PVC in building and construction

PVC has been used extensively in the building and construction industry for over fifty years.

Vinyl windows have become very common. Other applications include fencing, railing, decking,

floor and wall covering, cladding, and roofing. Because it is fairly impermeable, it is also used as

a vapor barrier for trapping moisture inside the wall cavity. Flexible vinyl is used for sheathing

electric cables and wires.

Fire performance

The fire performance of PVC depends largely on the exact combinations of additives and

modifiers. Especially for use as insulating material for electrical use, PVC must meet the fire

safety requirements of the National Fire Protection Association's National Electrical Code. The

high chlorine content of the PVC makes it inherently more flame resistant than most alternative

materials in the electrical product industry. However, vinyl electrical products typically burn at

above 600F when a flame or heat source is applied, but they usually self-extinguish when the

flame source is removed (Vinyl by Design, 2003). When it burns, PVC releases significantly less

heat than many other electrical insulation and jacketing materials. Like many other similar

products, PVC's combustion products are toxic. Burning produces carbon dioxide and carbon

monoxide; the latter is extremely toxic.

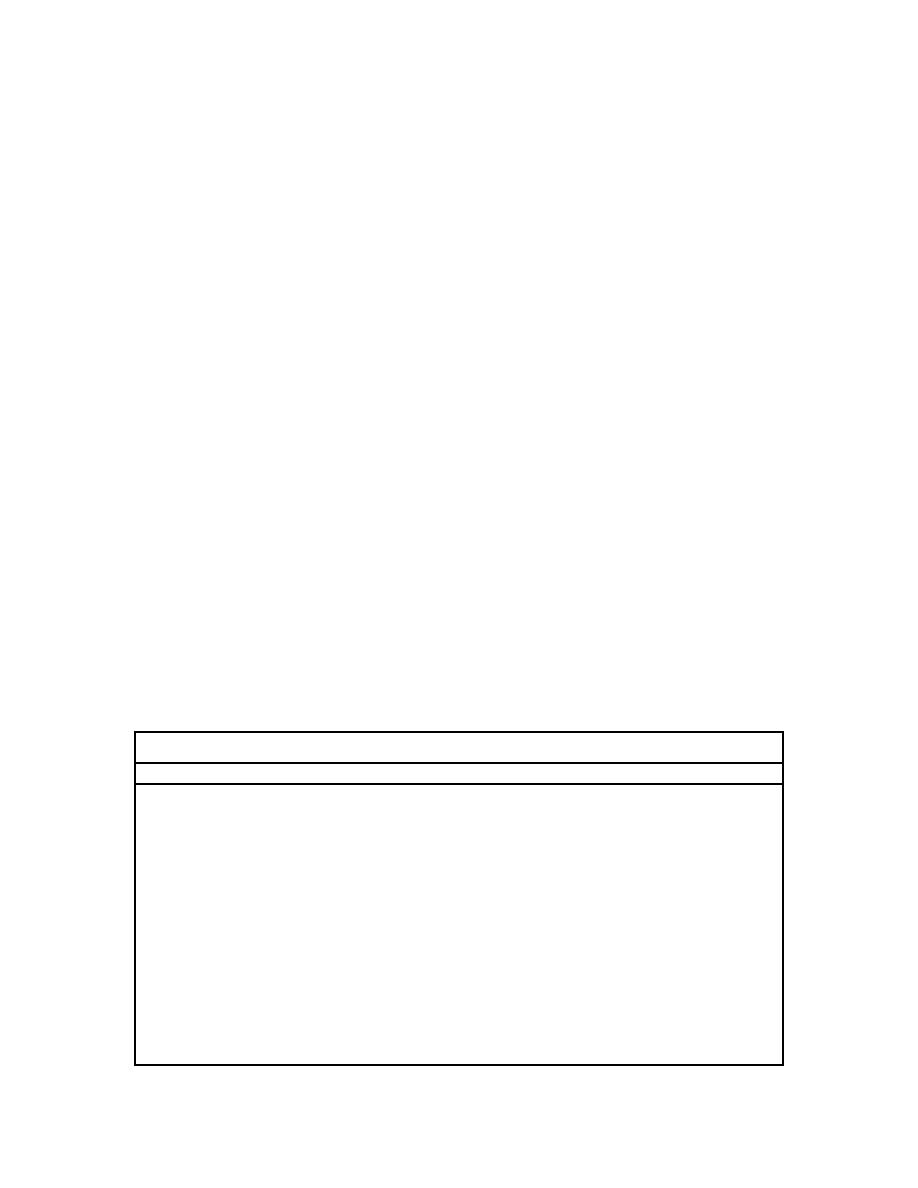

Comparison of properties of PVC and steel

In mechanical properties steel is far superior to PVC. Table 1 compares the main mechanical

properties of steel and PVC. PVC is about six times lighter but ten times weaker than steel. The

tensile modulus of PVC is about one eightieth that of steel, so for a given load and beam shape,

PVC deflects about 80 times more than the steel. However, the weight advantage, the advantage

of better electrical insulation (which is an important consideration for lightning protection), and

lower cost make PVC attractive for many situations. A comparison of the properties of steel and

PVC is given graphically in Figure 3 and schematically as stressstrain curves with approximate

properties in Figure 4.

Table 1. Comparison of the mechanical properties of steel and PVC.

Properties

Steel

Rigid PVC (ASTM method)

5880 103

Tensile strength at break (psi)

5,9007,500 (D638)

Elongation at break (%)

21

4080 (D638)

36 103

Tensile yield strength (psi)

5,9006,500 (D638)

Compressive strength (psi)

8,00013,000 (D695)

Flexural strength (psi)

10,00013,000 (D790)

30 106

350600 103 (D638)

Tensile modulus (psi)

300300 103 (D790)

Flexural modulus (psi)

Izod impact (ft-lb/in. of notch)

12

0.42.2 (D256A)

131 (Brinell)

6585 (D2240) (shore)

15.12 106

50100 106 (D696)

Coefficient of themal expansion (in./in. C)

Heat deflection temperature (F)

140170 (D648)

6.7

3.55.0 (C177)

Density (lb/in3)

0.283

0.0460.056 (D792)

Water absorption (24 hr) (%)

0.040.40 (D570)

5

Previous Page

Previous Page