(Rong 1996) and empirical (Hewitt 1998b) mod-

touched the water when the soil-gas sample was

els.

added; thus, the formation of bubbles confirmed

Table 6 shows the conversion coefficients (CO)

that a vapor sample was being transferred.

Table 4 shows that the rates of loss for several

between soil-vapor and soil matrix concentra-

analytes were only about 2% per day of storage.

tions for TCE that have been established in this

Furthermore, the rate of loss was fairly constant,

study and previously. The value for this field

thus a correction factor could be used to restore

study agrees well with the mean value based on

values to day 1 concentrations. Perhaps even

a theoretical model (Rong 1996) and is bracketed

slower rates of vapor loss would have been es-

by those based on a laboratory study (Hewitt

tablished if the sample vials were refrigerated,

1998b). Indeed, the value of 0.806 established for

frozen (12 3C), or treated with an acidified

this study fits between those established in the

solution saturated with sodium chloride. Fur-

laboratory study for soil from the same site,

thermore, the presence of two holes

had no effect because working stan-

Table 5. Soil vapor and collocated soil matrix concentra-

dards prepared with and without

tions.

two holes in the septum frequently

gave the same response.

Sample Soil sample

Triplicate values

Average soil vapor

number (mg TCE/kg)

(mg TCE/L)

(mg TCE/L)*

In general, this storage and hand-

ling system works better than Tedlar

0.019 0.0012 (6.1%)

1

0.021

0.018 0.020 0.018

0.030 0.0

bags (Wang et al. 1996) but not as

2

0.057

0.030 0.030 0.030

(0.0%)

0.043 0.0015 (3.6%)

3

0.051

0.041 0.043 0.044

well as passivated Summa canisters

0.14 0.012 (8.2%)

4

0.18

0.13 0.15 0.15

(Wang and Clifford 1991). However,

0.43 0.031 (7.1%)

5

0.28

0.46 0.40 0.42

neither of these other methods of

2.1 0.20 (9.5%)

†

6

1.7

1.9

2.1

2.3

storing VOC vapors is well suited for

3.7 0.26 (7.2%)

7

3.6

3.4

3.9

3.8

4.8 0.67

soil-gas studies of in-situ concentra-

8

8.1

5.6

4.4

4.5

(14%)

12 1.4

9

11

11

13 NA

(12%)

tions in discrete locations because of

7.8 0.75 (9.6%)

10

12

7.1

8.6

7.8

the volume of sample that is

7.3 0.23 (3.2%)

11

14

7.2

7.6

7.2

required.

12 0.53 (4.8%)

12

16

12

12

13

The data in Table 5 also show that

15 0.0

13

16

15

15

15

(0.0%)

15 1.2

soil-vapor TCE concentrations did

14**

19

14

16

14

(7.7%)

26 1.0

††

15

28

25

27

26

(3.8%)

not appear to become diluted after as

24 2.0

16

32

22

24

26

(8.3%)

many as nine sequential samples

were taken at a single place (location

* Average, standard deviation, and relative standard deviation.

† First equilibriumtemporal study.

14; the subsamples in Table 5 were

** Nine replicate soil-vapor samples collected at this location.

the first, fifth and ninth taken). This

†† Second equilibriumtemporal study.

indicates that a longer probe, with a

NA Sample lost.

larger dead volume, would also be

effective, thus allowing even greater

30

depths to be sampled.

