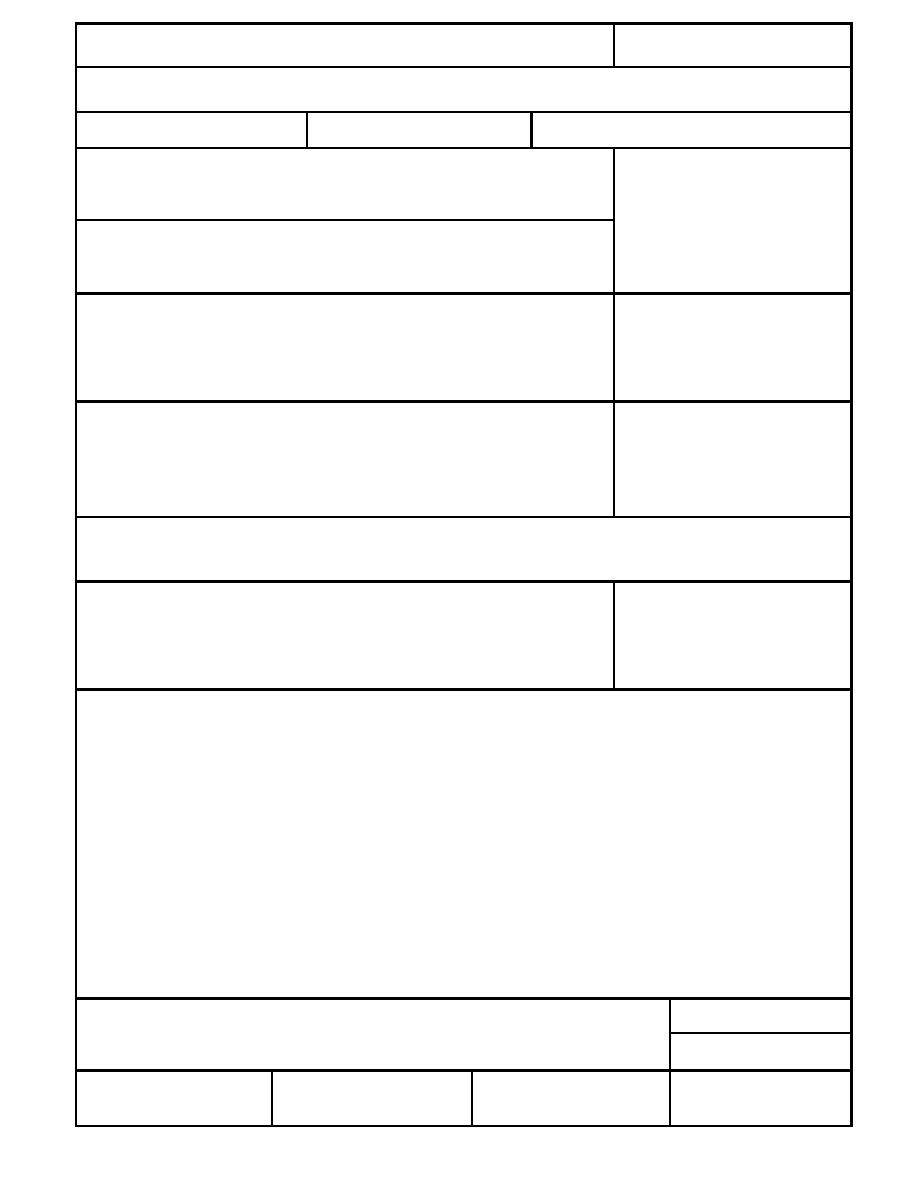

Form Approved

REPORT DOCUMENTATION PAGE

OMB No. 0704-0188

Public reporting burden for this collection of information is estimated to average 1 hour per response, including the time for reviewing instructions, searching existing data sources, gathering and

maintaining the data needed, and completing and reviewing the collection of information. Send comments regarding this burden estimate or any other aspect of this collection of information,

including suggestion for reducing this burden, to Washington Headquarters Services, Directorate for Information Operations and Reports, 1215 Jefferson Davis Highway, Suite 1204, Arlington,

VA 22202-4302, and to the Office of Management and Budget, Paperwork Reduction Project (0704-0188), Washington, DC 20503.

1. AGENCY USE ONLY (Leave blank)

2. REPORT DATE

3. REPORT TYPE AND DATES COVERED

August 1997

4. TITLE AND SUBTITLE

5. FUNDING NUMBERS

Increasing Cold Weather Masonry Construction Productivity

6. AUTHORS

Charles J. Korhonen, Robert D. Thomas, and Edel R. Cortez

7. PERFORMING ORGANIZATION NAME(S) AND ADDRESS(ES)

8. PERFORMING ORGANIZATION

REPORT NUMBER

U.S. Army Cold Regions Research and Engineering Laboratory

72 Lyme Road

Special Report 97-16

Hanover, New Hampshire 03755-1290

9. SPONSORING/MONITORING AGENCY NAME(S) AND ADDRESS(ES)

10. SPONSORING/MONITORING

AGENCY REPORT NUMBER

Office of the Chief of Engineers

Washington, D.C. 20314-1000

For conversion of SI units to non-SI units of measurement consult Standard Practice for Use of the

11. SUPPLEMENTARY NOTES

International System of Units (SI), ASTM Standard E380-93, published by the American Society for Testing and Materials,

1916 Race St., Philadelphia, Pa. 19103.

12a. DISTRIBUTION/AVAILABILITY STATEMENT

12b. DISTRIBUTION CODE

Approved for public release; distribution is unlimited.

Available from NTIS, Springfield, Virginia 22161.

13. ABSTRACT (Maximum 200 words)

The thermal protection requirements for cold weather masonry, as established in current industry specifica-

tions, were evaluated. Experiments were conducted to define the most relevant factors in the process of

freezing of newly placed mortar. The effect of unit absorption on the moisture content of mortar during the

first hours after assembly was assessed. Correlations of moisture content with time were developed for

mortar in contact with masonry units. Frost immunity thresholds in terms of mortar moisture content and

in terms of maturity were determined. The test results provided the basis for new proposed guidance on

when fresh mortar can be safely exposed to freezing temperatures. Test methods for evaluation of the

freezethaw resistance of masonry units were evaluated. A new test was proposed and adopted by ASTM

as a new standard test for the freezethaw testing of masonry units. In addition, several chemicals were

evaluated for their potential as antifreeze admixtures for masonry mortar. Antifreeze admixtures were first

developed for use in concrete, but the practicality of using antifreeze admixtures in masonry mortars was

demonstrated in a field application in Michigan during the winter.

14. SUBJECT TERMS

15. NUMBER OF PAGES

58

Antifreeze admixture

Thermal protection

Cold-weather masonry

Winter construction

16. PRICE CODE

Freezethaw

17. SECURITY CLASSIFICATION

18. SECURITY CLASSIFICATION

19. SECURITY CLASSIFICATION

20. LIMITATION OF ABSTRACT

OF REPORT

OF THIS PAGE

OF ABSTRACT

UNCLASSIFIED

UNCLASSIFIED

UNCLASSIFIED

UL

Standard Form 298 (Rev. 2-89)

NSN 7540-01-280-5500

Prescribed by ANSI Std. Z39-18

298-102

Previous Page

Previous Page