either side of the joint from an applied load. Load (or

stress) transfer is the ratio of amount of stress that is

transferred across the joint. For a perfect transfer,

50% of the stress is transferred across the joint.

From his study, Foxworthy (1985) reported the fol-

lowing:

1. JTE increased with increasing temperature and

the relationship between JTE and temperature was the

same whether he used air or pavement temperatures.

2. The type of joint construction affected the rate at

which LTE changed with temperature.

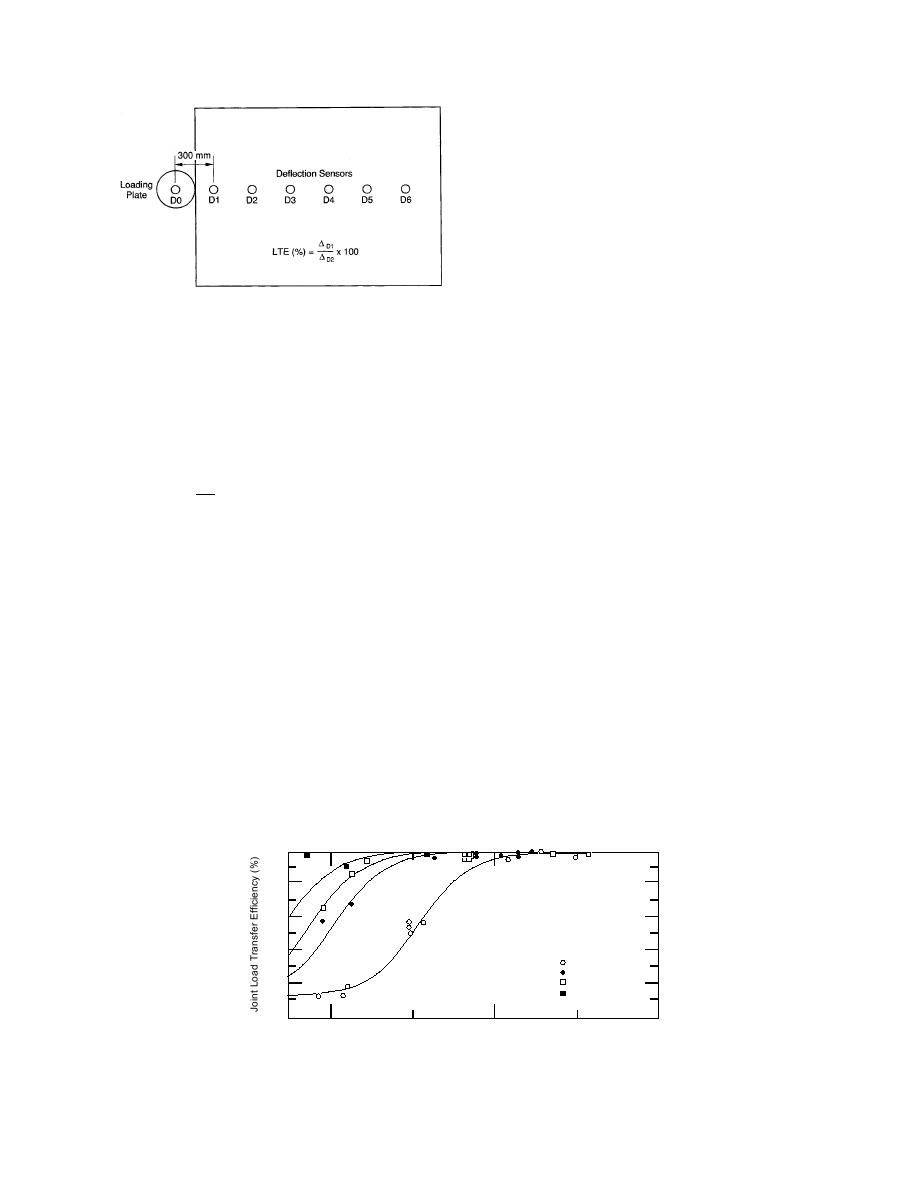

Figure 38. Placement of FWD sensors for load trans-

3. The JTE was not affected by the FWD load used

fer efficiency test.

during the test.

4. The JTE was the same across transverse joints

to determine the amount of deflection on either side of

when measured from the approach or leave slab on

the joint as illustrated in Figure 37.

airfield pavements (see Fig. 37). However, across lon-

The Corps of Engineers' method (TM 5-826-5, U.S.

gitudinal joints, the LTE values were higher when

measured from the leave slab.

Army, no date) for calculating the Joint Transfer Effi-

Foxworthy (1985) developed relationships for pre-

ciency (JTE) using the deflections obtained with the

dicting the LTE. He found that, in general, an S type

FWD is

curve could be used to fit his results concerning load

δ1

JTE =

transfer efficiency and temperature (Fig. 39). The

δ0

JTEtemperature relationships obtained by Foxwor-

thy were from tests conducted at different times of the

where JTE = joint transfer efficiency

δ0 = center plate deflection

day where the only changes that were occurring were

δ1 = deflection measured across joint.

in the PCC layer. Since the base and subgrade

strengths were changing very little with time, these

results may not be applicable to pavements during

With the FWD, the center sensor was placed on one

thaw-weakening periods. So, we used the limited data

side of the joint and the second sensor, located 300 mm

away from the center of the loading plate, was placed

collected at OCA and CWA to study the effects of

across the joint. This is illustrated in Figure 38. The

changing subbasesubgrade stiffness during spring

JTE values across the transverse, longitudinal and cor-

thaw on JTE.

ner joints, as calculated from the equation above for

Loads were transferred across transverse joints

both CWA and OCA, are presented in Tables 11 and

with dowels or aggregate interlocks and across longi-

12. The JTE values presented in the tables are the aver-

tudinal joints by the use of keyways, aggregate inter-

age from the four drop heights (joint and load transfer

locks or tiebars. Typical changes at CWA are shown in

have been used interchangeably in the literature). In

Figures 40 and 41. We found two basic trends at CWA

this report, a distinction is made between joint (JTE)

and only the first at OCA:

and load transfer efficiency (LTE). Joint transfer effi-

1. In general, the transverse JTE increased with in-

ciency as shown above is the ratio of the deflections on

creasing temperature, similar to that reported by Fox-

100

80

60

40

Slab No. 1

2

3

20

4

0

4.4

26.7

48.9

Air Temperature (C)

Figure 39. Relationship between air temperature and transverse joint

transfer efficiency (after Foxworthy 1985).

31

Previous Page

Previous Page