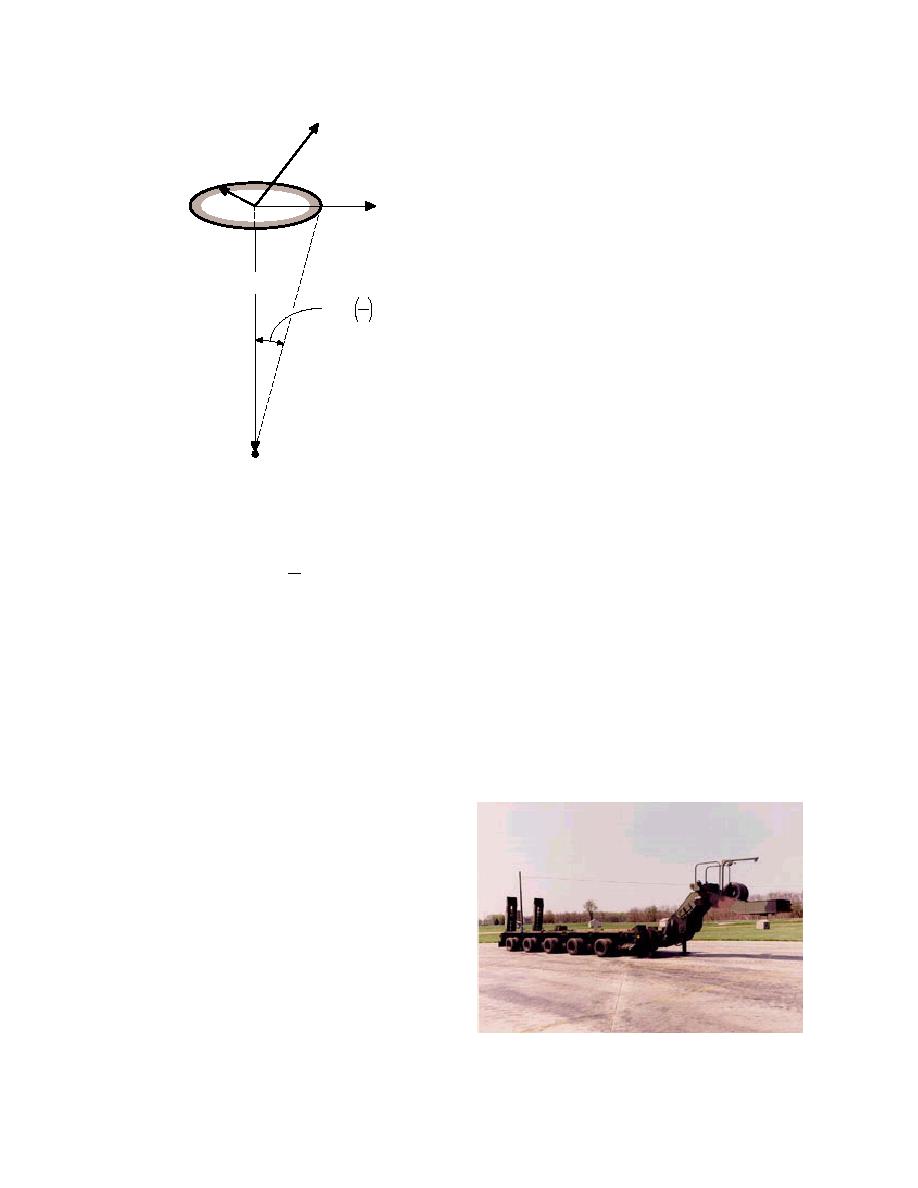

uted over a rectangle (Fig. 4). Based on the informa-

y

tion given in Figure 4, the L:B ratio of the uniformly

loaded rectangle is approximately 3.9. Note that for a

1-m depth of aggregate, V is equal to 1.16 for this ve-

hicle.

r

x

ANALYTICAL STUDY AND RESULTS

I programmed eq 2 and 3 into a Mathcad 8 pro-

z

grammable worksheet (Mathsoft 1998) and set the area

r

tan1 z

of pressure application equal to one. The results gen-

erated include the fraction of the applied vertical stress

below the rectangle and the circle, Irect and Icirc, respec-

tively, and the ratio Irect/Icirc. A factor F represents the

L:B ratio that was easily changed to examine its influ-

ence on results. Appendix A contains a hard copy of

the Mathcad worksheet used, tabulated results, and a

copy of the Mathcad worksheet for the reader's use.

The ratios of the stress reduction beneath the center

Figure 2. Uniformly loaded circle,

of the rectangles to the stress reduction beneath the

showing notation used in the esti-

center of a circle are shown in Figure 5. The maxi-

mation of vertical stress at depth

mum vertical stress beneath the circle is always greater

below the center of the circle.

than that beneath the rectangles, including the special

case of a square. A circle minimizes the ratio of perim-

3

r

eter to area; thus, the circle maximizes the influence

Ic = 1 - costan -1

Z

.

(3)

of surface pressure at depths below the center. There-

fore, applying the assumption that the surface load is

I used eq 2 and 3 for a unit uniform load and a unit

circular is conservative compared to assuming other

area to compare the stress reduction at various nor-

shapes. Furthermore, for length/width ratios of 3 or

malized depths estimated by each equation. I varied

less, the maximum vertical stress applied by a rect-

the length/width ratio of the rectangles from L = B to L

angle is at least 85% of that applied by a circle. The

= 6B and the normalized depth Z from 0.05 to 2.0. The

minimum ratio of the stress beneath a rectangle to a

range in these parameters reasonably represents the

circle for the conditions analyzed occurs at a normal-

geometry of loads applied by heavy military vehicles.

ized depth of about 0.6, and is about 0.65 for a length/

An example of estimating the length-to-width ratio of

width ratio of 6. As mentioned earlier, the length/width

a wheel load and the values of V and r for a military

ratio of 6 is outside the range of load shapes for wheeled

vehicle follows.

U.S. military vehicles.

WHEEL LOAD GEOMETRY

OF THE M1000 TRAILER

On-highway trucks typically have L:B ratios of 1.4

and off-highway trucks have L:B ratios of 2.0 (Giroud

and Noiray 1981). The M1000 trailer of the Heavy

Equipment Transporter System (HETS) (Fig. 3) likely

has the highest length/width ratio of a wheel load ap-

plied by a U.S. military vehicle. Each axle line of this

trailer has eight wheels (two sets of dual wheels on

each end) (Fig. 4). If we assume that the soil between

the tires aligned on one side of the axle will not fail

(e.g., Giroud and Noiray 1981), then the load carried

Figure 3. M1000 semi-trailer, downloaded from

on that side of the axle can be assumed to be distrib-

USA TACOM (1999).

3

Previous Page

Previous Page