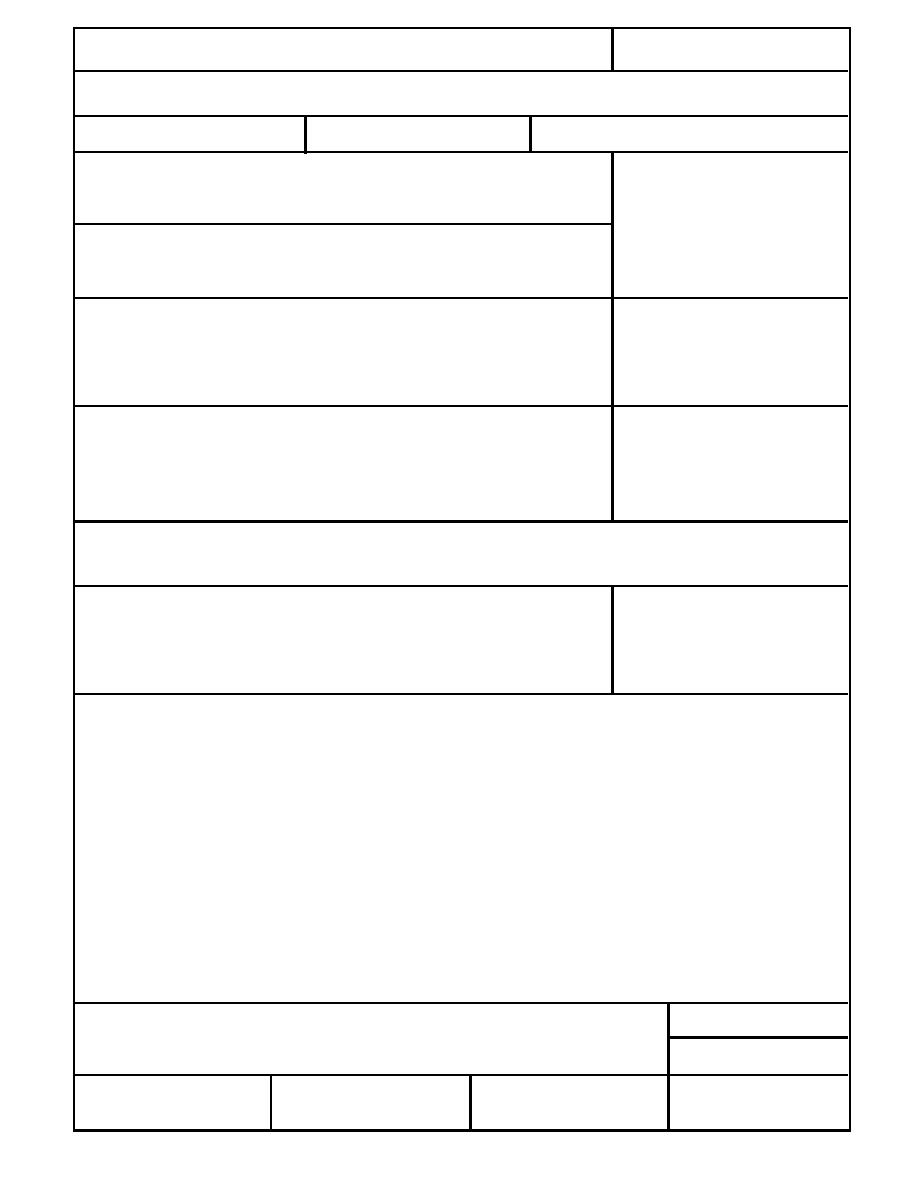

Form Approved

REPORT DOCUMENTATION PAGE

OMB No. 0704-0188

Public reporting burden for this collection of information is estimated to average 1 hour per response, including the time for reviewing instructions, searching existing data sources, gathering and

maintaining the data needed, and completing and reviewing the collection of information. Send comments regarding this burden estimate or any other aspect of this collection of information,

including suggestion for reducing this burden, to Washington Headquarters Services, Directorate for Information Operations and Reports, 1215 Jefferson Davis Highway, Suite 1204, Arlington,

VA 22202-4302, and to the Office of Management and Budget, Paperwork Reduction Project (0704-0188), Washington, DC 20503.

1. AGENCY USE ONLY (Leave blank)

2. REPORT DATE

3. REPORT TYPE AND DATES COVERED

August 1998

4. TITLE AND SUBTITLE

5. FUNDING NUMBERS

Investigations of Plastic Composite Materials for Highway Safety Structures

DTFH61-90-Y-00035

6. AUTHORS

Piyush K. Dutta

7. PERFORMING ORGANIZATION NAME(S) AND ADDRESS(ES)

8. PERFORMING ORGANIZATION

REPORT NUMBER

U.S. Army Cold Regions Research and Engineering Laboratory

72 Lyme Road

CRREL Report 98-7

Hanover, New Hampshire 03755-1290

9. SPONSORING/MONITORING AGENCY NAME(S) AND ADDRESS(ES)

10. SPONSORING/MONITORING

AGENCY REPORT NUMBER

Federal Highway Administration

6300 Georgetown Pike

McLean, Virginia 22101

FHWA-RD-98-060

11. SUPPLEMENTARY NOTES

For conversion of SI units to non-SI units of measurement, consult ASTM Standard E380-93, Standard Practice for Use of the

International System of Units, published by the American Society for Testing and Materials, 100 Barr Harbor Drive., West

Conshohocken, Pennsylvania 19428-2959.

12a. DISTRIBUTION/AVAILABILITY STATEMENT

12b. DISTRIBUTION CODE

Approved for public release; distribution is unlimited.

Available from NTIS, Springfield, Virginia 22161

13. ABSTRACT (Maximum 200 words)

This report presents a basic overview and assessment of different concepts and technologies of using polymer

composites in structures generally used for highway safety. The structural systems included a highway barrier

guardrail with its posts and blockouts, sign posts, concrete reinforcing rebars, breakaway couplers, and crushable

plastic cushions to protect errant drivers from roadside sign and utility posts, and small trees. The composites

included fiber reinforced plastics (FRP) in laminated and bar forms, and commercially available recycled and

reconstituted structural plastic composites. Commercially available FRP composites, recycled plastic composites,

and several conceptual designs and prototype components were assessed and tested. The results showed many

potential advantages of using composites in almost all the structures considered, but one-to-one replacement of

conventional materials was not always found attractive. For deriving maximum benefits from fiber composites,

the basic performance of the given structures should be reassessed and then composites should be designed at

the materials level using innovative fiber architecture and appropriate manufacturing technologies that can meet

those performance requirements.

14. SUBJECT TERMS

15. NUMBER OF PAGES

85

Breakaway supports, Composites, Crush cushions, Guardrails, FRP, Highway barriers,

16. PRICE CODE

Highway safety structures, New materials, Rebars, Recycled plastics, Roadside safety

17. SECURITY CLASSIFICATION

18. SECURITY CLASSIFICATION

19. SECURITY CLASSIFICATION

20. LIMITATION OF ABSTRACT

OF REPORT

OF THIS PAGE

OF ABSTRACT

UNCLASSIFIED

UNCLASSIFIED

UNCLASSIFIED

UL

Standard Form 298 (Rev. 2-89)

NSN 7540-01-280-5500

Prescribed by ANSI Std. Z39-18

298-102

Previous Page

Previous Page