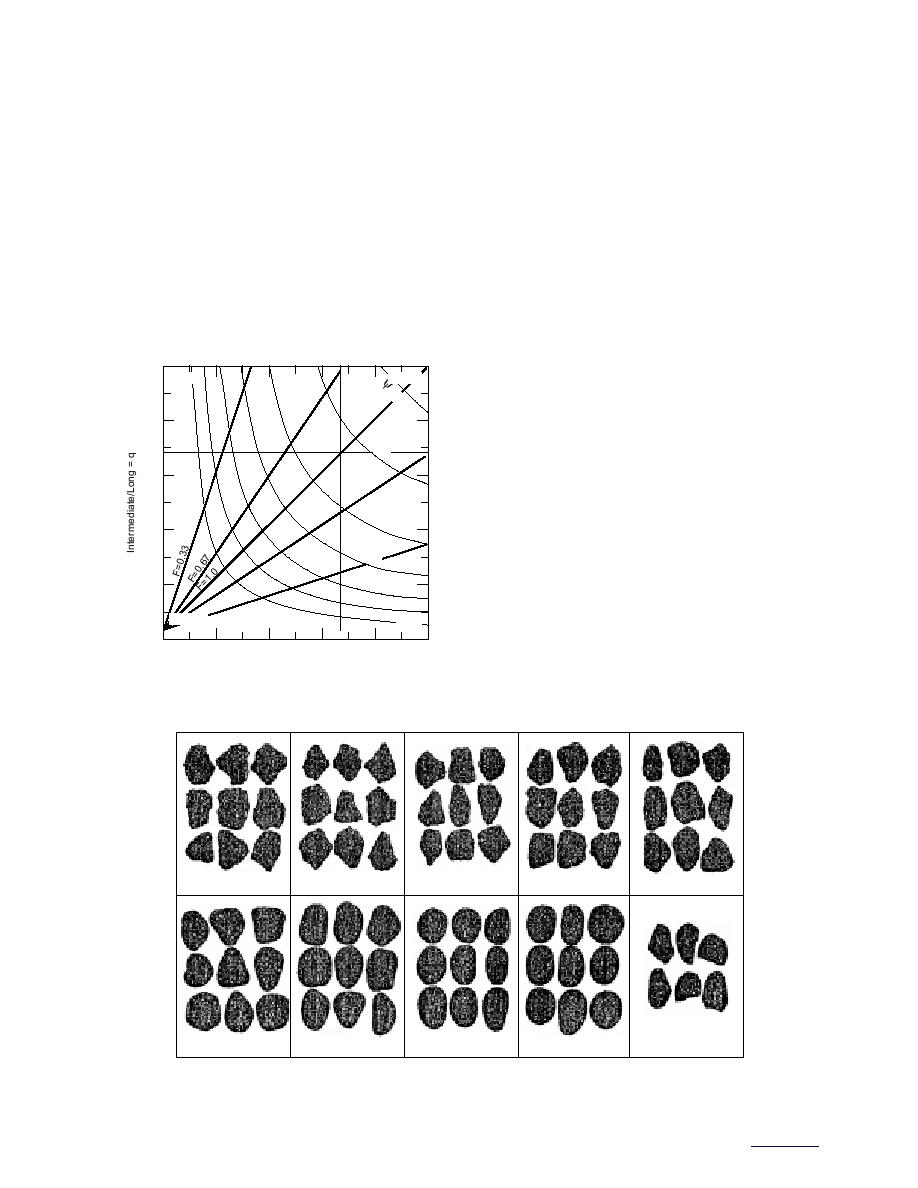

petrologists, the shape of a coarse aggregate can

based image analysis has been developed for anal-

be described by its length, width, thickness, sphe-

yzing aggregate shape, angularity, and rough-

ricity, roundness, and angularity. Aggregate clas-

ness. A feasibility study conducted for the Federal

sification charts to evaluate shape, roundness,

Highway Administration (FHWA) on this tech-

and angularity of aggregates are shown in Figures

nology (Wilson et al. 1995) showed that image

2, 3, and 4. Surface texture is more difficult to deter-

analysis is a viable tool for distinguishing the

mine. Traces of magnified surfaces have been

shape and angularity of fine sands (manufac-

used to describe surface texture (Wright 1955).

tured vs. natural). The method involves first cap-

Others, such as Barksdale and Itani (1994), devel-

turing magnified images of the aggregates using

oped roughness scales to describe the texture of

a high-resolution video camera, and then using

an image analysis program to identify and separate

aggregates.

the objects and trace the edges of the aggregates.

For fine aggregates, shape and angularity can

Based on the traces, algorithms in the programs

be described with image analysis. Computer-

are used to determine the different characteristics

of the aggregates. The Quebec Ministry of Trans-

1.0

DISC

CUBIC

portation (QMOT) routinely uses image analysis

=

0.

95

of the HMA fine aggregates to distinguish round-

ness and angularity of the fine aggregates. Addi-

0.8

ψ

tional descriptions of this method can be found in

=

0.

Janoo (1998).

9

An alternate approach taken by engineers is to

0.6

infer these characteristics from the mass properties

of the aggregates. Several indices such as angu-

ψ=

0.8

larity number, time index, particle index, and

0.4

ψ=

rugosity have been identified in the literature.

0.7

For coarse aggregates, the angularity number

ψ= 0

(AN) developed by Shergold (1953) is recom-

5

0.2

.6

1.

ψ = 0.5

F=

mended by the British Standards Institution

.0

ψ = 0.4

F=3

(1989) for indexing the angularity of natural and

BLADE

ROD

crushed aggregates used in concrete. This tech-

0.0

0.0

0.2

0.4

0.6

0.8

1.0

nology can be easily transferred to HMA. Sher-

Short/Intermediate = p

gold found that when the aggregates were com-

pacted in a prescribed fashion, the percentage of

Figure 2. Aggregate classification chart.

Roundness = 0.4

Roundness = 0.5

Roundness = 0.1

Roundness = 0.2

Roundness = 0.3

0.3 0.4

0.4

0.5

0.5

0.4

Roundness = 0.9

Broken Pebbles

Roundness = 0.6

Roundness = 0.7

Roundness = 0.8

Figure 3. Roundness chart for 16- to 32-mm aggregates.

3

to contents

Previous Page

Previous Page