30

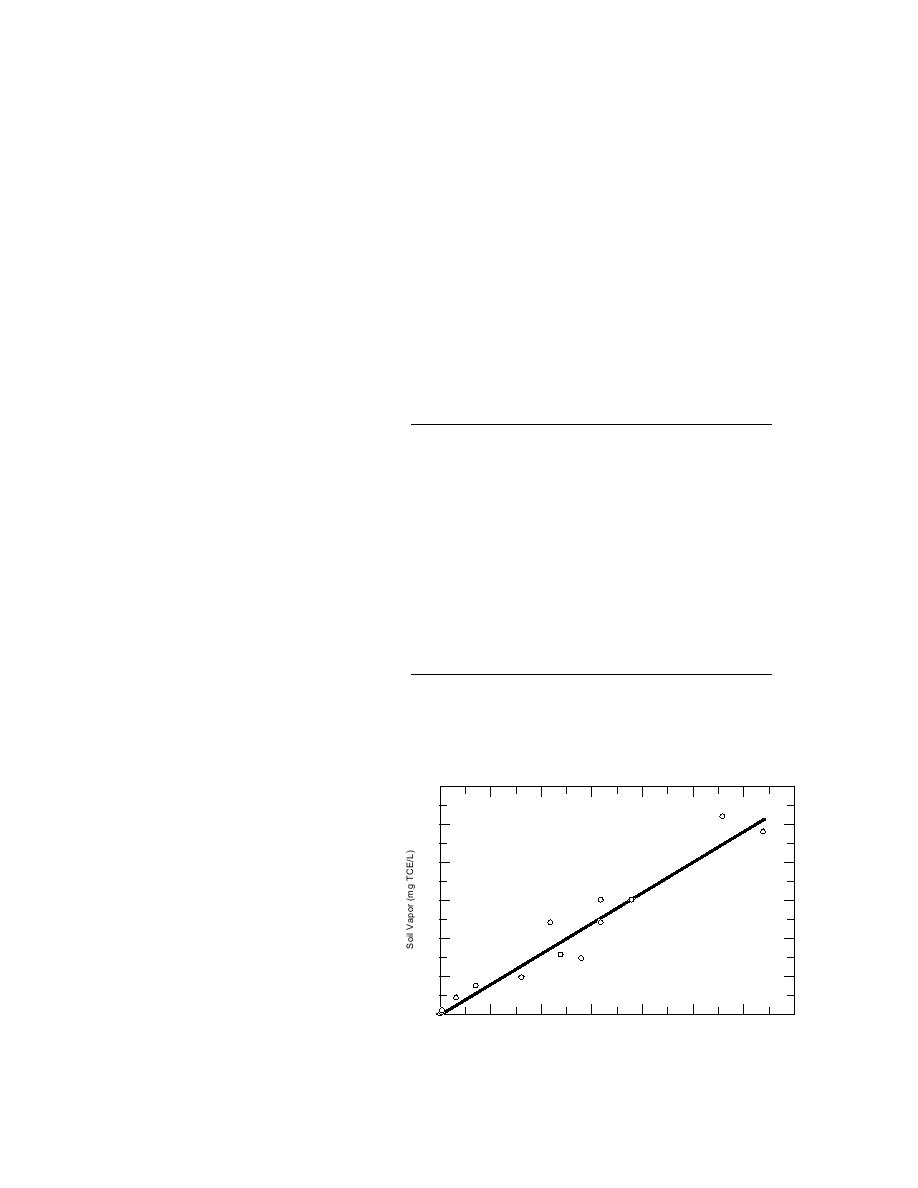

The comparison between TCE

25

concentrations in soil-vapor samples

25

and collocated moist soil matrix sam-

20

ples appears in Table 5 and Figure 2.

20

The precision of this sample collec-

15

tion, handling, and analysis method

15

was very good. Frequently (14 out of

10

16 times), a relative standard devia-

y = (0.8055)x

R2==(0..9504)x

0 8055

y

10

tion of less than 10% was obtained for

R2 = 0.9504

5

the triplicate measurements. The lin-

5

ear and highly significant correlation

(r2= 0.950) established between these

0

00

5005

500

10000

0

15000

0

20000

2020

25000

25 0

30000

30 0

35000

3535

1010

1515

0

0

25

30

two methods of characterizing va-

Soi GrabS mpl l gg TC TCE/kg)

SSollilGraabSaampee((m/(mgE/kg)

o Gr b Sample Kg)

dose zone VOC contamination is Figure 2. Correlation between mean soil-vapor TCE concentrations

consistent with both theoretical and soil matrix TCE concentations.

7

Previous Page

Previous Page