locations: on grade next to the slabs, and overhead

Cost comparison

in the heated enclosure. A concrete testing labora-

Freeze protection is the primary cost-multiplier

tory (Coleman Engineering Co., Iron Mountain,

of a concrete job done during the winter. Based on

Michigan) periodically tested the cylinders' com-

the field tests, the main differences between nor-

mal winter concreting practice at the Soo and con-

pressive strength.

creting done with antifreeze admixtures are the

Their compressive strengths cannot be used as

heat, shelter, and labor needed to protect the nor-

an indicator of the in-place strength of the anti-

mal concrete, and the chemicals in the antifreeze

freeze concrete because, as Figure 4f shows, the

concrete. Table 5 shows an estimate of the relative

cylinders probably froze. At CRREL, subsequent

surcharge, per slab, of each winter concreting

petrographic analysis of the suspected frozen

method. It is useful to know that the cost of ready-

cylinders revealed typical ice lens patterns.

mix concrete at the Soo was .50/m3 the sum-

Strengths reported by the testing laboratory indi-

mer before this project and that placement would

cate that the cylinders developed only about half

double this cost.

of their potential strength, which is indicative of

concrete that has frozen while curing.

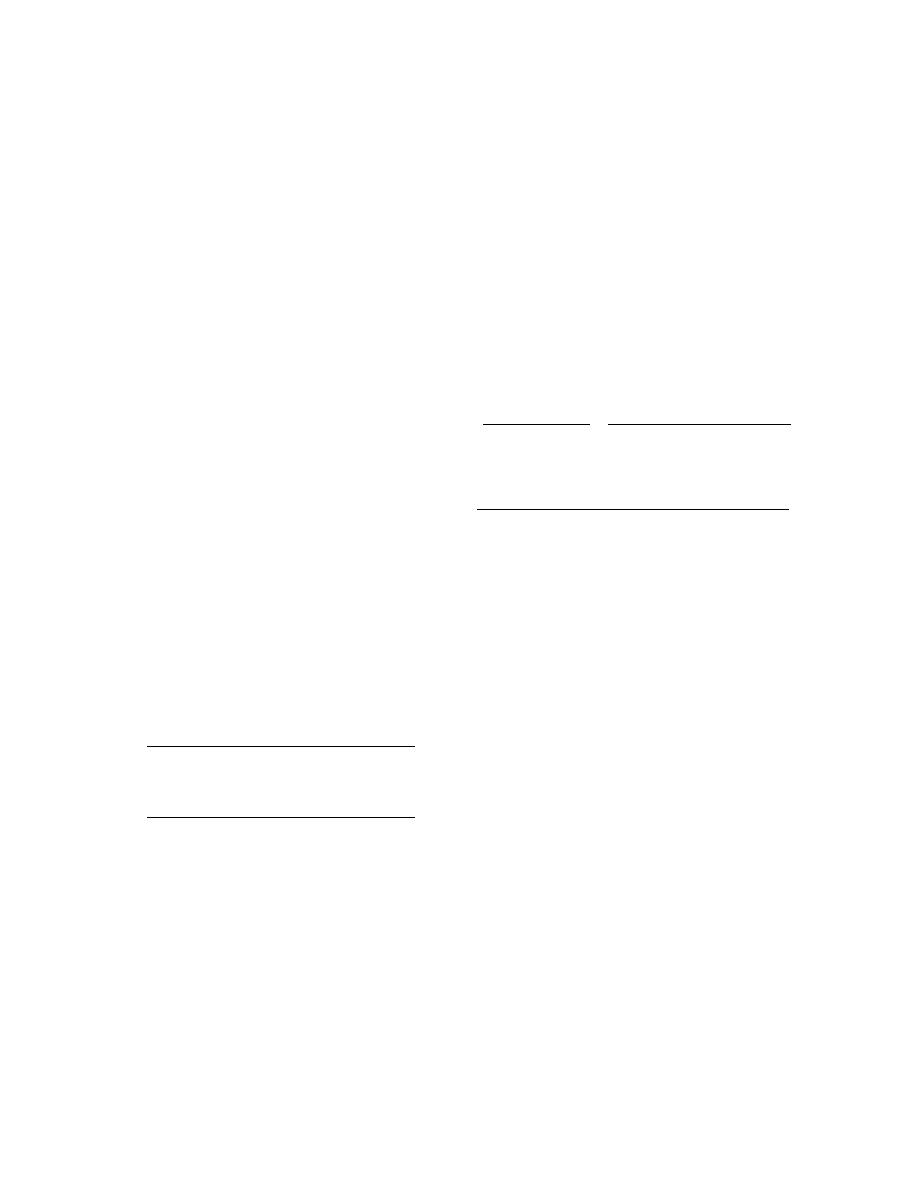

Table 5. Winter surcharge estimate per slab.

Likewise, the strengths of the cylinders stored

overhead in the heated shelter were not consid-

Shelter

Antifreeze

ered useful information, other than to confirm

5.1 m3

that the admixtures promoted strength in concrete

Erect

2

Concrete

Materials

8

Dosage

97.1mL/kg cement

cured at above-freezing temperatures. They shed

391 kg/m3

Heat

6

Cement

little light on the in-place strength of the concrete

Dismantle

6

Admixture

||content||

.80.10/Lslabs.

Total

82

Total

57

The most interesting and useful results came

from cores drilled from each slab in the summer.

DISCUSSION

The cores showed that the antifreeze concrete was

Normal unprotected concrete would have fro-

at least as good as the control concrete in compres-

zen during this test. The freezing-point-depres-

sive strength and appearance. None of the slabs

sion and accelerated cure properties of the anti-

