Stage 1

Stage 2

Stage 3

Chemical

Gravity

Shear and Compression

Conditioning

Dewatering

Conditioned

Sludge

Sludge

Wash Spray

Sludge

Polymer

Mixer

Polymer

Solution

Dewatered

Wash Spray

Filtrate

Sludge

Cake

Wash Water

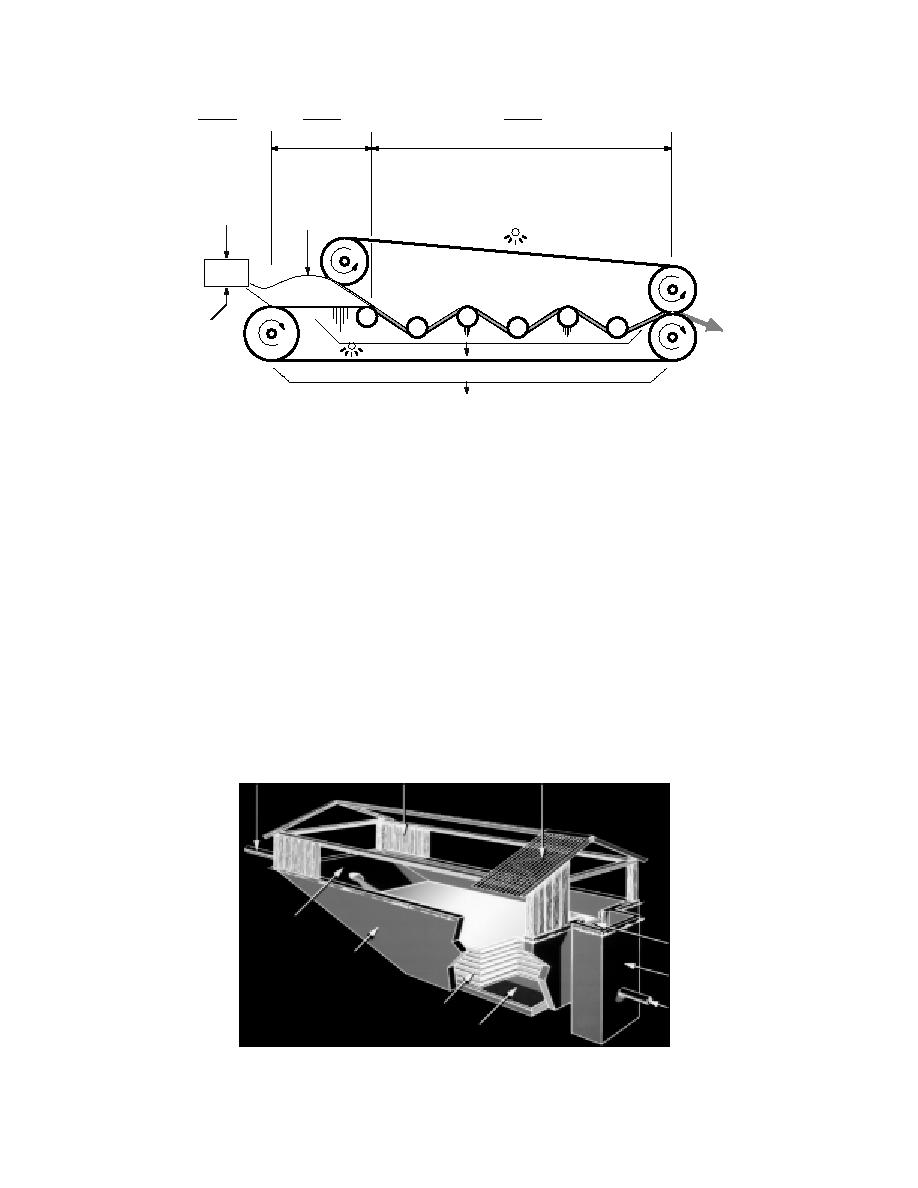

Figure 1. Schematic of belt filter press.

tion. Aerobic digestion is proposed for sludge stabili-

plant. A preliminary design is developed here that is

zation followed by a belt filter press for dewatering. In

based on average climatic data at McMurdo and the

this analysis, I assumed that all components of a treat-

sludge quantities reported by CTE (1999).

ment system would be the same except that a freezing

bed would used instead of a belt filter press. The vol-

DESIGN CRITERIA

ume of sludge that needs dewatering is projected to be

178 m3 (47,000 gal.) annually.

Currently, wastewater generated at McMurdo only

receives maceration (grinding) prior to being dis-

The horizontal dimensions of a freezing bed depend

charged into McMurdo Sound. Although it is not re-

on the depth of sludge that can be frozen and thawed

quired by treaty, the goal of NSF is to provide a level

at the proposed site and the volume of sludge to be

of wastewater treatment consistent with the 1972 Clean

processed. The depth of sludge that can be frozen and

Water Act. To achieve this goal, a secondary treatment

thawed depends on the climatic conditions at the site.

plant will be required.

The monthly average air temperatures and insolation

CTE Engineers evaluated several secondary treat-

at McMurdo Station can be found in Table 1. These

ment alternatives and recommended extended aeration

data show that the average temperature is below freez-

followed by low pressure ultraviolet (UV) disinfec-

ing during each month. Consequently, freezing sludge

Incoming Sludge Pipe

Louvered Sides

Transparent Roof

Vehicle Access Ramp

Overflow

Weir

In-Ground Concrete Tank

Sump

Overflow

and Filtrate

Frozen Sludge Layers

Return Pipe

Sand Bottom

Figure 2. Conceptual drawing of freezing bed.

2

Previous Page

Previous Page