duction of stone matrix asphalt (SMA) mixtures

ing aggregate tests and asphalt concrete perfor-

in the USA.

mance (Kandhal and Parker 1998). The study,

To minimize rutting, aggregate interlock is

based only on laboratory evaluation, recom-

crucial. The shape, angularity, and surface texture

mended a set of aggregate tests that relate to rut-

of the aggregate affect the interlock. However, this

ting, fatigue cracking, raveling, and stripping

interlock appears to be critical for the fine aggre-

performance of HMA pavements (Table 1).

gates, as noted by Uge and Van de Loo (1974),

This report discusses test methods proposed by

who reported that use of rounded coarse aggre-

NCHRP for rutting susceptibility and focuses on

gate with crushed fine aggregate also produced

the two areas not covered by the NCHRP report:

rut-resistant HMA mixtures (Fig. 1). A discussion

skid resistance and freezethaw durability charac-

terization. The report also focuses on aggregate

of the various factors that affect pavement rutting

characterization and not on test methods that

can be found in Janoo (1990).

involve mixture testing.

The quantification of the shape, angularity,

and surface texture of an aggregate is difficult but

not impossible. Several methods involve either

PARAMETERS AND TESTS INDICATIVE

direct measurements of aggregate or indirect

OF RUTTING PERFORMANCE

inference from aggregate properties or from mix-

Particle shape, surface texture, particle size,

ture testing. For example, for coarse aggregates,

pore structure, and particle strength appear to be

engineers have developed visual classification

the most common characteristics cited for con-

methods to characterize shape and angularity or

trolling rutting.

index tests that use engineering properties such

Permanent flow or rutting from traffic loading

as porosity to speculate on the shape, angularity,

is due to densification and plastic flow of the

and surface texture of aggregates. In the index

HMA mixture at high temperatures. Factors such

test developed by engineers, however, it is not

as asphalt content, asphalt grade, air voids and

possible to quantify separately the shape, the

aggregate characteristics, construction practices,

angularity, or the surface texture. Usually they

temperature, and increase in traffic load/repeti-

are lumped together as geometric irregularities.

tions all have an influence on the rutting potential

Details on quantification of the shape, angularity,

of a mixture. Although all these factors are impor-

and surface texture of aggregates can be found in

tant, the effect of aggregates, which comprise up

Janoo (1998). For coarse aggregates, geologists

have a sophisticated system that involves physi-

to 90% of the mixture, plays a significant role in

cal measurement of the aggregates. As used by

controlling rutting, as seen by the recent intro-

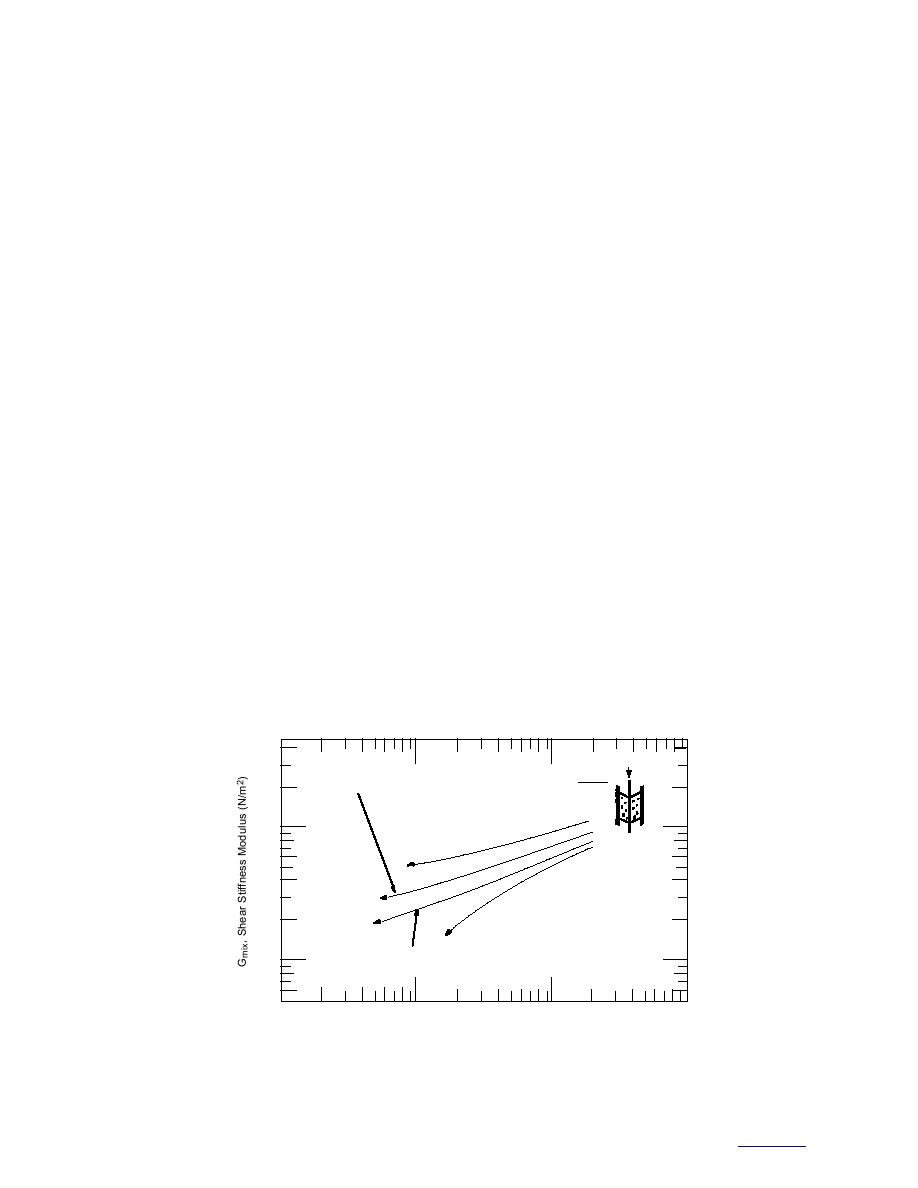

4x108

τ mix

30% Crushed Materials (0/2 mm)

Gmix =

70% Rounded Materials (2/12 mm)

γ mix

107

100% Crushed Aggregates

100% Rounded Aggregates

25% Rounded Materials, 75% Crushed Materials

106

(2/12 mm)

(0.08/2 mm)

103

104

105

106

Sbit, Bitumen Stiffness Modulus (N/m2)

Figure 1. Influence of aggregate roundness on rutting potential of asphalt con-

crete mixtures.

2

to contents

Previous Page

Previous Page