from the immediate flanks of the

airstrip and thus had a high con-

centration of ice chunks that had

been removed from the runway

during construction.) We used the

heavy pneumatic-tire roller to com-

pact this snow in 10- to 15-cm lifts;

this also acted to mix well the ice

and snow so that the ice chunks

were more uniformly distributed

throughout the cover. The surface

was planed and dragged to leave a

smooth and porous surface.

The 199394 season at Pegasus

was more typical of what we ex-

pect would be a normal operational

year. Because the annual sea ice

runway at McMurdo provides eco-

nomical access for wheeled aircraft

at the beginning of the season, the

Pegasus runway is not required

until after about 15 December.

Thus, the snow that covers the run-

way throughout the winter, and

any extra snow that is encourage

to collect between early September

and late November (if it is needed)

remains on the runway until it is

safe to remove based on the guide-

lines established for prevention of

melt. By using natural means of

snow collection, much less effort is

required, but attention must be

paid for a longer period of time.

A survey of the runway snow

cover in late August 1993 indicated

that the winter had provided an

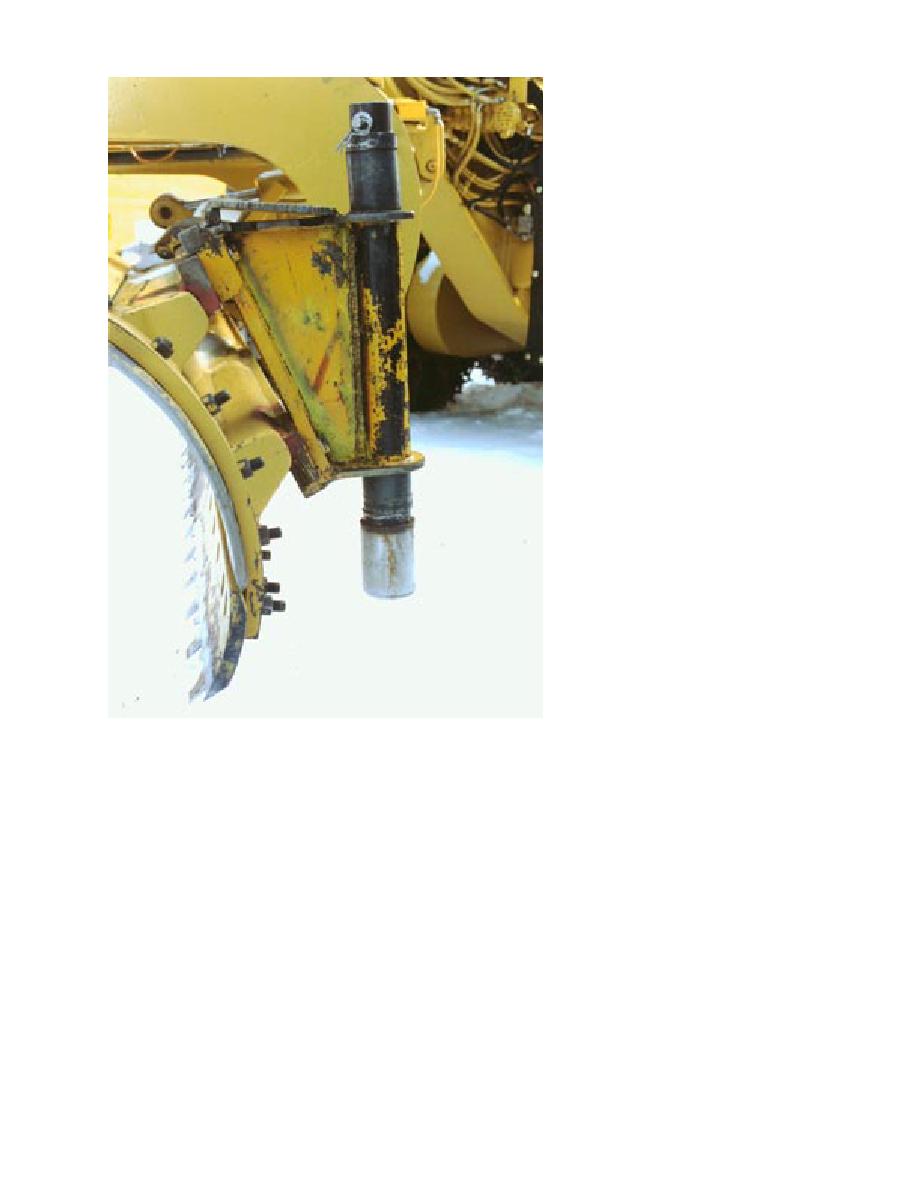

Figure 80. Adjustable skids used to assist in "floating" grader blade.

average of about 30 cm (12 in.) of

snow. However, this snow was in

ice on or about the beginning of January. During

no way uniformly distributed. The centerline was

our first operational season (199293), construc-

exposed along nearly the entire length of the run-

tion was not completed until the end of October.

way. Along the edges, the runway had tapered

We used the snowblower, operating along the

drifts that diminished in height as they extended

flanks of the runway, to move a snow/ice mix-

toward the centerline. Many small drift pods (<10

m2) were randomly scattered across the remain-

ture back onto the runway for protection. The

der of the surface. In addition, the south half of

bulldozers and grader with skids (feet) (Fig. 29

the runway had notably more snow accumula-

and 80) were used to spread the snow uniformly

tion than the northern portion. We used the rip-

over the ice surface. This operation required about

per with skids (Fig. 30) to loosen the drift snow.

three weeks to complete. Thus, based on our

This was followed by the grader and bulldozers

guidelines, we were about 10 days late in getting

the snow cover in place. This created consider-

with skids, and then the snow plane and drags, to

able concern which was compounded by the high

redistributed the snow and smooth the surface.

ice-chunk content in the protective snow cover.

This process took about two weeks to accomplish

(The snow blown back onto the runway came

using a crew of four persons.

76

Previous Page

Previous Page