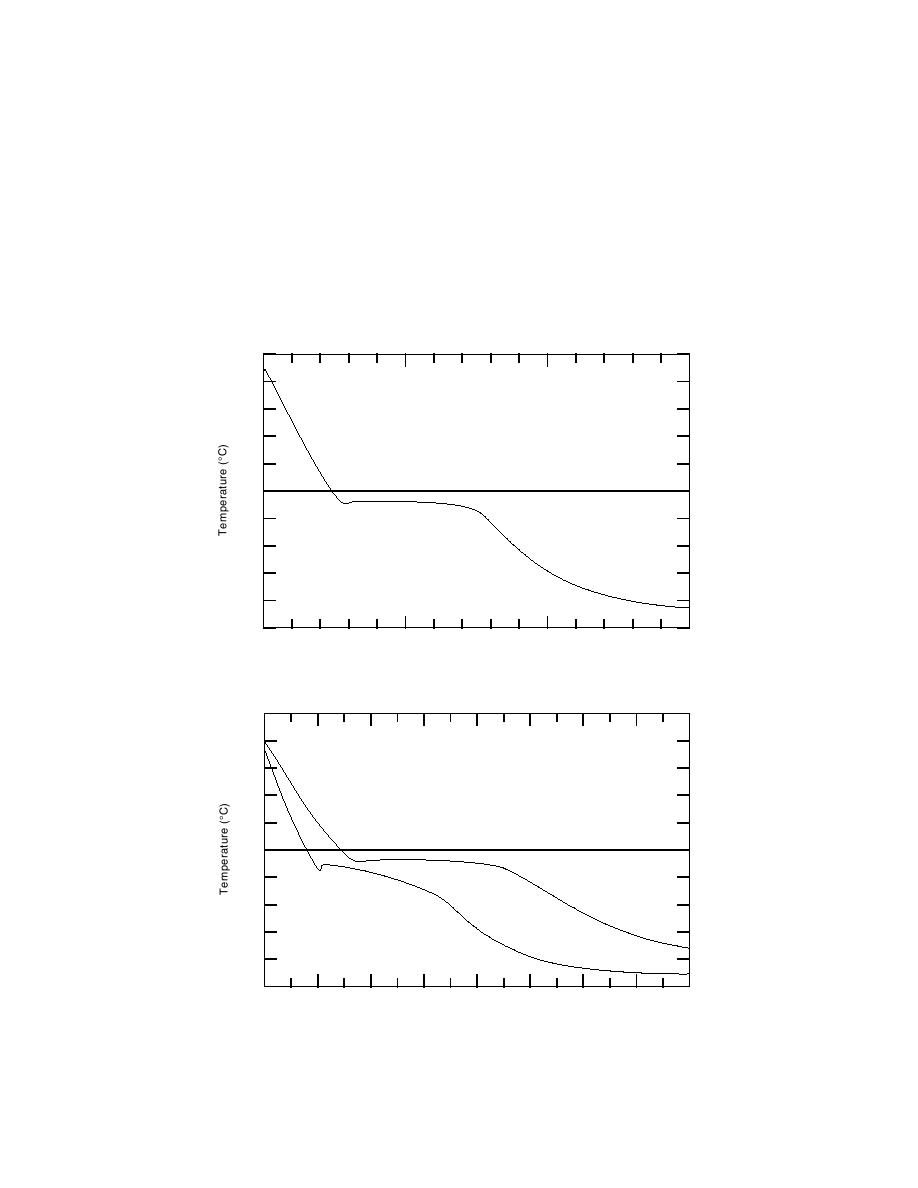

an hour compared to control. Better temperature con-

taining two doses of accelerating admixture on the other.

trol should produce results that are more consistent.

In general, the three curves show that mortar steadily

Despite the apparent problems with the temperature

cools from room temperature to the point where ice

of the room, the useful conclusion from these tests was

suddenly appears. This event is easily identified on all

that the accelerator doses could be much higher than

three curves as the location where the initial slope

those recommended by the manufacturer, especially in

changes. However, a close inspection of each curve

cold weather.

reveals that there are two temperatures to choose from

The freezing points were determined by embedding

at this juncture. For example, the control mortar gradu-

ally cooled from 22C (71.6F) to 2.3C (27.9F)

thermocouples into cylinders of fresh mortar placed into

a 20C (2F) room. Figure 1 shows how the tem-

before suddenly rising to 1.9C (28.6F) and holding

perature changes as thermal energy is extracted from

there for many hours. The lower of the two tempera-

tures represents the instant at which ice spontaneously

control mortar on the one hand, and from mortars con-

25

20

15

10

5

0

5

10

15

20

25

0

150

50

100

Time (min.)

a. Control mortar.

25

20

15

10

5

0

5

Low

10

15

High

20

25

20

40

60

80

100

120

140

0

160

Time (min.)

b. Two mortars made with a low and high dose of ASTM Type C accelerator.

Figure 1. Cooling curves.

4

Previous Page

Previous Page