer Utility Lines

BARRY A. COUTERMARSH AND DAVID L. CARBEE

INTRODUCTION

been needed is avoided, and time savings are asso-

In climates that experience freezing tempera-

ciated with excavating and backfilling a smaller

tures, water and sewer pipes are normally buried

trench. Reducing the burial depth to less than 1.52

below the depth of maximum frost penetration. In

m (5 ft) also eliminates the OSHA shoring require-

some areas of the country, this design depth can

ment, and can substantially decrease expense and

reach 2.5 m (8 ft) (Nayyar 1992). A shallower

increase productivity.

trench is desirable in many situations. If ledge is

One of the major impediments to insulating pipe-

present, the cost of blasting and removing it can

lines routinely is the lack of design guidance for the

make the excavation quite expensive. Further-

insulation configuration and thickness. The design

more, frost penetration

of the shield is affected

is normally deeper in

by the variables of cli-

ledge than in other

mate, burial configura-

soils, thus exacerbating

tion, soil characteristics,

the situation. If the in-

and pipe temperature.

situ material is envi-

The designer must also

ronmentally sensitive

choose an acceptable

or otherwise difficult or

"freeze time," i.e., an

expensive to excavate, a

amount of time before

shallower trench could

the pipe freezes if there

save both time and

is no flow (and thus no

money. If isolated ob-

heat) within it. CRREL

structions or other util-

has developed a finite

ities are encountered

element (FE) program

during the pipe instal-

that allows the designer

lation, an elevation

to assess the impact of

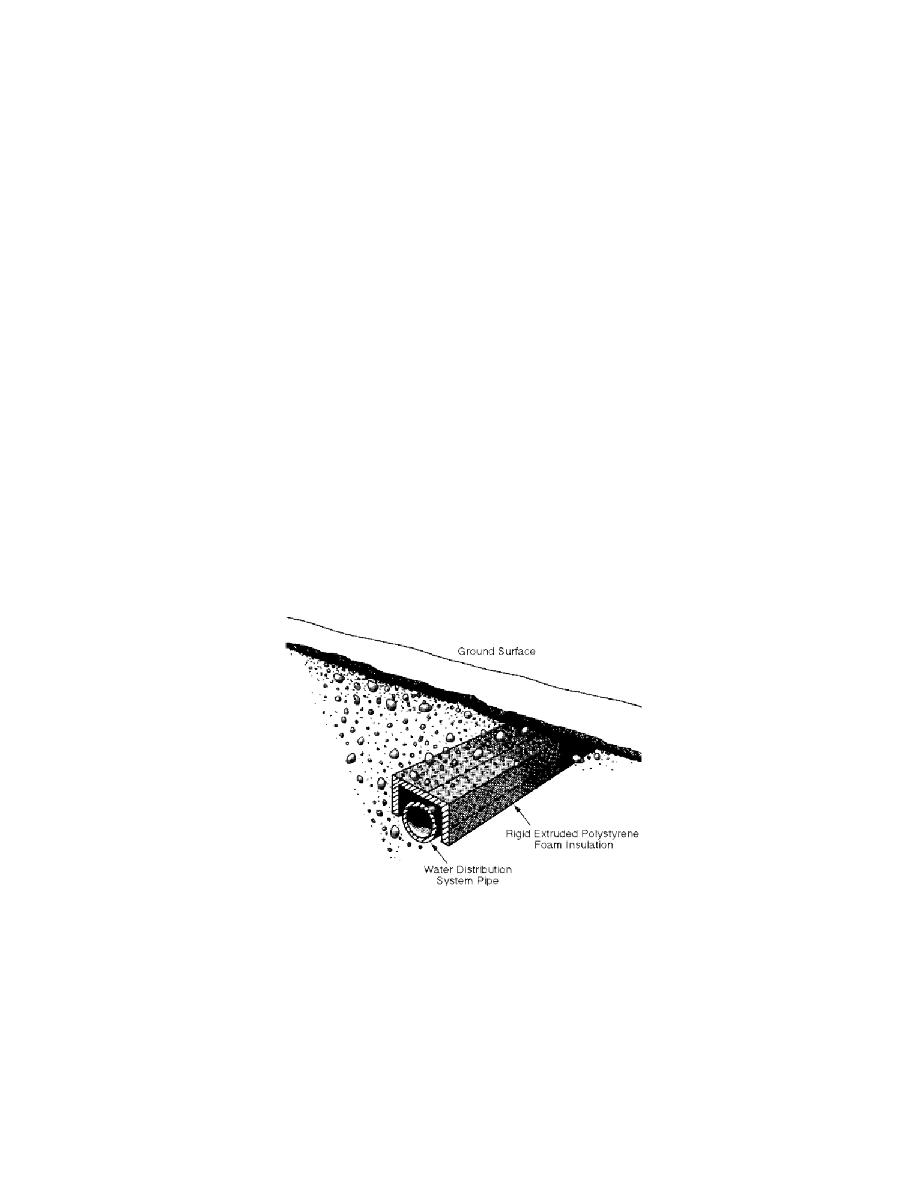

change over the ob- Figure 1. Example of inverted-U frost shield around pipe- each of the variables and

struction might be de- line.

see how the changes

sirable.

affect the freeze time.

Frost shielding is the technique of placing

The program models two-dimensional subterra-

insulation in some configuration around a pipe to

nean heat flow, with phase change, and describes

protect the pipe from freezing, as shown in Figure

the results both numerically and visually using

1. The increased cost of the insulation and the time

graphs and contour plots. This program allows the

to install it are balanced by savings in time and

designer to create several different shield configu-

money afforded by decreased burial depth: a

rations and assess the thermal performance of

smaller amount of material needs to be removed

each. A cost analysis can then be performed to

and discarded, the extra backfill that would have

determine the most efficient shield design to use.

Previous Page

Previous Page