20

25

a.

b.

x

+

Mat'l. No. and

x

Saturation Moist. Cont. (%)

+

1 (0.4 %)

20

2 (0.5)

+

x

15 +

x

x

3 (0.3)

4 (0.5)

+

x

5 (0.5)

x

+

15

x

+

+

+++ + +

x

x

x

10

x

+

10

xx xx x

xx

+ +++

++

x

x

+

5

++

x

x

5

+

x

0

2 0

0

1

10

20

0

50

100

150

200

250

Saturation

Passing 200 Sieve (%)

Hours of Freezing

Moisture Content (%)

U.S. Std. Sieve Size and No.

Hydrometer

3

3

4

4

10

40

200

100

80

4

(0.5 %)

60

40

3 (0.3)

1 (0.4)

20

2 (0.5)

5 (0.5)

0

1.0

0.1

0.01

0.001

0

100

10

Grain Size (mm)

Gravel

Sand

Silt or Clay

C'rse

Fine

C'rse

Medium

Fine

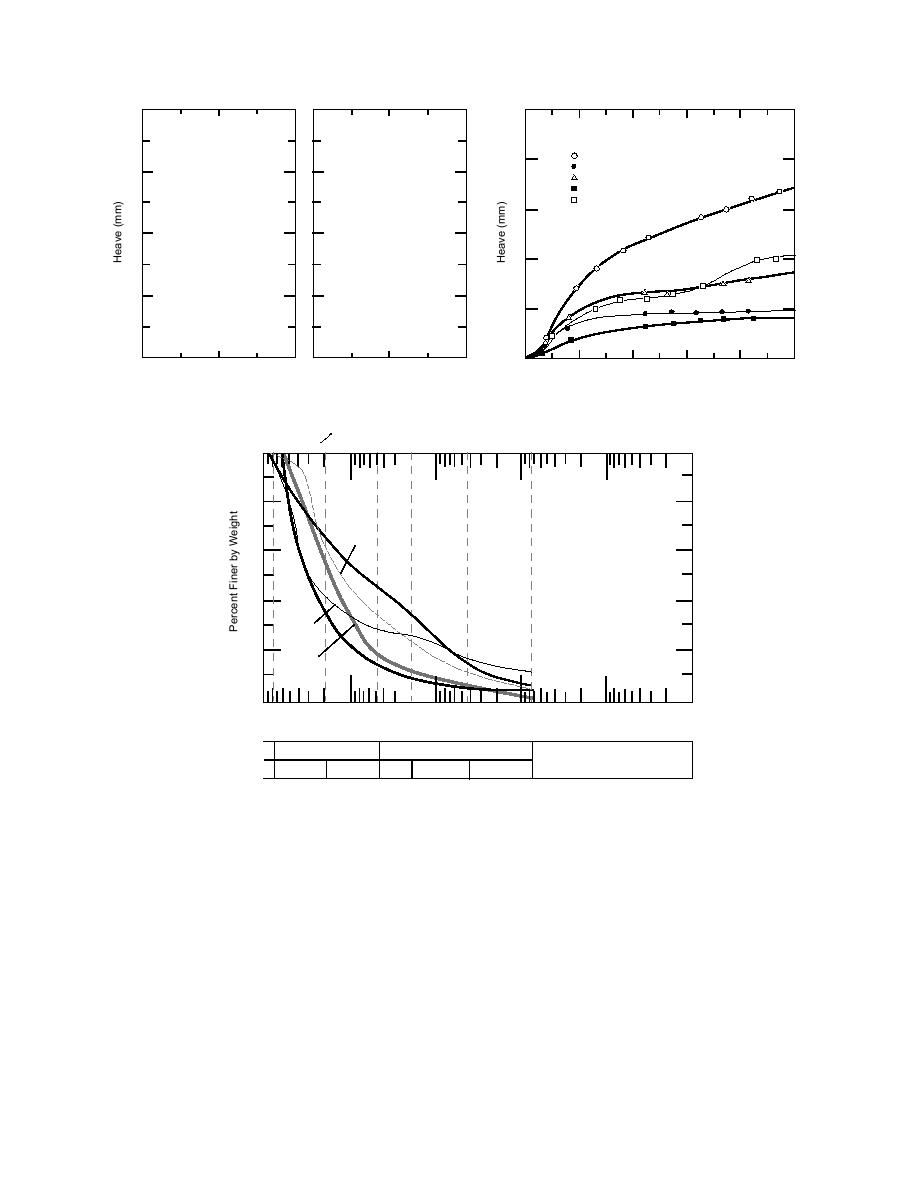

Figure 8. Frost heave of hard limestones (1 in. = 25.4 mm).

Adding lime to clay soils causes the structure of

are soil type, quantity of cement, degree of mixing

the clay to flocculate. In the lime-stabilized mix-

and time of curing (Yoder and Witzcak 1975). Of

ture, after a chemical reaction with water (pozzo-

all the factors mentioned above, the cure time is

the critical factor. For example, after 20 days, a 5%

lanic action), cementation takes place, perhaps

through calcium silicate or aluminate bonding.

soil (CL) and cement mixture acquired an uncon-

The addition of a pozzolan, such as fly ash to lime,

fined compressive strength of approximately 4100

kPa (600 lb/in.2), and a 10% soilcement mixture

speeds up the cementation process and also pro-

duces extra strength. However, the quantities of

reached an approximate unconfined compressive

strength of 5500 kPa (800 lb/in.2). The amount of

fly ash required are generally high, 1020% (Yoder

and Witzcak 1975). The amount of lime added is

portland cement used for strength improvement

about 2 to 5% by weight.

varies around 915% for sandy soils, base, and

Portland cement, when added to soils, hardens

subbase and around 59% for clean clays. Highly

the mixture through hydration of the cement. Fac-

plastic soils (CH) may require 1520% cement by

tors that affect the portland cementsoil mixture

weight to bring about hardening.

13

Previous Page

Previous Page