channels) and the whole cycle would start over

could likely wait until after the entire event has

again.

been recorded. For random or regular querying

Signal processing requires a fairly robust sys-

of stage, however, some modifications would be

tem to process and continuously update values,

required. An instantaneous value of stage could

and a fairly decent signal-processing algorithm

be substantially in error if waves, ice, or debris

needs to be developed to account for false values

happen to be passing through the radar scan at

(e.g. if a bird or large debris passed through the

that particular moment. Assuming the device is

radar beam). The unit used by Yankielun and

connected to a DCP, a stage value will be queried

Ferrick was composed of individual components,

at the given time interval for the gage (generally

which is adequate for research instruments, but a

every 15 minutes to four hours). A typical proce-

field unit would need to be more compact and self-

dure would be to sample stage for the period of

contained. The unit would need careful siting to

time necessary for adequate accuracy, processing

operate within its operating parameters.

the data, time-averaging the stage values, and

There are occasions when only the peak stage

transmitting the computed value. This would re-

associated with an ice jam event is desired at a

quire the radar to be "told" ahead of time when to

remote location. The USGS frequently uses crest-

sample, which may be difficult if the DCP is in a

random report mode. Another option would be

stage gages (Rantz et al. 1982a) in flood flow fre-

quency studies to record maximum peak stages

to sample stage continuously between DCP que-

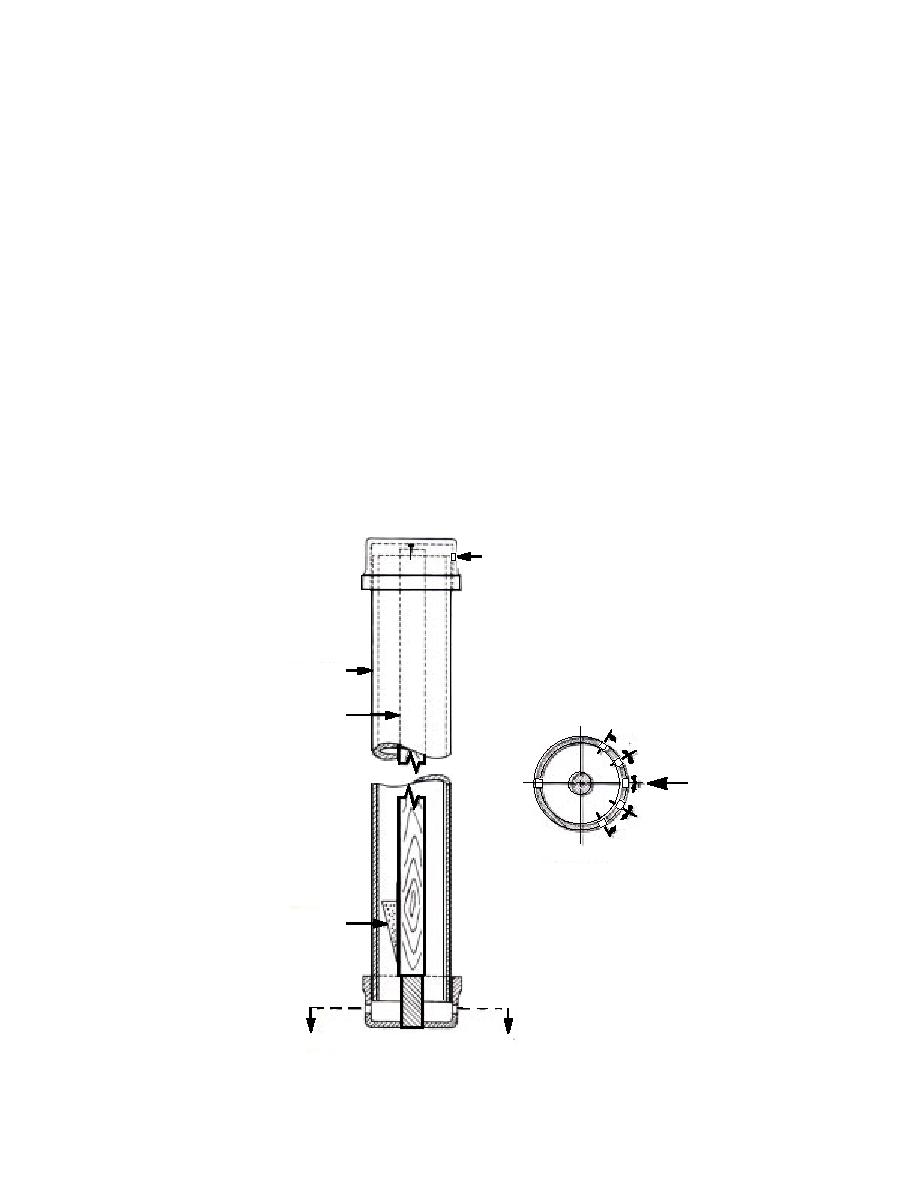

in known jam locations. These gages (Fig. 12) con-

ries, processing stage data and continuously up-

sist of a galvanized pipe with holes drilled near

dating the time-averaged stage. The average stage

the bottom that is installed in the streambed. A

and maximum and minimum stage could then be

transmitted (provided the DCP has enough free

graduated rod or staff is placed within the pipe at

3/16-in. Vent Hole

2-in. Pipe

1/4-in. Intake

3/4-in. by 1/2-in.

Holes

Measuring Stick

30

Flow

30

30

30

Section A - A

Perforated Tin Cup

For Regranulated

Cork

A

A

Figure 12. USGS crest stage used to measure peak stage (after Rantz et al. 1982).

20

Previous Page

Previous Page