showed signs of frost damage and all of the con-

freeze concretes enabled them to resist freezing.

crete exceeded minimum design strengths (Table

The best evidence that the concrete did not

4). In fact, when it is considered that entrained

freeze was obtained by examining drilled cores.

Table 4. Test results from 9.2- 13.3-cm

The core samples, taken from each slab 4 months

core samples drilled in July 1994.

after construction and examined under a micro-

scope, showed no signs of frost damage.

Compressive

Bulk

density†

strength*

Evidence of

The drilled cores were also tested for compres-

(g/cm3)

past ice?

Mix

(Mpa)

sive strength, which provided additional infor-

mation that the admixtures produced a concrete

Control

46.7

2.31

No

DP

46.0

2.21

No

that was unaffected by the outdoor winter condi-

EY11L

50.6

2.32

No

tions.

EY11H

55.5

2.29

No

Other than the cold weather, the major concern

* Minimum design strength was 32 Mpa.

during the test was that concrete was placed on a

† Densities based on cylinder dimensions and

subgrade that was significantly below the 5C

mass.

protection capability of the admixtures at their

highest dosage, let alone at the low dosage. This

air can reduce compressive strength 3% for each

could mean that the bottom of the concrete would

1% of entrained air (U.S. Department of the Interi-

be damaged by frost. Gavrish et al. (1974) report-

or, Water and Power Resources Service 1981; Kos-

ed that up to 16 times more heat is lost from a con-

matka and Panarese 1988), and that the air con-

crete slab to frozen ground than is lost to the air

tents were generally higher in the admixtured

during initial curing. From our data, however, it

concretes than in the control concrete (Table 3), the

was clear that the bottom of the concrete was free

strength of the admixtured concretes exceeded the

from frost damage. The lowest slab-bottom tem-

strength of the control concrete. Though air con-

perature of the low dosage EY11 concrete was

tents can change when a concrete hardens, the

about 1.2C, 21 hours after placement, and for

core densities (Table 4) suggest that the concretes

the high dosage EY11 concrete it was 2.6C, 4

retained their relative proportions of air.

8

Previous Page

Previous Page