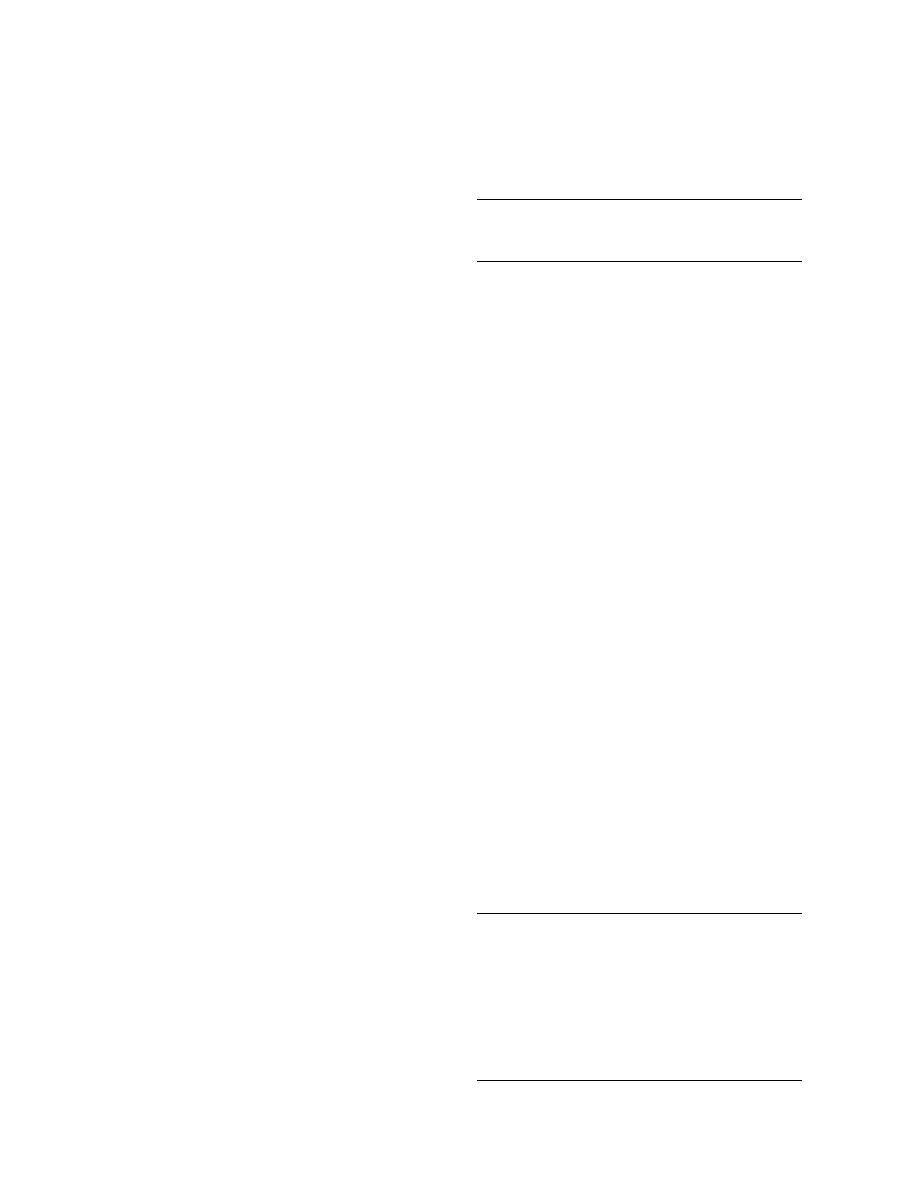

Table 3. Comparison of δ13C and δ15N values for

duce isotopic fractionation. Two methods had to

be developed, one for soil samples and one for

TNT subjected to different sample preparation

water samples. The goal of each method was

processes.

exhaustive extraction with no isotopic fraction-

δ13C

δ15N

ation, because if this occurred during sample

preparation, it would confound the results.

Control solution

28.2

3.41

For soil samples, the most efficient means of

SPE cartridge extract

28.0

3.42

exhaustive extraction is the Soxhlet extractor.

Soxhlet extract

28.2

3.41

Although Soxhlet extractions are slow, this tech-

nique has the unique characteristic that the

analytes are completely separated from the soil in

the δ13C values for TNT, although varied, are not

the extractor because the solvent reservoircollec-

greatly affected by the changing concentration.

tion vessel and sample holder are physically sepa-

The result for the 1.96-g/L (2.0-ng) standard

rated. In the case of ultrasonic extraction, the

shows a dramatic increase in the δ13C value for

sample and extraction solvent are in the same ves-

TNT (Table 4). These data indicate that, below a

sel. Complete (100%) removal of the solvent for

concentration threshold of 4 mg/L, the δ13C value

an ultrasonic extraction is not possible. Some

for TNT takes on a concentration dependency. This

residual solvent remains with the sample and this

dictates that all analyses require an injection mass

solvent will contain some of the analytes. With

of 4 ng or greater.

Soxhlet extraction, once the analytes are passed to

the collection vessel, they cannot again come in

Analysis of TNT from multiple sources

contact with the soil. The results of an extraction

TNT was obtained from several sources, provid-

kinetics experiment showed that a 24-hour extrac-

ing SARM, technical grade, and three military

tion was required to obtain 99.9% recovery of TNT

grade samples. Solutions of each material were

from field contaminated soil using AcN as the

analyzed to determine the δ13C and δ15N values

extraction solvent.

for TNT. The objective of this experiment was to

For extraction of TNT from water samples, solid

establish a working range for these values using

phase extraction (SPE) was the method of choice.

real material that may be present at a TNT-con-

The groundwater was passed through an SPE car-

taminated site. The results are presented in Table

tridge at 10 mL/min and the analytes were recov-

5 and Figure 2.

ered with 5 mL of AcN. The recovery for TNT was

There were significant differences in both the

99.8%.

δ

13C and δ15N values for TNT among the differ-

Spiked soil and water samples were prepared

ent sources. These differences can be attributed to

and processed using the methods described above.

the actual materials used to produce each TNT and

The extracts from these samples were analyzed to

determine the δ13C and δ15N values for TNT. These

the level of refinement for each. The SARM grade

results were compared to the δ13C and δ15N val-

is noticeably the most different. It is also the most

highly refined. For the military grade samples, the

ues for TNT dissolved in solution at the same con-

centration as the extracts. Results for both tech-

niques showed that there was no isotopic

Table 4. Concentration of TNT in solution ver-

sus δ13C value for TNT.

fractionation during the sample preparation pro-

cesses (Table 3)

δ13C value

Concentration

Mass of

of TNT

TNT injected

for TNT

Calibration study

(mg/L)

(ng)

(‰)

The concentration of TNT in moist soil samples

is known to decrease with time under certain

1001

1000

31.9

environmental conditions (Grant et al. 1993). Thus,

501

501

31.2

the mass of TNT recovered over a time course

250

250

28.5

125

125

29.6

experiment will decline as time passes. The objec-

62.5

62.5

27.9

tive of this calibration experiment was to deter-

31.3

31.3

26.2

mine if δ13C values for TNT in solution varied as

15.6

15.6

25.4

a function of concentration or mass injected into

7.8

7.8

29.4

the analyzer. The results in Table 4 show that,

3.9

3.9

34.5

1.96

2.0

17.2

above 4.0 mg/L (or 4.0 ng injected) in solution,

8

Previous Page

Previous Page