Technical assumptions

The major technical assumptions that we make are related to the heat load

characteristics and the method by which the heat load is met. In district heating

systems, the amount of heat supplied can be varied to accommodate varying

demand by adjusting either the supply temperature or flow rate. However, certain

constraints imposed by consumer equipment and minimum temperature re-

quirements must be observed. In larger systems, both the supply temperature and

flow rate are varied over the course of the year. In small systems, which must adopt

simpler control strategies, often only the flow rate is varied. For the sake of

simplicity, we assume the latter here and assume that the supply and return

temperatures remain fixed over the yearly cycle. This is never actually the case, but

for system design, it is felt that this is an appropriate simplifying assumption for a

first analysis. Ideally, for example, the supply temperature, return temperature and

flow rate at the consumer would be determined by the heat transfer characteristics

of his heat exchanger under the prevailing load. A model that simulates the

consumer's heat exchanger is developed in Chapter 3, but here it is not considered.

The actual heat load in district heating systems has several major components. A

detailed treatment of the heat load would be difficult and is not warranted for design

purposes. For an excellent treatment of the actual heat loads in operating district

heating systems, see Werner (1984). The assumption we make here for design

purposes, that the heat load can be approximated as sinusoidal, is supported by the

data presented by Werner (1984) as well as by the data of Phetteplace et al. (1981).

We assume here that the heat load varies sinusoidally from a minimum of 15% of its

maximum value to its maximum value. The assumed minimum load of 15% would

result primarily from hot tap water use and heat losses from the pipelines. Thus,

with our assumption of constant supply and return temperatures, the mass flow rate

as a function of time is

m / md = 0.575 + [0.425 cos(2πt/8760)].

˙ ˙

(2-28)

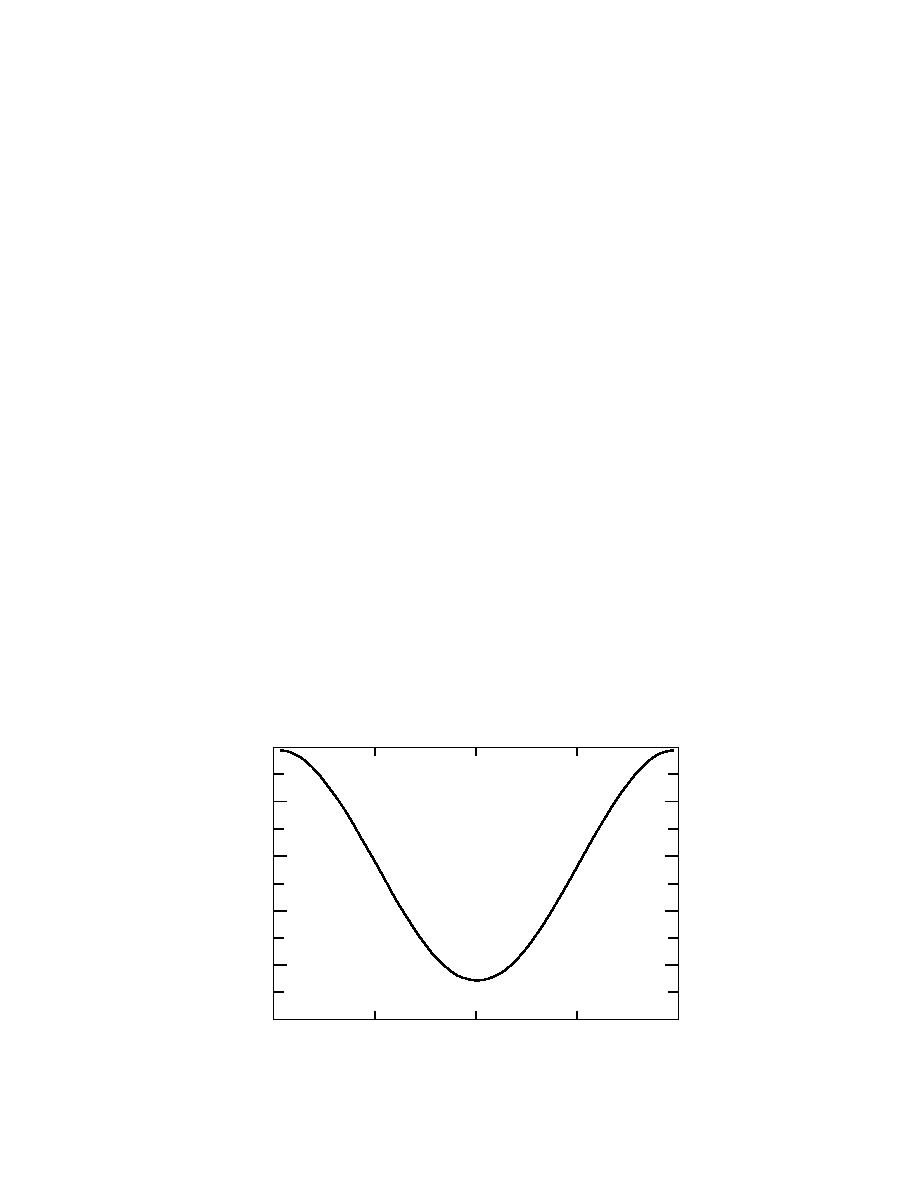

The ratio of the mass flow rate to its maximum value as determined by eq 2-28 is

shown in Figure 1. With this simple function for the load curve, it is easy to determine

the shape of what is normally referred to as the "load duration curve." Since eq 2-

1.0

0.8

0.6

m/md

0.4

0.2

0

2190

4380

6570

8760

t (hr)

Figure 1. Assumed annual load curve.

13

Previous Page

Previous Page