separate phase as aqueous con-

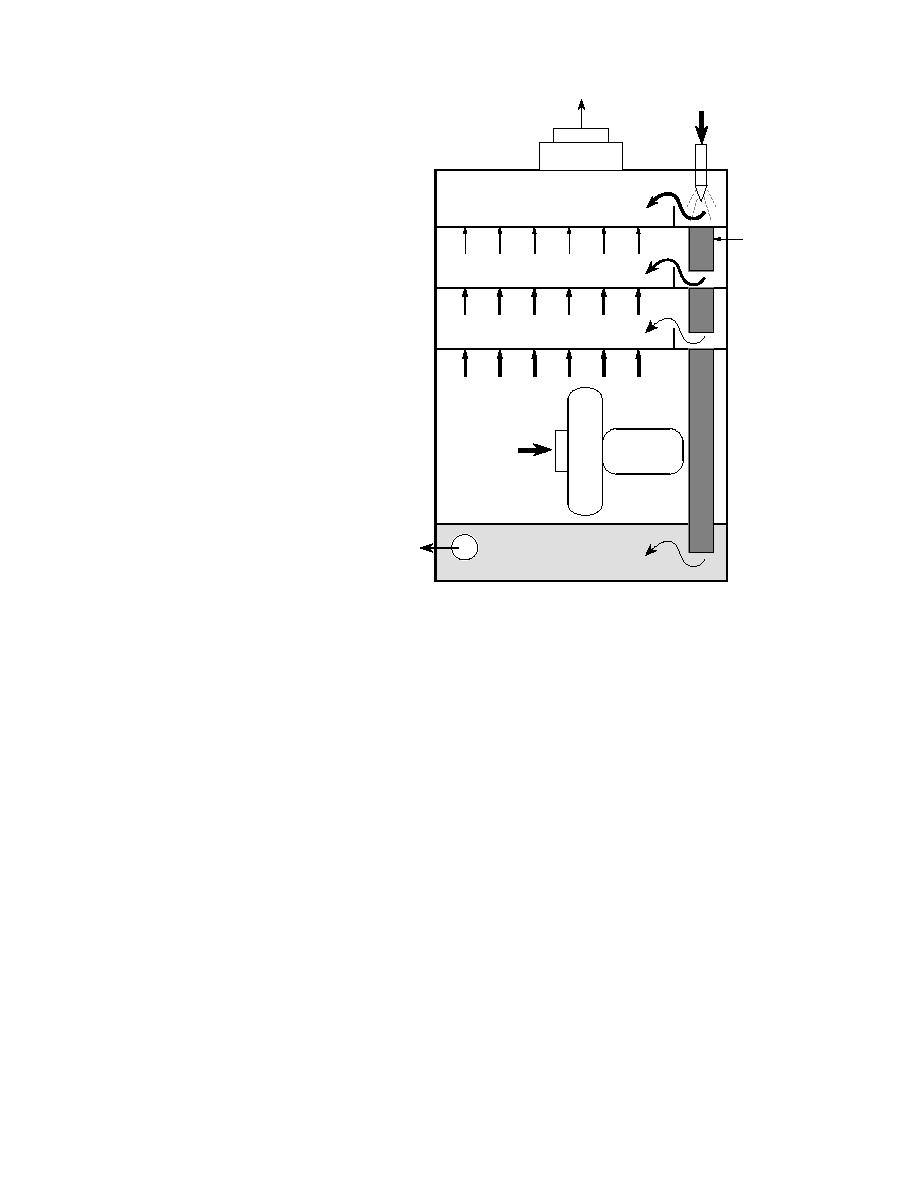

Air

Contaminated Water

taminants (API 1976). This separate

Inlet

phase frequently requires another

removal process in remediation

Spray

schemes.

Nozzle

Separate phase or "free product"

petroleum can be removed by basic

Water

oil/water separators, which are

Flow

readily available and relatively in-

Downcomer

expensive. High performance oil/

water separators are available that

Aeration Trays

(maximum of four)

can theoretically remove enough

separate phase and soluble petro-

leum to meet most state discharge

permits (approximately 1 mg/L),

but they are very expensive and may

employ materials which would be

Air Flow

damaged by exposure to VOCs like

Water Holding

chlorinated solvents (Hackman

Tank

1978).

Liquid-phase adsorption of pe-

Clean Air Intake

Blower

troleum hydrocarbons is a common

industrial application, and has been

compared favorably to vapor-phase

hydrocarbon adsorption (API 1983).

However, neither liquid nor vapor Clean Water

phase adsorption is the best method

Outlet

for all petroleum hydrocarbon re-

moval applications. Sorption sites

on activated carbon can be limited Figure 1. Air stripping process; counter-current air and water flow in

during liquid-phase adsorption by tray-type air stripper.

aqueous suspended solids (API

1983). Vapor-phase adsorption can have a signifi-

are met by a counter-current flow of air blown in

cant cost advantage when treating highly con-

from the bottom of the tower.

taminated groundwaters, because it allows lower

During the past five years, compact, low-pro-

contaminant loading rates and minimizes inor-

file air strippers have gained increasing accep-

ganic loading to the adsorbent, which in turn maxi-

tance and now represent more than half of the air

mizes its useful life (API 1983).

strippers used at new remediation sites (Lamarre

1993). The most common style of low profile air

stripper is the tray-type unit in which a shallow

Air stripping systems

Air stripping is the most commonly used liq-

layer of water is allowed to flow along one or

uid-to-gas mass transfer method for VOCs. Air

more trays as noted in Figure 1. Air is blown

stripping of BTEX compounds has been widely

through hundreds of holes in the bottom of the

successful, but only steam stripping and high tem-

trays to generate a froth of bubbles--a large mass

perature air stripping (HTAS) have been consid-

transfer surface area where the contaminants are

ered feasible for treating less volatile organics like

volatilized. In the tray-type, low-profile aeration

long-chain hydrocarbons (Fleming 1989, U.S. EPA

system the air performs two functions: 1) creating

1991). Inside the most common type of air strip-

the interfacial surface area (created by the pack-

pers, i.e., packed towers, high liquid surface area

ing in a packed tower) and 2) volatilizing the

is created by pumping water to the top of a hol-

contaminants. This feature of the tray-type air

low tower and allowing it to trickle over a dumped

stripper is advantageous when treating waters

packing inside. The water spreads over the pack-

that contain high concentrations of soluble

ing as it flows downward, creating a thin, high

inorganics. In the tray-type unit, metal oxide pre-

surface area film. The thin films on the packing

cipitates are easily cleaned from the smooth stain-

2

Previous Page

Previous Page