29

Leaf Spring

8

Groove for

Leaf Spring

Inner Facing

32

4

8

8

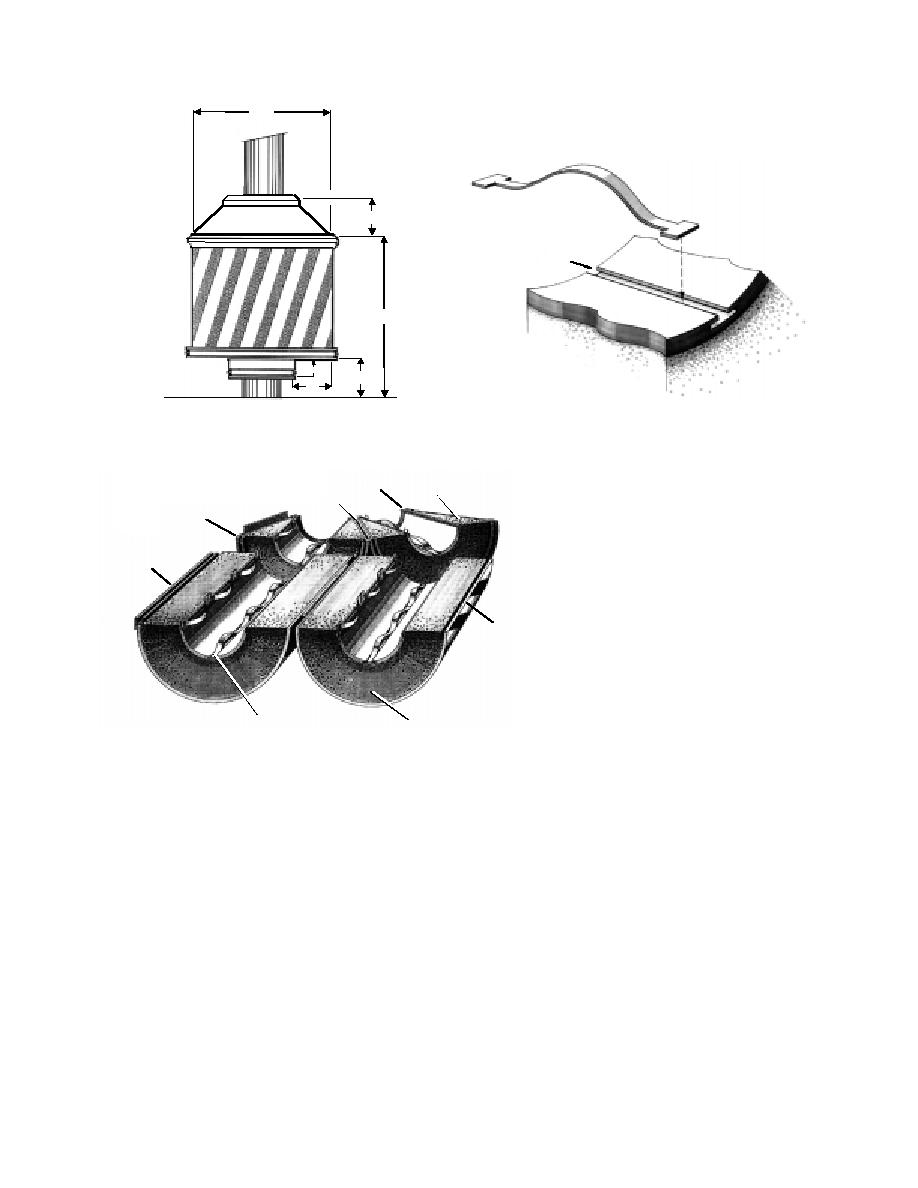

Figure 73. Overall view of the concep-

Figure 75. Details of the leaf spring and its T-groove on

tual crushable plastic cushion. (Dimen-

the inner facing.

sions are in inches.)

74) mounted directly above the cylin-

Cap

Cap Gasket

Cushion

drical body cushion will allow exces-

Hinge

sive snow and water to drain, and will

Shoulder Gasket

protect the crushable foam from exces-

sive moisture and dirt. The cap cush-

H-Section

Rubber Gasket

ion would be made of two hubs joined

by a hinge. The cutout grooves in the

foam surface of both the body cushion

and the cap cushion will allow a spe-

Reflective

cially profiled shoulder gasket to seal

Decal Sheet

the cap cushion onto the body cushion

(Fig. 72). The annulus between the

inner facing and the pole will provide

the dripping path for melted snow or

Leaf Spring

rainwater. A specially molded polyure-

Body Cushion

Figure 74. Illustration of the two halves of the crushable plastic

thane cap gasket configured with appro-

cushion split open.

priate grooves and lips, and slit from

the center, will serve as the top end-cap

of the conical cap cushion. The bottom end-cap

hubs of rigid high-density closed-cell polypropy-

(Fig. 76) will also be made of molded polyurethane

lene foam sandwiched between two FRP facings

in two halves. The outer facing of the body cush-

(Fig. 74). Both the outer facing and inner facing

ion will fit into the recess of the bottom end-cap,

will be made of vinyl-ester-impregnated, chopped-

which will be clamped together with a stainless-

glass-reinforced molded product. The outer fac-

steel band clamp. Another stainless-steel band

ings of the two hubs will be joined with a full-

clamp of smaller diameter will tightly clamp the

length hinge to allow the two hubs to close around

neck portion of the bottom end-cap onto the pole.

the rigid pole. A longitudinal groove in the foam

The bottom end-cap will provide openings

on each hub will allow an H-section rubber gas-

between the radial ribs through which water drip-

ket to seal the longitudinal open joint of the outer

ping from the pole can pass down. The outer sur-

facings. Along the length of the inner facing, lon-

face of the outer FRP facing will have a bonded

gitudinal T-grooves, molded in during casting,

reflective decal sheet for easy recognition of the

will receive a series of three stainless-steel leaf

crush cushion at night or low lighting. Special care

springs (Fig. 75). The leaf springs in four such

has been taken in this design to make it adapt-

slots, spaced at 90 apart, will hold the cushion in

able not only to fixed posts, but also to small or

place against the pole. A conical cap cushion (Fig.

53

Previous Page

Previous Page