APPENDIX B: CRASH TESTING OF RPC POSTS AND BLOCKOUTS

Report on the crash testing of RPC posts and blockouts at the

Federal Outdoor Impact Laboratory (FOIL) at TFHRC in McLean, Virginia.

Extract from reference McDevitt and Dutta (1993)

"In order to investigate the suitability of

was expected because wood posts also break

Rivenite posts and blockouts for guardrails, a 100-

under these test conditions. However, since the

ft- (30.5-m-) long test section of guardrail was con-

Rivenite posts are nonfibrous, they broke cleanly

structed at the Federal Outdoor Impact Labora-

in a horizontal plane at groundline. The test data

tory (FOIL) at TFHRC in McLean, Virginia. The

met all of the evaluation criteria in National

upstream end of the guardrail was anchored with

Cooperative Highway Research Program Report

a 37.5-ft- (11.4-m-) long BCT. A cable anchorage

No. 230 (Michie 1981). The maximum lateral

was used on the downstream end. The 6-in 8-in.

deflection of the guardrail was two ft (609 mm).

(152-mm 203-mm) Rivenite posts were driven

Under the same test conditions, a guardrail with

into the ground by a subcontractor that special-

wood posts and blockouts deflected ten in (254

izes in constructing guardrails. It was found that

mm) (AASHTO, 1977). This test indicates that the

the Rivenite posts could readily be driven, but they

Rivenite posts are not a one-for-one substitute

required about twice as many hammer blows as

for either the Douglas fir or the Southern Yellow

wood posts. This was due to the greater energy

Pine wood posts that are used in this guardrail

absorption of the Rivenite material. When driven,

system (AASHTO, 1977).

the posts retained their shape and did not mush-

Each guardrail system has its own characteris-

room out on the bottom end. In appearance, this

tic design deflection. For example, the G1 3-cable

guardrail looked very much like the G4 (2w)

guardrail has a design deflection of 11 ft (3.4 m)

W-beam on strong wood post guardrail used by

(AASHTO, 1977). This guardrail with Rivenite

many states (AASHTO, 1977 and 1989).

posts and blockouts can be thought of as a new

In October 1991, this guardrail was crash-tested

guardrail system that will have its own unique

with an 1,800-lb (816 kg) car at 60 mi/h (96.5

design deflection. However, since the FOIL facility

km/h) at an impact angle of 20. The test vehicle

does not have the capability to conduct tests with

was redirected parallel to the guardrail. Several

full-size sedans, the crash test needed to investi-

Rivenite posts were broken in the impact zone and

gate the strength of this guardrail and establish

flew away from the back of the guardrail. This

its design deflection has not yet been conducted."

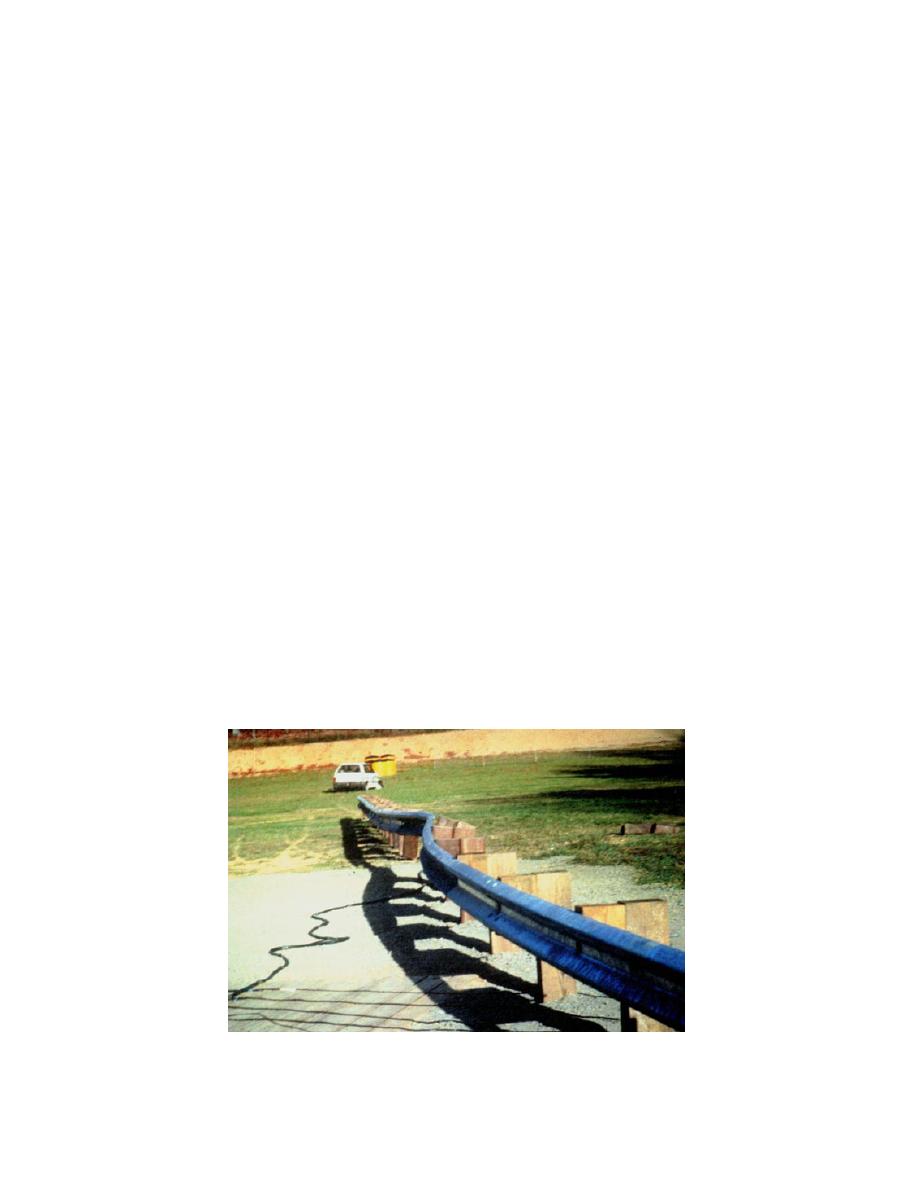

Figure B1. Crash testing of RPC posts and blockouts at the FHWA FOIL

Laboratory.

72

Previous Page

Previous Page